PDF Publication Title:

Text from PDF Page: 015

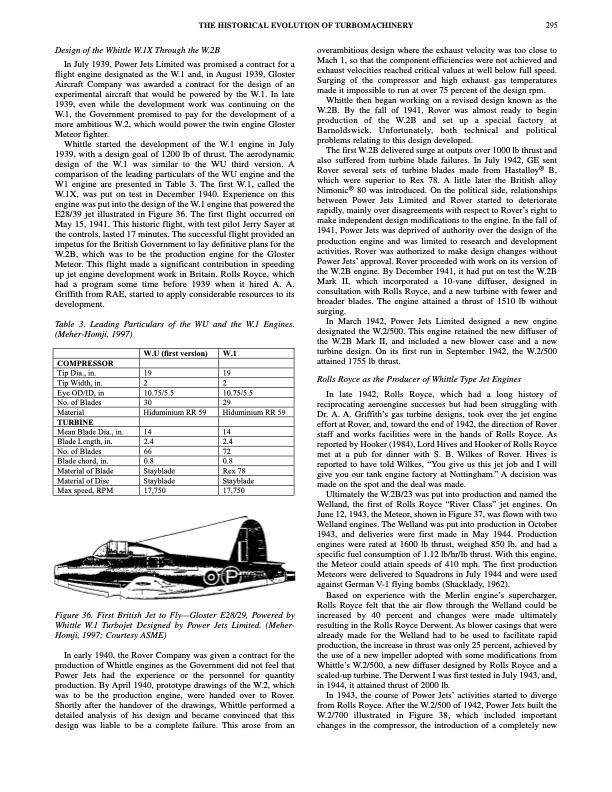

THE HISTORICAL EVOLUTION OF TURBOMACHINERY 295 Design of the Whittle W.1X Through the W.2B In July 1939, Power Jets Limited was promised a contract for a flight engine designated as the W.1 and, in August 1939, Gloster Aircraft Company was awarded a contract for the design of an experimental aircraft that would be powered by the W.1. In late 1939, even while the development work was continuing on the W.1, the Government promised to pay for the development of a more ambitious W.2, which would power the twin engine Gloster Meteor fighter. Whittle started the development of the W.1 engine in July 1939, with a design goal of 1200 lb of thrust. The aerodynamic design of the W.1 was similar to the WU third version. A comparison of the leading particulars of the WU engine and the W1 engine are presented in Table 3. The first W.1, called the W.1X, was put on test in December 1940. Experience on this engine was put into the design of the W.1 engine that powered the E28/39 jet illustrated in Figure 36. The first flight occurred on May 15, 1941. This historic flight, with test pilot Jerry Sayer at the controls, lasted 17 minutes. The successful flight provided an impetus for the British Government to lay definitive plans for the W.2B, which was to be the production engine for the Gloster Meteor. This flight made a significant contribution in speeding up jet engine development work in Britain. Rolls Royce, which had a program some time before 1939 when it hired A. A. Griffith from RAE, started to apply considerable resources to its development. Table 3. Leading Particulars of the WU and the W.1 Engines. (Meher-Homji, 1997) overambitious design where the exhaust velocity was too close to Mach 1, so that the component efficiencies were not achieved and exhaust velocities reached critical values at well below full speed. Surging of the compressor and high exhaust gas temperatures made it impossible to run at over 75 percent of the design rpm. Whittle then began working on a revised design known as the W.2B. By the fall of 1941, Rover was almost ready to begin production of the W.2B and set up a special factory at Barnoldswick. Unfortunately, both technical and political problems relating to this design developed. The first W.2B delivered surge at outputs over 1000 lb thrust and also suffered from turbine blade failures. In July 1942, GE sent Rover several sets of turbine blades made from Hastalloy® B, which were superior to Rex 78. A little later the British alloy Nimonic® 80 was introduced. On the political side, relationships between Power Jets Limited and Rover started to deteriorate rapidly, mainly over disagreements with respect to Rover’s right to make independent design modifications to the engine. In the fall of 1941, Power Jets was deprived of authority over the design of the production engine and was limited to research and development activities. Rover was authorized to make design changes without Power Jets’ approval. Rover proceeded with work on its version of the W.2B engine. By December 1941, it had put on test the W.2B Mark II, which incorporated a 10-vane diffuser, designed in consultation with Rolls Royce, and a new turbine with fewer and broader blades. The engine attained a thrust of 1510 lb without surging. In March 1942, Power Jets Limited designed a new engine designated the W.2/500. This engine retained the new diffuser of the W.2B Mark II, and included a new blower case and a new turbine design. On its first run in September 1942, the W.2/500 attained 1755 lb thrust. Rolls Royce as the Producer of Whittle Type Jet Engines In late 1942, Rolls Royce, which had a long history of reciprocating aeroengine successes but had been struggling with Dr. A. A. Griffith’s gas turbine designs, took over the jet engine effort at Rover, and, toward the end of 1942, the direction of Rover staff and works facilities were in the hands of Rolls Royce. As reported by Hooker (1984), Lord Hives and Hooker of Rolls Royce met at a pub for dinner with S. B. Wilkes of Rover. Hives is reported to have told Wilkes, “You give us this jet job and I will give you our tank engine factory at Nottingham.” A decision was made on the spot and the deal was made. Ultimately the W.2B/23 was put into production and named the Welland, the first of Rolls Royce “River Class” jet engines. On June 12, 1943, the Meteor, shown in Figure 37, was flown with two Welland engines. The Welland was put into production in October 1943, and deliveries were first made in May 1944. Production engines were rated at 1600 lb thrust, weighed 850 lb, and had a specific fuel consumption of 1.12 lb/hr/lb thrust. With this engine, the Meteor could attain speeds of 410 mph. The first production Meteors were delivered to Squadrons in July 1944 and were used against German V-1 flying bombs (Shacklady, 1962). Based on experience with the Merlin engine’s supercharger, Rolls Royce felt that the air flow through the Welland could be increased by 40 percent and changes were made ultimately resulting in the Rolls Royce Derwent. As blower casings that were already made for the Welland had to be used to facilitate rapid production, the increase in thrust was only 25 percent, achieved by the use of a new impeller adopted with some modifications from Whittle’s W.2/500, a new diffuser designed by Rolls Royce and a scaled-up turbine. The Derwent I was first tested in July 1943, and, in 1944, it attained thrust of 2000 lb. In 1943, the course of Power Jets’ activities started to diverge from Rolls Royce. After the W.2/500 of 1942, Power Jets built the W.2/700 illustrated in Figure 38, which included important changes in the compressor, the introduction of a completely new Figure 36. First British Jet to Fly—Gloster E28/29, Powered by Whittle W.1 Turbojet Designed by Power Jets Limited. (Meher- Homji, 1997; Courtesy ASME) In early 1940, the Rover Company was given a contract for the production of Whittle engines as the Government did not feel that Power Jets had the experience or the personnel for quantity production. By April 1940, prototype drawings of the W.2, which was to be the production engine, were handed over to Rover. Shortly after the handover of the drawings, Whittle performed a detailed analysis of his design and became convinced that this design was liable to be a complete failure. This arose from an COMPRESSOR Tip Dia., in. Tip Width, in. Eye OD/ID, in No. of Blades Material TURBINE Mean Blade Dia., in. Blade Length, in. No. of Blades Blade chord, in. Material of Blade Material of Disc Max speed, RPM W.U (first version) 19 2 10.75/5.5 30 Hiduminium RR 59 14 2.4 66 0.8 Stayblade Stayblade 17,750 W.1 19 2 10.75/5.5 29 Hiduminium RR 59 14 2.4 72 0.8 Rex 78 Stayblade 17,750PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |