PDF Publication Title:

Text from PDF Page: 014

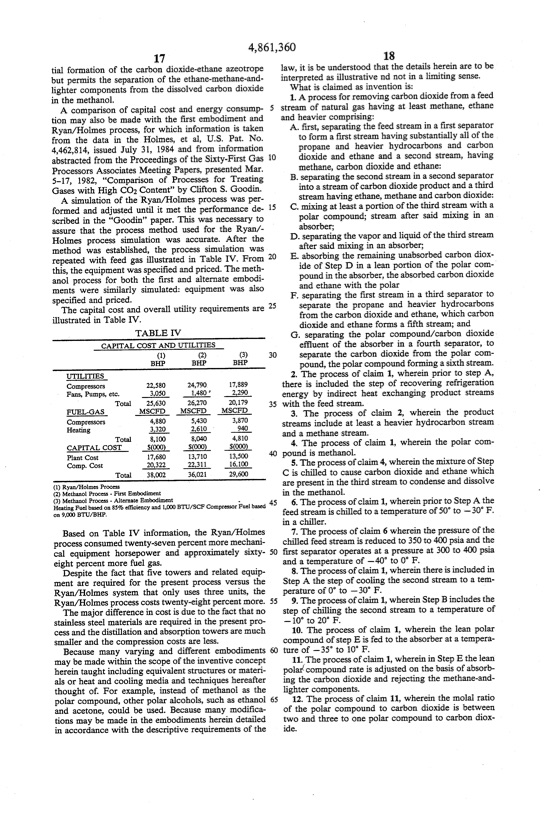

17 tial formation of the carbon dioxide-ethane azeotrope but permits the separation of the ethane-methane-and lighter components from the dissolved carbon dioxide 18 law, itisbe understood that the details herein are to be interpreted as illustrative nd not in a limiting sense. What is claimed as invention is: 1.A processforremovingcarbondioxidefromafeed tion may also be made with the ?rst embodiment and Ryan/Holmes process, for which information is taken from the data in the Holmes, et al, US. Pat. No. 4,462,814, issued July 31, 1984 and from information abstracted from the Proceedings of the Sixty-First Gas Processors Associates Meeting Papers, presented Mar. 5-17, 1982, “Comparison of Processes for Treating Gases with High CO2 Content” by Clifton S. Goodin. A simulationoftheRyan/Holmesprocesswasper formedandadjusteduntilitmettheperformancede 15 scribed in the “Goodin” paper. This was necessary to assure that the process method used for the Ryan/ Holmes process simulation was accurate. After the method was established, the process simulation was repeatedwithfeedgasillustratedinTableIV.From 20 this,the equipment was speci?ed and priced. The meth anol process for both the ?rst and alternate embodi ments were similarly simulated: equipment was also speci?ed and priced. The capital cost and overall utility requirements are 25 illustrated in Table IV. TABLE IV CAPITALcos'rANDUTILITIES and heavier comprising: A. ?rst, separating the feed stream in a ?rst separator to form a ?rst stream having substantially all of the propane and heavier hydrocarbons and carbon dioxide and ethane and a second stream, having methane, carbon dioxide and ethane: B. separating the second stream in a second separator into a stream of carbon dioxide product and a third streamhavingethane,methaneandcarbondioxide: C.mixingatleastaportionofthethirdstreamwitha polar compound; stream after said mixing in an absorber; D. separating the vapor and liquid of the third stream after said mixing in an absorber; E.absorbingtheremainingunabsorbedcarbondiox ideofStepD inaleanportionofthepolarcom? poundintheabsorber,theabsorbedcarbondioxide and ethane with the polar F. separating the ?rst stream in a third separator to separate the propane and heavier hydrocarbons from the carbon dioxide and ethane, which carbon dioxide and ethane forms a ?fth stream; and G. separating the polar compound/carbon dioxide ef?uent of the absorber in a fourth separator, to separate the carbon dioxide from the polar com pound,thepolarcompoundformingasixthstream. 2. The process of claim 1, wherein prior to step A, there is included the step of recovering refrigeration energy by indirect heat exchanging product streams with the feed stream. 3. The process of claim 2, wherein the product streams include at least a heavier hydrocarbon stream and a methane stream. 4. The process of claim 1, wherein the polar com pound ismethanol. 5.The processofclaim4,whereinthemixtureofStep C ischilledtocausecarbondioxideandethanewhich are present in the third stream to condense and dissolve in the methanol. 6.Theprocessofclaim1,whereinpriortoStepA the feed stream is chilled to a temperature of 50° to — 30° F. in a chiller. UTILITIES Compressors Fans, Pumps, etc. 24,790 17,889 1,480 ' 2,290 26,270 20,179 FUEL-GAS Compressors Heating MSCFD MSCFD MSCFD Total (1) BHP 22,580 3,050 25,630 (2) (3) 30 BHP BHP 4,861,360 in the methanol. A comparisonofcapitalcostandenergyconsump 5 streamofnaturalgashavingatleastmethane,ethane CAPITAL COST PlantCost Comp. Cost $(OO0) 8(000) 17,680 13,710 20,322 22,311 4,880 5,430 3,320 2,610 ' 3,870 940 4,810 $(000) 13,500 16,100 Total 8,100 8,040 Total 38,002 36,021 29,600 (1)Ryan/HolmesProcess (2) Methanol Process ~ First Embodiment (3) Methanol Process -Alternate Embodiment , HeatingFuelbasedon 85% efficiencyand 1,000BTU/SCF CompressorFuelbased on 9,000 BTU/BHP. 45 7. The process of claim 6 wherein the pressure of the chilled feed stream isreduced to 350 to 400 psia and the calequipmenthorsepowerandapproximatelysixty50 ?rstseparatoroperatesatapressureat300to400psia Based on Table IV information, the Ryan/Holmes process consumed twenty-seven percent more mechani eight percent more fuel gas. Despite the fact that ?ve towers and related equip ment are required for the present process versus the Ryan/Holmes system that only uses three units, the Ryan/Holmesprocesscoststwenty-eightpercentmore. 55 The major differenceincostisdue tothefactthatno stainless steel materials are required in the present pro cess and the distillation and absorption towers are much smaller and the compression costs are less. and a temperature of —40° to 0° F. 8.The processofclaim1,whereinthereisincludedin StepA thestepofcoolingthesecondstreamtoatem perature of 0° to —30° F. 9.Theprocessofclaim1,whereinStepBincludesthe step of chilling the second stream to a temperature of — 10° to 20° F. 10. The process of claim 1, wherein the lean polar compound ofstepE isfedtotheabsorberatatempera Because many varying and different embodiments 60 ture of —35° to 10° F. may bemade withinthescopeoftheinventiveconcept hereintaughtincludingequivalentstructuresormateri als or heat and cooling media and techniques hereafter thought of. For example, instead of methanol as the polar compound, other polar alcohols, such as ethanol 65 and acetone, could be used. Because many modi?ca tions may be made in the embodiments herein detailed in accordance with the descriptive requirements of the 11.‘Theprocessofclaim1,whereininStepE thelean polaricompound rateisadjustedon thebasisofabsorb ing the carbon dioxide and rejecting the methane-and lightercomponents. 12. The process of claim 11, wherein the molal ratio of the polar compound to carbon dioxide is between two and three to one polar compound to carbon diox ide.PDF Image | CARBON DIOXIDE ABSORPTION METHANOL PROCESS

PDF Search Title:

CARBON DIOXIDE ABSORPTION METHANOL PROCESSOriginal File Name Searched:

US4861360.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |