PDF Publication Title:

Text from PDF Page: 018

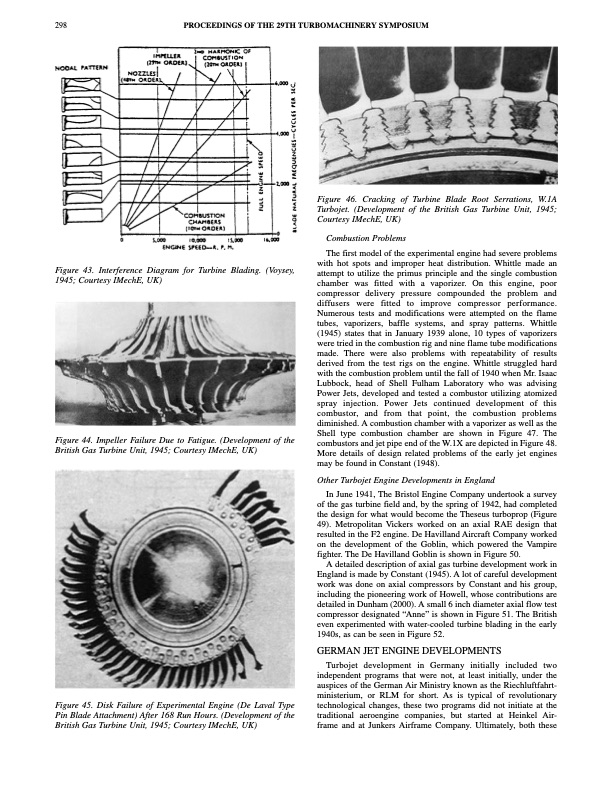

298 PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM Figure 43. Interference Diagram for Turbine Blading. (Voysey, 1945; Courtesy IMechE, UK) Figure 44. Impeller Failure Due to Fatigue. (Development of the British Gas Turbine Unit, 1945; Courtesy IMechE, UK) Figure 45. Disk Failure of Experimental Engine (De Laval Type Pin Blade Attachment) After 168 Run Hours. (Development of the British Gas Turbine Unit, 1945; Courtesy IMechE, UK) Figure 46. Cracking of Turbine Blade Root Serrations, W.1A Turbojet. (Development of the British Gas Turbine Unit, 1945; Courtesy IMechE, UK) Combustion Problems The first model of the experimental engine had severe problems with hot spots and improper heat distribution. Whittle made an attempt to utilize the primus principle and the single combustion chamber was fitted with a vaporizer. On this engine, poor compressor delivery pressure compounded the problem and diffusers were fitted to improve compressor performance. Numerous tests and modifications were attempted on the flame tubes, vaporizers, baffle systems, and spray patterns. Whittle (1945) states that in January 1939 alone, 10 types of vaporizers were tried in the combustion rig and nine flame tube modifications made. There were also problems with repeatability of results derived from the test rigs on the engine. Whittle struggled hard with the combustion problem until the fall of 1940 when Mr. Isaac Lubbock, head of Shell Fulham Laboratory who was advising Power Jets, developed and tested a combustor utilizing atomized spray injection. Power Jets continued development of this combustor, and from that point, the combustion problems diminished. A combustion chamber with a vaporizer as well as the Shell type combustion chamber are shown in Figure 47. The combustors and jet pipe end of the W.1X are depicted in Figure 48. More details of design related problems of the early jet engines may be found in Constant (1948). Other Turbojet Engine Developments in England In June 1941, The Bristol Engine Company undertook a survey of the gas turbine field and, by the spring of 1942, had completed the design for what would become the Theseus turboprop (Figure 49). Metropolitan Vickers worked on an axial RAE design that resulted in the F2 engine. De Havilland Aircraft Company worked on the development of the Goblin, which powered the Vampire fighter. The De Havilland Goblin is shown in Figure 50. A detailed description of axial gas turbine development work in England is made by Constant (1945). A lot of careful development work was done on axial compressors by Constant and his group, including the pioneering work of Howell, whose contributions are detailed in Dunham (2000). A small 6 inch diameter axial flow test compressor designated “Anne” is shown in Figure 51. The British even experimented with water-cooled turbine blading in the early 1940s, as can be seen in Figure 52. GERMAN JET ENGINE DEVELOPMENTS Turbojet development in Germany initially included two independent programs that were not, at least initially, under the auspices of the German Air Ministry known as the Riechluftfahrt- ministerium, or RLM for short. As is typical of revolutionary technological changes, these two programs did not initiate at the traditional aeroengine companies, but started at Heinkel Air- frame and at Junkers Airframe Company. Ultimately, both thesePDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |