PDF Publication Title:

Text from PDF Page: 020

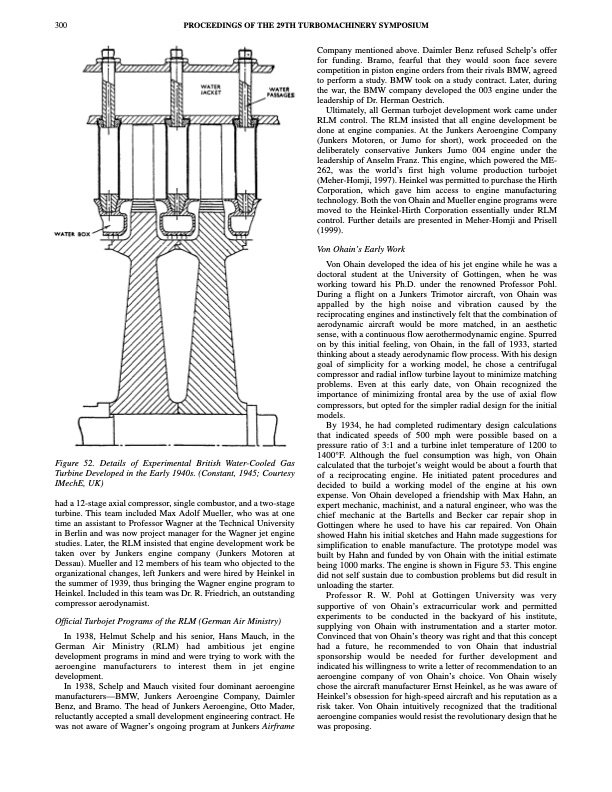

300 PROCEEDINGS OF THE 29TH TURBOMACHINERY SYMPOSIUM Figure 52. Details of Experimental British Water-Cooled Gas Turbine Developed in the Early 1940s. (Constant, 1945; Courtesy IMechE, UK) had a 12-stage axial compressor, single combustor, and a two-stage turbine. This team included Max Adolf Mueller, who was at one time an assistant to Professor Wagner at the Technical University in Berlin and was now project manager for the Wagner jet engine studies. Later, the RLM insisted that engine development work be taken over by Junkers engine company (Junkers Motoren at Dessau). Mueller and 12 members of his team who objected to the organizational changes, left Junkers and were hired by Heinkel in the summer of 1939, thus bringing the Wagner engine program to Heinkel. Included in this team was Dr. R. Friedrich, an outstanding compressor aerodynamist. Official Turbojet Programs of the RLM (German Air Ministry) In 1938, Helmut Schelp and his senior, Hans Mauch, in the German Air Ministry (RLM) had ambitious jet engine development programs in mind and were trying to work with the aeroengine manufacturers to interest them in jet engine development. In 1938, Schelp and Mauch visited four dominant aeroengine manufacturers—BMW, Junkers Aeroengine Company, Daimler Benz, and Bramo. The head of Junkers Aeroengine, Otto Mader, reluctantly accepted a small development engineering contract. He was not aware of Wagner’s ongoing program at Junkers Airframe Company mentioned above. Daimler Benz refused Schelp’s offer for funding. Bramo, fearful that they would soon face severe competition in piston engine orders from their rivals BMW, agreed to perform a study. BMW took on a study contract. Later, during the war, the BMW company developed the 003 engine under the leadership of Dr. Herman Oestrich. Ultimately, all German turbojet development work came under RLM control. The RLM insisted that all engine development be done at engine companies. At the Junkers Aeroengine Company (Junkers Motoren, or Jumo for short), work proceeded on the deliberately conservative Junkers Jumo 004 engine under the leadership of Anselm Franz. This engine, which powered the ME- 262, was the world’s first high volume production turbojet (Meher-Homji, 1997). Heinkel was permitted to purchase the Hirth Corporation, which gave him access to engine manufacturing technology. Both the von Ohain and Mueller engine programs were moved to the Heinkel-Hirth Corporation essentially under RLM control. Further details are presented in Meher-Homji and Prisell (1999). Von Ohain’s Early Work Von Ohain developed the idea of his jet engine while he was a doctoral student at the University of Gottingen, when he was working toward his Ph.D. under the renowned Professor Pohl. During a flight on a Junkers Trimotor aircraft, von Ohain was appalled by the high noise and vibration caused by the reciprocating engines and instinctively felt that the combination of aerodynamic aircraft would be more matched, in an aesthetic sense, with a continuous flow aerothermodynamic engine. Spurred on by this initial feeling, von Ohain, in the fall of 1933, started thinking about a steady aerodynamic flow process. With his design goal of simplicity for a working model, he chose a centrifugal compressor and radial inflow turbine layout to minimize matching problems. Even at this early date, von Ohain recognized the importance of minimizing frontal area by the use of axial flow compressors, but opted for the simpler radial design for the initial models. By 1934, he had completed rudimentary design calculations that indicated speeds of 500 mph were possible based on a pressure ratio of 3:1 and a turbine inlet temperature of 1200 to 1400°F. Although the fuel consumption was high, von Ohain calculated that the turbojet’s weight would be about a fourth that of a reciprocating engine. He initiated patent procedures and decided to build a working model of the engine at his own expense. Von Ohain developed a friendship with Max Hahn, an expert mechanic, machinist, and a natural engineer, who was the chief mechanic at the Bartells and Becker car repair shop in Gottingen where he used to have his car repaired. Von Ohain showed Hahn his initial sketches and Hahn made suggestions for simplification to enable manufacture. The prototype model was built by Hahn and funded by von Ohain with the initial estimate being 1000 marks. The engine is shown in Figure 53. This engine did not self sustain due to combustion problems but did result in unloading the starter. Professor R. W. Pohl at Gottingen University was very supportive of von Ohain’s extracurricular work and permitted experiments to be conducted in the backyard of his institute, supplying von Ohain with instrumentation and a starter motor. Convinced that von Ohain’s theory was right and that this concept had a future, he recommended to von Ohain that industrial sponsorship would be needed for further development and indicated his willingness to write a letter of recommendation to an aeroengine company of von Ohain’s choice. Von Ohain wisely chose the aircraft manufacturer Ernst Heinkel, as he was aware of Heinkel’s obsession for high-speed aircraft and his reputation as a risk taker. Von Ohain intuitively recognized that the traditional aeroengine companies would resist the revolutionary design that he was proposing.PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |