PDF Publication Title:

Text from PDF Page: 027

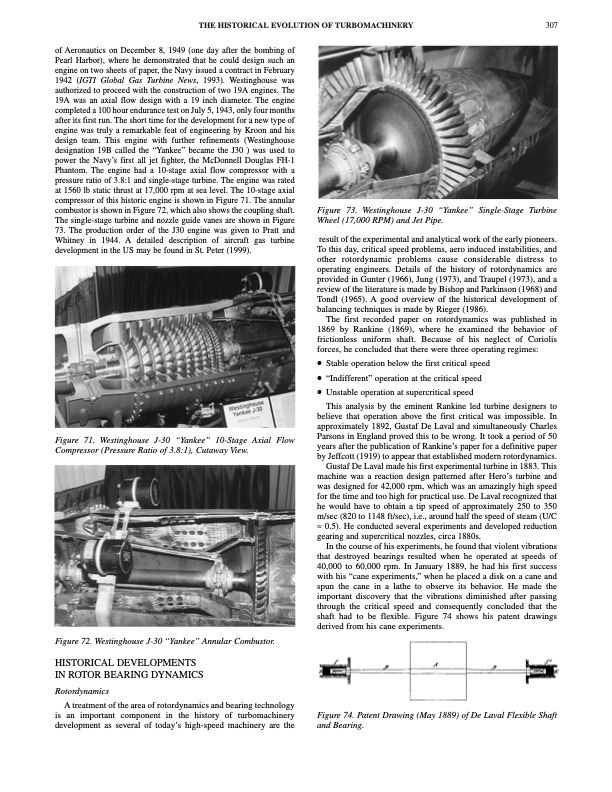

THE HISTORICAL EVOLUTION OF TURBOMACHINERY 307 of Aeronautics on December 8, 1949 (one day after the bombing of Pearl Harbor), where he demonstrated that he could design such an engine on two sheets of paper, the Navy issued a contract in February 1942 (IGTI Global Gas Turbine News, 1993). Westinghouse was authorized to proceed with the construction of two 19A engines. The 19A was an axial flow design with a 19 inch diameter. The engine completed a 100 hour endurance test on July 5, 1943, only four months after its first run. The short time for the development for a new type of engine was truly a remarkable feat of engineering by Kroon and his design team. This engine with further refinements (Westinghouse designation 19B called the “Yankee” became the J30 ) was used to power the Navy’s first all jet fighter, the McDonnell Douglas FH-1 Phantom. The engine had a 10-stage axial flow compressor with a pressure ratio of 3.8:1 and single-stage turbine. The engine was rated at 1560 lb static thrust at 17,000 rpm at sea level. The 10-stage axial compressor of this historic engine is shown in Figure 71. The annular combustor is shown in Figure 72, which also shows the coupling shaft. The single-stage turbine and nozzle guide vanes are shown in Figure 73. The production order of the J30 engine was given to Pratt and Whitney in 1944. A detailed description of aircraft gas turbine development in the US may be found in St. Peter (1999). Figure 71. Westinghouse J-30 “Yankee” 10-Stage Axial Flow Compressor (Pressure Ratio of 3.8:1), Cutaway View. Figure 72. Westinghouse J-30 “Yankee” Annular Combustor. HISTORICAL DEVELOPMENTS IN ROTOR BEARING DYNAMICS Rotordynamics A treatment of the area of rotordynamics and bearing technology is an important component in the history of turbomachinery development as several of today’s high-speed machinery are the Figure 73. Westinghouse J-30 “Yankee” Single-Stage Turbine Wheel (17,000 RPM) and Jet Pipe. result of the experimental and analytical work of the early pioneers. To this day, critical speed problems, aero induced instabilities, and other rotordynamic problems cause considerable distress to operating engineers. Details of the history of rotordynamics are provided in Gunter (1966), Jung (1973), and Traupel (1973), and a review of the literature is made by Bishop and Parkinson (1968) and Tondl (1965). A good overview of the historical development of balancing techniques is made by Rieger (1986). The first recorded paper on rotordynamics was published in 1869 by Rankine (1869), where he examined the behavior of frictionless uniform shaft. Because of his neglect of Coriolis forces, he concluded that there were three operating regimes: • Stable operation below the first critical speed • “Indifferent” operation at the critical speed • Unstable operation at supercritical speed This analysis by the eminent Rankine led turbine designers to believe that operation above the first critical was impossible. In approximately 1892, Gustaf De Laval and simultaneously Charles Parsons in England proved this to be wrong. It took a period of 50 years after the publication of Rankine’s paper for a definitive paper by Jeffcott (1919) to appear that established modern rotordynamics. Gustaf De Laval made his first experimental turbine in 1883. This machine was a reaction design patterned after Hero’s turbine and was designed for 42,000 rpm, which was an amazingly high speed for the time and too high for practical use. De Laval recognized that he would have to obtain a tip speed of approximately 250 to 350 m/sec (820 to 1148 ft/sec), i.e., around half the speed of steam (U/C ≈ 0.5). He conducted several experiments and developed reduction gearing and supercritical nozzles, circa 1880s. In the course of his experiments, he found that violent vibrations that destroyed bearings resulted when he operated at speeds of 40,000 to 60,000 rpm. In January 1889, he had his first success with his “cane experiments,” when he placed a disk on a cane and spun the cane in a lathe to observe its behavior. He made the important discovery that the vibrations diminished after passing through the critical speed and consequently concluded that the shaft had to be flexible. Figure 74 shows his patent drawings derived from his cane experiments. Figure 74. Patent Drawing (May 1889) of De Laval Flexible Shaft and Bearing.PDF Image | THE HISTORICAL EVOLUTION OF TURBOMACHINERY

PDF Search Title:

THE HISTORICAL EVOLUTION OF TURBOMACHINERYOriginal File Name Searched:

t29pg281.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |