PDF Publication Title:

Text from PDF Page: 006

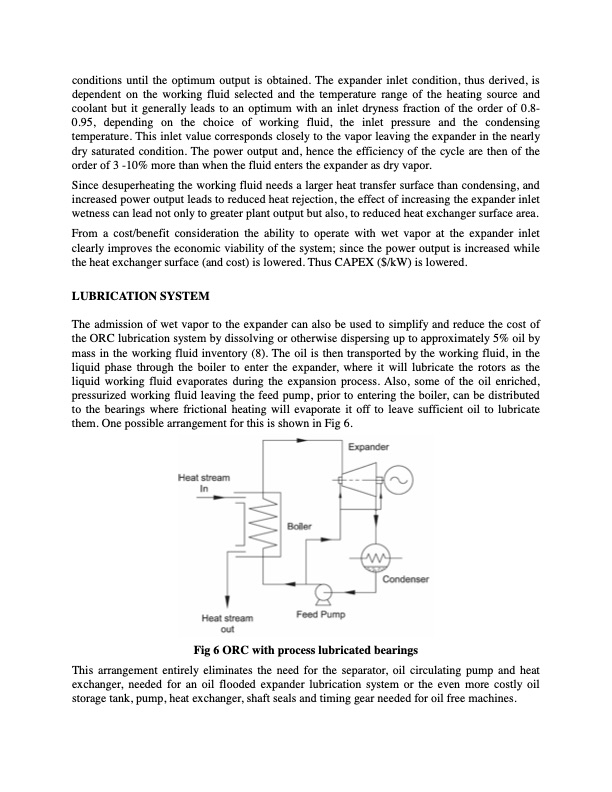

conditions until the optimum output is obtained. The expander inlet condition, thus derived, is dependent on the working fluid selected and the temperature range of the heating source and coolant but it generally leads to an optimum with an inlet dryness fraction of the order of 0.8- 0.95, depending on the choice of working fluid, the inlet pressure and the condensing temperature. This inlet value corresponds closely to the vapor leaving the expander in the nearly dry saturated condition. The power output and, hence the efficiency of the cycle are then of the order of 3 -10% more than when the fluid enters the expander as dry vapor. Since desuperheating the working fluid needs a larger heat transfer surface than condensing, and increased power output leads to reduced heat rejection, the effect of increasing the expander inlet wetness can lead not only to greater plant output but also, to reduced heat exchanger surface area. From a cost/benefit consideration the ability to operate with wet vapor at the expander inlet clearly improves the economic viability of the system; since the power output is increased while the heat exchanger surface (and cost) is lowered. Thus CAPEX ($/kW) is lowered. LUBRICATION SYSTEM The admission of wet vapor to the expander can also be used to simplify and reduce the cost of the ORC lubrication system by dissolving or otherwise dispersing up to approximately 5% oil by mass in the working fluid inventory (8). The oil is then transported by the working fluid, in the liquid phase through the boiler to enter the expander, where it will lubricate the rotors as the liquid working fluid evaporates during the expansion process. Also, some of the oil enriched, pressurized working fluid leaving the feed pump, prior to entering the boiler, can be distributed to the bearings where frictional heating will evaporate it off to leave sufficient oil to lubricate them. One possible arrangement for this is shown in Fig 6. Fig 6 ORC with process lubricated bearings This arrangement entirely eliminates the need for the separator, oil circulating pump and heat exchanger, needed for an oil flooded expander lubrication system or the even more costly oil storage tank, pump, heat exchanger, shaft seals and timing gear needed for oil free machines.PDF Image | COST EFFECTIVE SMALL SCALE ORC SYSTEMS

PDF Search Title:

COST EFFECTIVE SMALL SCALE ORC SYSTEMSOriginal File Name Searched:

Twin_Screw_Compressors.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |