PDF Publication Title:

Text from PDF Page: 012

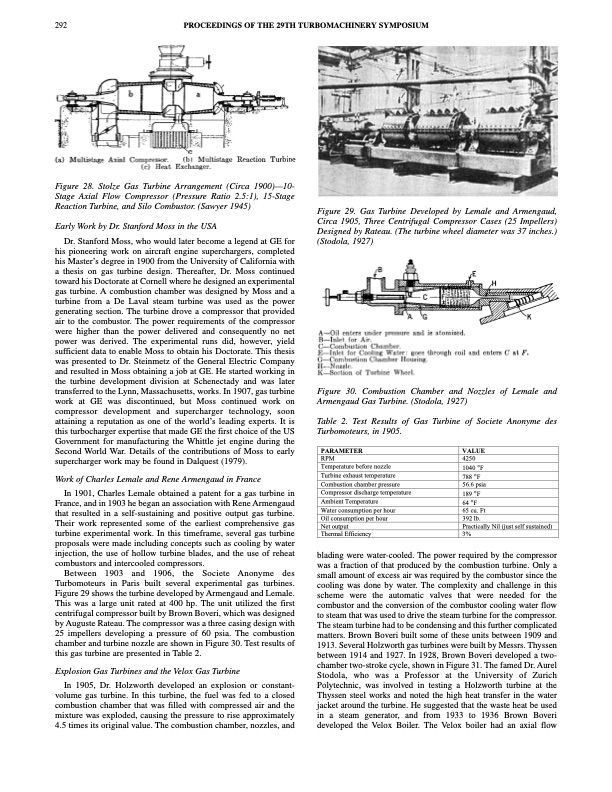

292 PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM Figure 28. Stolze Gas Turbine Arrangement (Circa 1900)—10- Stage Axial Flow Compressor (Pressure Ratio 2.5:1), 15-Stage Reaction Turbine, and Silo Combustor. (Sawyer 1945) Early Work by Dr. Stanford Moss in the USA Dr. Stanford Moss, who would later become a legend at GE for his pioneering work on aircraft engine superchargers, completed his Master’s degree in 1900 from the University of California with a thesis on gas turbine design. Thereafter, Dr. Moss continued toward his Doctorate at Cornell where he designed an experimental gas turbine. A combustion chamber was designed by Moss and a turbine from a De Laval steam turbine was used as the power generating section. The turbine drove a compressor that provided air to the combustor. The power requirements of the compressor were higher than the power delivered and consequently no net power was derived. The experimental runs did, however, yield sufficient data to enable Moss to obtain his Doctorate. This thesis was presented to Dr. Steinmetz of the General Electric Company and resulted in Moss obtaining a job at GE. He started working in the turbine development division at Schenectady and was later transferred to the Lynn, Massachusetts, works. In 1907, gas turbine work at GE was discontinued, but Moss continued work on compressor development and supercharger technology, soon attaining a reputation as one of the world’s leading experts. It is this turbocharger expertise that made GE the first choice of the US Government for manufacturing the Whittle jet engine during the Second World War. Details of the contributions of Moss to early supercharger work may be found in Dalquest (1979). Work of Charles Lemale and Rene Armengaud in France In 1901, Charles Lemale obtained a patent for a gas turbine in France, and in 1903 he began an association with Rene Armengaud that resulted in a self-sustaining and positive output gas turbine. Their work represented some of the earliest comprehensive gas turbine experimental work. In this timeframe, several gas turbine proposals were made including concepts such as cooling by water injection, the use of hollow turbine blades, and the use of reheat combustors and intercooled compressors. Between 1903 and 1906, the Societe Anonyme des Turbomoteurs in Paris built several experimental gas turbines. Figure 29 shows the turbine developed by Armengaud and Lemale. This was a large unit rated at 400 hp. The unit utilized the first centrifugal compressor built by Brown Boveri, which was designed by Auguste Rateau. The compressor was a three casing design with 25 impellers developing a pressure of 60 psia. The combustion chamber and turbine nozzle are shown in Figure 30. Test results of this gas turbine are presented in Table 2. Explosion Gas Turbines and the Velox Gas Turbine In 1905, Dr. Holzworth developed an explosion or constant- volume gas turbine. In this turbine, the fuel was fed to a closed combustion chamber that was filled with compressed air and the mixture was exploded, causing the pressure to rise approximately 4.5 times its original value. The combustion chamber, nozzles, and Figure 29. Gas Turbine Developed by Lemale and Armengaud, Circa 1905, Three Centrifugal Compressor Cases (25 Impellers) Designed by Rateau. (The turbine wheel diameter was 37 inches.) (Stodola, 1927) Figure 30. Combustion Chamber and Nozzles of Lemale and Armengaud Gas Turbine. (Stodola, 1927) Table 2. Test Results of Gas Turbine of Societe Anonyme des Turbomoteurs, in 1905. blading were water-cooled. The power required by the compressor was a fraction of that produced by the combustion turbine. Only a small amount of excess air was required by the combustor since the cooling was done by water. The complexity and challenge in this scheme were the automatic valves that were needed for the combustor and the conversion of the combustor cooling water flow to steam that was used to drive the steam turbine for the compressor. The steam turbine had to be condensing and this further complicated matters. Brown Boveri built some of these units between 1909 and 1913. Several Holzworth gas turbines were built by Messrs. Thyssen between 1914 and 1927. In 1928, Brown Boveri developed a two- chamber two-stroke cycle, shown in Figure 31. The famed Dr. Aurel Stodola, who was a Professor at the University of Zurich Polytechnic, was involved in testing a Holzworth turbine at the Thyssen steel works and noted the high heat transfer in the water jacket around the turbine. He suggested that the waste heat be used in a steam generator, and from 1933 to 1936 Brown Boveri developed the Velox Boiler. The Velox boiler had an axial flow PARAMETER VALUE RPM 4250 Temperature before nozzle 1040 °F Turbine exhaust temperature 788 °F Combustion chamber pressure 56.6 psia Compressor discharge temperature 189 °F Ambient Temperature 64 °F Water consumption per hour 65 cu. Ft Oil consumption per hour 392 lb. Net output Practically Nil (just self sustained) Thermal Efficiency 3%PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |