PDF Publication Title:

Text from PDF Page: 006

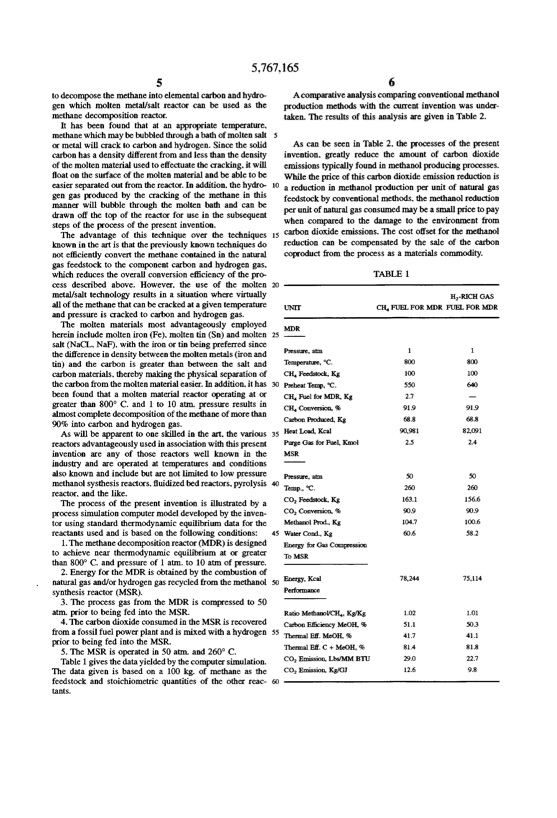

5,767,165 56 todecomposethemethaneintoelementalcarbonandhydro Acomparativeanalysiscomparingconventionalmethanol gen which molten metal/salt reactor can be used as the methane decomposition reactor. It has been found that at an appropriate temperature. methanewhichmay bebubbledthroughabathofmoltensalt or metal will crack to carbon and hydrogen. Since the solid carbon has a density different from and less than the density ofthemoltenmaterialusedtoeffectuatethecracking.itwill ?oat on the surface of the molten material and be able to be easierseparatedoutfromthereactor.Inaddition.thehydro gen gas produced by the cracking of the methane in this manner will bubble through the molten bath and can be drawn off the top of the reactor for use in the subsequent steps of the process of the present invention. The advantage of this technique over the techniques known in the art is that the previously known techniques do not e?iciently convert the methane contained in the natural gas feedstock to the component carbon and hydrogen gas. which reduces the overall conversion efficiency of the pro cess described above. However. the use of the molten metal/salt technology results in a situation where virtually all of the methane that can be cracked at a given temperature and pressure is cracked to carbon and hydrogen gas. production methods with the current invention was under taken. The results of this analysis are given in Table 2. As can be seen in Table 2. the processes of the present invention. greatly reduce the amount of carbon dioxide emissionstypicallyfoundinmethanolproducingprocesses. While the price of this carbon dioxide emission reduction is a reduction in methanol production per unit of natural gas feedstock by conventional methods. the methanol reduction perunitofnaturalgasconsumedmay beasmallpricetopay when compared to the damage to the environment from carbon dioxide emissions. The cost offset for the methanol reduction can be compensated by the sale of the carbon coproduct from the process as a materials commodity. The molten materials most advantageously employed hereinincludemolteniron(Fe).moltentin(Sn)andmolten salt (NaCL. NaF). with the iron or tin being preferred since thedi?’erenceindensitybetweenthemoltenmetals(ironand tin) and the carbon is greater than between the salt and carbonmaterials.therebymakingthephysicalseparationof CH‘Feedstock,Kg thecarbonfromthemoltenmaterialeasier.Inaddition.ithas been found that a molten material reactor operating at or greater than 800° C. and 1 to 10 atm. pressure results in almostcomplete decomposition ofthemethane ofmore than 90% into carbon and hydrogen gas. Aswillbeapparenttooneskilledintheart.thevarious reactorsadvantageouslyusedinassociationwiththispresent invention are any of those reactors well known in the industry and are operated at temperatures and conditions also known and include but are not limited to low pressure methanolsysthesisreactors.?uidizedbedreactors.pyrolysis reactor. and the like. The process of the present invention is illustrated by a processsimulationcomputermodeldevelopedbytheinven tor using standard thermodynamic equilibrium data for the reactants used and is based on the following conditions: 1.The methane decompositionreactor(MDR) isdesigned to achieve near thermodynamic equilibrium at or greater than 800° C. and pressure of l atrn. to 10 atrn of pressure. 2.EnergyfortheMDR isobtainedbythecombustionof naturalgasand/orhydrogengasrecycledfromthemethanol synthesisreactor(MSR). 3.TheprocessgasfromtheMDR iscompressedto50 atrn. prior to being fed into the MSR. 4.ThecarbondioxideconsumedintheMSR isrecovered from a fossil fuel power plant and is mixed with a hydrogen prior to being fed into the MSR. 5.TheMSR isoperatedin50atm.and260°C. Table1givesthedatayieldedbythecomputersimulation. The data given is based on a 100 kg. of methane as the feedstock and stoichiometric quantities of the other reac tants. 30 PreheatTemp. “C. CH4 Fuel forMDR, Kg Cl-l4Conversion.% 91.9 919 CarbonProduced1Kg 68.8 68.8 20 TABLE 1 H2-RICH GAS CI-LFUELFOR MDR FUELFOR MDR 1 1 800 800 100 100 550 640 2.7 — 25 UNIT M'DR Pressure, atm Temperature. °C. 35 HeatLoad.Kcal Pm-geGas forFuel,Kmol MSR Pressure. atm Temp, °C. C0, Feedstock,Kg CD, Conversion. % Methanol Prod. Kg Water ConcL, Kg Energy forGas Compression T0MSR 50 Energy.Kcal Performance RatioMethanol/CH4, Kg/Kg CarbonEl?ciencyMeOH, % 55 ThermalEff.MeOH. % Thermal BE. C + MeOH, % C0; Emission1Lbs/MM BTU co2 Emission, Kg/GJ 90,981 82,091 2.5 2.4 50 50 260 260 163.1 156.6 90.9 90.9 104.7 100.6 60.6 58.2 78,244 75.114 1.02 1.01 51.1 50.3 41.7 41.1 81.4 81.8 29.0 22.7 12.6 9.8PDF Image | CONVERTING NATURAL GAS AND CARBON DIOXIDE TO METHANOL

PDF Search Title:

CONVERTING NATURAL GAS AND CARBON DIOXIDE TO METHANOLOriginal File Name Searched:

US5767165.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |