PDF Publication Title:

Text from PDF Page: 023

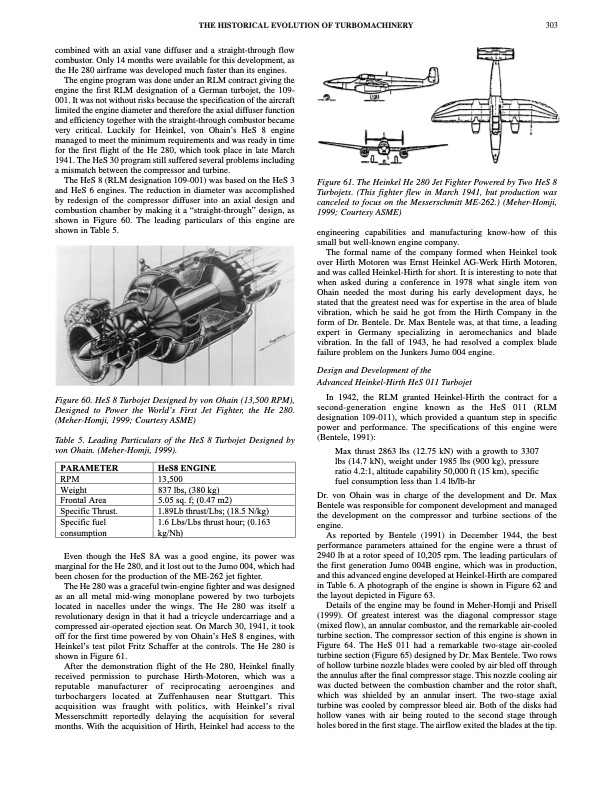

THE HISTORICAL EVOLUTION OF TURBOMACHINERY 303 PARAMETER RPM Weight Frontal Area Specific Thrust. Specific fuel consumption HeS8 ENGINE 13,500 837 lbs, (380 kg) 5.05 sq. f; (0.47 m2) 1.89Lb thrust/Lbs; (18.5 N/kg) 1.6 Lbs/Lbs thrust hour; (0.163 kg/Nh) combined with an axial vane diffuser and a straight-through flow combustor. Only 14 months were available for this development, as the He 280 airframe was developed much faster than its engines. The engine program was done under an RLM contract giving the engine the first RLM designation of a German turbojet, the 109- 001. It was not without risks because the specification of the aircraft limited the engine diameter and therefore the axial diffuser function and efficiency together with the straight-through combustor became very critical. Luckily for Heinkel, von Ohain’s HeS 8 engine managed to meet the minimum requirements and was ready in time for the first flight of the He 280, which took place in late March 1941. The HeS 30 program still suffered several problems including a mismatch between the compressor and turbine. The HeS 8 (RLM designation 109-001) was based on the HeS 3 and HeS 6 engines. The reduction in diameter was accomplished by redesign of the compressor diffuser into an axial design and combustion chamber by making it a “straight-through” design, as shown in Figure 60. The leading particulars of this engine are shown in Table 5. Figure 60. HeS 8 Turbojet Designed by von Ohain (13,500 RPM), Designed to Power the World’s First Jet Fighter, the He 280. (Meher-Homji, 1999; Courtesy ASME) Table 5. Leading Particulars of the HeS 8 Turbojet Designed by von Ohain. (Meher-Homji, 1999). Even though the HeS 8A was a good engine, its power was marginal for the He 280, and it lost out to the Jumo 004, which had been chosen for the production of the ME-262 jet fighter. The He 280 was a graceful twin-engine fighter and was designed as an all metal mid-wing monoplane powered by two turbojets located in nacelles under the wings. The He 280 was itself a revolutionary design in that it had a tricycle undercarriage and a compressed air-operated ejection seat. On March 30, 1941, it took off for the first time powered by von Ohain’s HeS 8 engines, with Heinkel’s test pilot Fritz Schaffer at the controls. The He 280 is shown in Figure 61. After the demonstration flight of the He 280, Heinkel finally received permission to purchase Hirth-Motoren, which was a reputable manufacturer of reciprocating aeroengines and turbochargers located at Zuffenhausen near Stuttgart. This acquisition was fraught with politics, with Heinkel’s rival Messerschmitt reportedly delaying the acquisition for several months. With the acquisition of Hirth, Heinkel had access to the Figure 61. The Heinkel He 280 Jet Fighter Powered by Two HeS 8 Turbojets. (This fighter flew in March 1941, but production was canceled to focus on the Messerschmitt ME-262.) (Meher-Homji, 1999; Courtesy ASME) engineering capabilities and manufacturing know-how of this small but well-known engine company. The formal name of the company formed when Heinkel took over Hirth Motoren was Ernst Heinkel AG-Werk Hirth Motoren, and was called Heinkel-Hirth for short. It is interesting to note that when asked during a conference in 1978 what single item von Ohain needed the most during his early development days, he stated that the greatest need was for expertise in the area of blade vibration, which he said he got from the Hirth Company in the form of Dr. Bentele. Dr. Max Bentele was, at that time, a leading expert in Germany specializing in aeromechanics and blade vibration. In the fall of 1943, he had resolved a complex blade failure problem on the Junkers Jumo 004 engine. Design and Development of the Advanced Heinkel-Hirth HeS 011 Turbojet In 1942, the RLM granted Heinkel-Hirth the contract for a second-generation engine known as the HeS 011 (RLM designation 109-011), which provided a quantum step in specific power and performance. The specifications of this engine were (Bentele, 1991): Max thrust 2863 lbs (12.75 kN) with a growth to 3307 lbs (14.7 kN), weight under 1985 lbs (900 kg), pressure ratio 4.2:1, altitude capability 50,000 ft (15 km), specific fuel consumption less than 1.4 lb/lb-hr Dr. von Ohain was in charge of the development and Dr. Max Bentele was responsible for component development and managed the development on the compressor and turbine sections of the engine. As reported by Bentele (1991) in December 1944, the best performance parameters attained for the engine were a thrust of 2940 lb at a rotor speed of 10,205 rpm. The leading particulars of the first generation Jumo 004B engine, which was in production, and this advanced engine developed at Heinkel-Hirth are compared in Table 6. A photograph of the engine is shown in Figure 62 and the layout depicted in Figure 63. Details of the engine may be found in Meher-Homji and Prisell (1999). Of greatest interest was the diagonal compressor stage (mixed flow), an annular combustor, and the remarkable air-cooled turbine section. The compressor section of this engine is shown in Figure 64. The HeS 011 had a remarkable two-stage air-cooled turbine section (Figure 65) designed by Dr. Max Bentele. Two rows of hollow turbine nozzle blades were cooled by air bled off through the annulus after the final compressor stage. This nozzle cooling air was ducted between the combustion chamber and the rotor shaft, which was shielded by an annular insert. The two-stage axial turbine was cooled by compressor bleed air. Both of the disks had hollow vanes with air being routed to the second stage through holes bored in the first stage. The airflow exited the blades at the tip.PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |