PDF Publication Title:

Text from PDF Page: 011

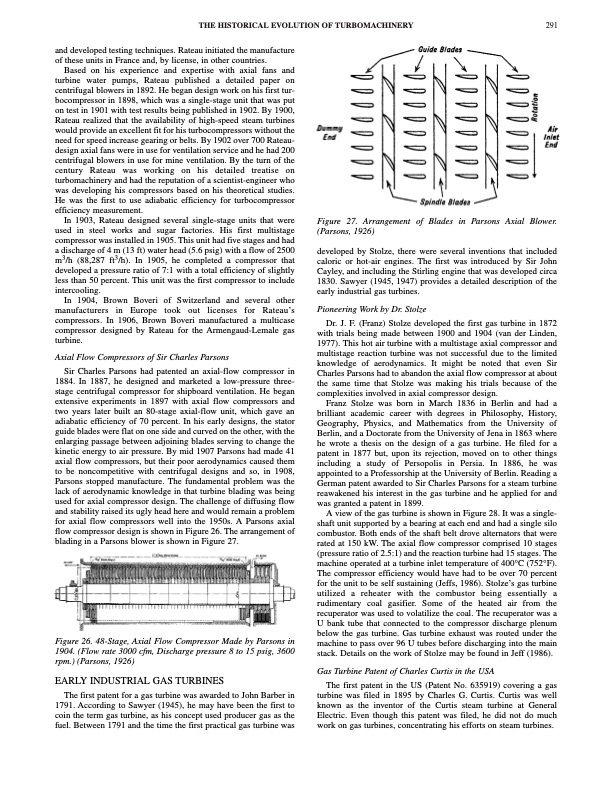

THE HISTORICAL EVOLUTION OF TURBOMACHINERY 291 and developed testing techniques. Rateau initiated the manufacture of these units in France and, by license, in other countries. Based on his experience and expertise with axial fans and turbine water pumps, Rateau published a detailed paper on centrifugal blowers in 1892. He began design work on his first tur- bocompressor in 1898, which was a single-stage unit that was put on test in 1901 with test results being published in 1902. By 1900, Rateau realized that the availability of high-speed steam turbines would provide an excellent fit for his turbocompressors without the need for speed increase gearing or belts. By 1902 over 700 Rateau- design axial fans were in use for ventilation service and he had 200 centrifugal blowers in use for mine ventilation. By the turn of the century Rateau was working on his detailed treatise on turbomachinery and had the reputation of a scientist-engineer who was developing his compressors based on his theoretical studies. He was the first to use adiabatic efficiency for turbocompressor efficiency measurement. In 1903, Rateau designed several single-stage units that were used in steel works and sugar factories. His first multistage compressor was installed in 1905. This unit had five stages and had a discharge of 4 m (13 ft) water head (5.6 psig) with a flow of 2500 m3/h (88,287 ft3/h). In 1905, he completed a compressor that developed a pressure ratio of 7:1 with a total efficiency of slightly less than 50 percent. This unit was the first compressor to include intercooling. In 1904, Brown Boveri of Switzerland and several other manufacturers in Europe took out licenses for Rateau’s compressors. In 1906, Brown Boveri manufactured a multicase compressor designed by Rateau for the Armengaud-Lemale gas turbine. Axial Flow Compressors of Sir Charles Parsons Sir Charles Parsons had patented an axial-flow compressor in 1884. In 1887, he designed and marketed a low-pressure three- stage centrifugal compressor for shipboard ventilation. He began extensive experiments in 1897 with axial flow compressors and two years later built an 80-stage axial-flow unit, which gave an adiabatic efficiency of 70 percent. In his early designs, the stator guide blades were flat on one side and curved on the other, with the enlarging passage between adjoining blades serving to change the kinetic energy to air pressure. By mid 1907 Parsons had made 41 axial flow compressors, but their poor aerodynamics caused them to be noncompetitive with centrifugal designs and so, in 1908, Parsons stopped manufacture. The fundamental problem was the lack of aerodynamic knowledge in that turbine blading was being used for axial compressor design. The challenge of diffusing flow and stability raised its ugly head here and would remain a problem for axial flow compressors well into the 1950s. A Parsons axial flow compressor design is shown in Figure 26. The arrangement of blading in a Parsons blower is shown in Figure 27. Figure 26. 48-Stage, Axial Flow Compressor Made by Parsons in 1904. (Flow rate 3000 cfm, Discharge pressure 8 to 15 psig, 3600 rpm.) (Parsons, 1926) EARLY INDUSTRIAL GAS TURBINES The first patent for a gas turbine was awarded to John Barber in 1791. According to Sawyer (1945), he may have been the first to coin the term gas turbine, as his concept used producer gas as the fuel. Between 1791 and the time the first practical gas turbine was Figure 27. Arrangement of Blades in Parsons Axial Blower. (Parsons, 1926) developed by Stolze, there were several inventions that included caloric or hot-air engines. The first was introduced by Sir John Cayley, and including the Stirling engine that was developed circa 1830. Sawyer (1945, 1947) provides a detailed description of the early industrial gas turbines. Pioneering Work by Dr. Stolze Dr. J. F. (Franz) Stolze developed the first gas turbine in 1872 with trials being made between 1900 and 1904 (van der Linden, 1977). This hot air turbine with a multistage axial compressor and multistage reaction turbine was not successful due to the limited knowledge of aerodynamics. It might be noted that even Sir Charles Parsons had to abandon the axial flow compressor at about the same time that Stolze was making his trials because of the complexities involved in axial compressor design. Franz Stolze was born in March 1836 in Berlin and had a brilliant academic career with degrees in Philosophy, History, Geography, Physics, and Mathematics from the University of Berlin, and a Doctorate from the University of Jena in 1863 where he wrote a thesis on the design of a gas turbine. He filed for a patent in 1877 but, upon its rejection, moved on to other things including a study of Persopolis in Persia. In 1886, he was appointed to a Professorship at the University of Berlin. Reading a German patent awarded to Sir Charles Parsons for a steam turbine reawakened his interest in the gas turbine and he applied for and was granted a patent in 1899. A view of the gas turbine is shown in Figure 28. It was a single- shaft unit supported by a bearing at each end and had a single silo combustor. Both ends of the shaft belt drove alternators that were rated at 150 kW. The axial flow compressor comprised 10 stages (pressure ratio of 2.5:1) and the reaction turbine had 15 stages. The machine operated at a turbine inlet temperature of 400°C (752°F). The compressor efficiency would have had to be over 70 percent for the unit to be self sustaining (Jeffs, 1986). Stolze’s gas turbine utilized a reheater with the combustor being essentially a rudimentary coal gasifier. Some of the heated air from the recuperator was used to volatilize the coal. The recuperator was a U bank tube that connected to the compressor discharge plenum below the gas turbine. Gas turbine exhaust was routed under the machine to pass over 96 U tubes before discharging into the main stack. Details on the work of Stolze may be found in Jeff (1986). Gas Turbine Patent of Charles Curtis in the USA The first patent in the US (Patent No. 635919) covering a gas turbine was filed in 1895 by Charles G. Curtis. Curtis was well known as the inventor of the Curtis steam turbine at General Electric. Even though this patent was filed, he did not do much work on gas turbines, concentrating his efforts on steam turbines.PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |