PDF Publication Title:

Text from PDF Page: 012

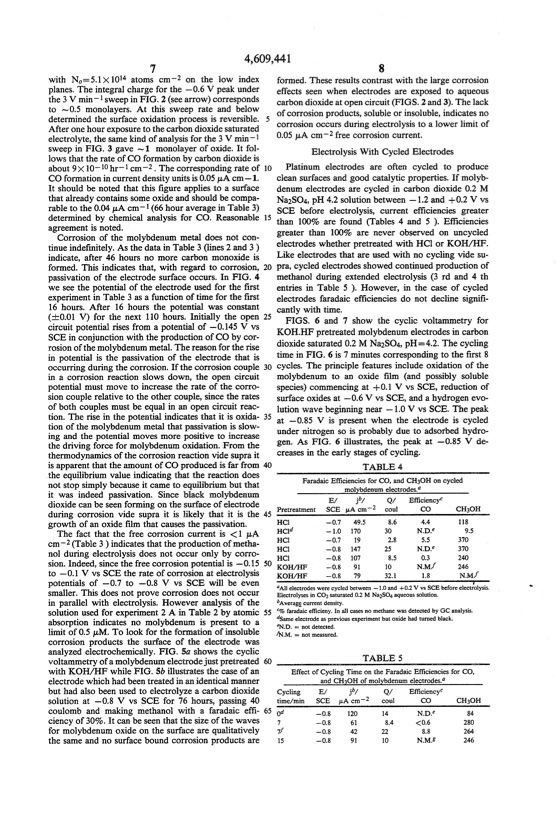

4,609,441 78 with No=5.lX 1014 atoms cm-2 on the low index planes.Theintegralchargeforthe—0.6V peakunder the3V min‘1sweepinFIG.2(seearrow)corresponds to ~05 monolayers. At this sweep rate and below determined the surface oxidation process is reversible. After one hour exposure to the carbon dioxide saturated electrolyte,thesamekindofanalysisforthe3V min—1 sweepinFIG.3gave~1 monolayerofoxide.Itfol lowsthattherateofCO formationbycarbondioxideis about 9X10’1O hr"l crn-2 .The corresponding rate of 10 CO formationincurrentdensityunitsis0.05uA cm- 1. It should be noted that this ?gure applies to a surface that already contains some oxide and should be compa rabletothe0.04uA cm"1(66houraverageinTable3) determined by chemical analysis for CO. Reasonable agreement isnoted. formed.Theseresultscontrastwiththelargecorrosion effects seen when electrodes are exposed to aqueous carbon dioxide at open circuit (FIGS. 2 and 3). The lack of corrosion products, soluble or insoluble, indicates no corrosion occurs during electrolysis to a lower limit of 0.05 ;:.A cm-2 free corrosion current. Electrolysis With Cycled Electrodes Platinum electrodes are often cycled to produce cleansurfacesandgoodcatalyticproperties.Ifmolyb denum electrodes are cycled in carbon dioxide 0.2 M Na2SO4,pH4.2solutionbetween—1.2and+0.2V vs SCE before electrolysis, current ef?ciencies greater than 100% are found (Tables 4 and 5 ). Efficiencies greater than 100% are never observed on uncycled electrodes whether pretreated with HCl or KOH/HF. Like electrodes that are used with no cycling vide su= Corrosion of the molybdenum metal does not con tinue inde?nitely. As the data in Table 3 (lines 2 and 3 ) indicate, after 46 hours no more carbon monoxide is formed.Thisindicatesthat,withregardtocorrosion,20 pra,cycledelectrodesshowedcontinuedproductionof passivation of the electrode surface occurs. In FIG. 4 we see the potential of the electrode used for the ?rst experiment in Table 3 as a function of time for the ?rst 16 hours. After 16 hours the potential was constant (i001 V) for the next 110 hours. Initially the open 25 circuitpotentialrisesfromapotentialof—0.l45V vs SCE inconjunctionwiththeproductionofCO bycor rosionofthemolybdenum metal.The reasonfortherise in potential is the passivation of the electrode that is occurringduringthecorrosion.Ifthecorrosioncouple30 cycles.Theprinciplefeaturesincludeoxidationofthe molybdenum to an oxide ?lm (and possibly soluble species) commencing at +0.1 V vs SCE, reduction of surfaceoxidesat—0.6V vsSCE,andahydrogenevo lutionwavebeginningnear—1.0V vsSCE.Thepeak in a corrosion reaction slows down, the open circuit potential must move to increase the rate of the corro sion couple relative to the other couple, since the rates of both couples must be equal in an open circuit reac tion.Theriseinthepotentialindicatesthatitisoxida 35 at-0.85V ispresentwhentheelectrodeiscycled tion of the molybdenum metal that passivation is slow= ing and the potential moves more positive to increase the driving force for molybdenum oxidation. From the thermodynamics of the corrosion reaction vide supra it isapparentthattheamountofCO producedisfarfrom .the equilibrium value indicating that the reaction does not stop simply because itcame to equilibrium but that it was indeed passivation. Since black molybdenum dioxide can be seen forming on the surface of electrode during corrosion vide supra it is likely that it is the 45 growth of an oxide ?lm that causes the passivation. Thefactthatthefreecorrosioncurrentis<1 uA cin-2(Table3)indicatesthattheproductionofmetha nol during electrolysis does not occur only by corro sion. Indeed, since the free corrosion potential is —O. 15 to—O.lV vsSCEtherateofcorrosionatelectrolysis potentials of —O.7 to —0.8 V vs SCE will be even smaller. This does not prove corrosion does not occur under nitrogen so is probably due to adsorbed hydro gen. As FIG. 6 illustrates, the peak at —0.85 V de creasesintheearlystagesofcycling. TABLE 4 FaradaicEf?cienciesforCO,andCH3OH oncycled molybdenum electrodes.‘1 ElectrolysesinCO2saturated0.2M Na2SO4aqueoussolution. inparallelwithelectrolysis.Howeveranalysisofthe bAveraggcurrentdensity. solutionusedforexperiment2A inTable2byatomic55 ‘% faradaicef?cieny.InallcasesnomethanewasdetectedbyGC analysis. TABLE 5 absorption indicates no molybdenum is present to a limitof0.5uM. To lookfortheformationofinsoluble corrosion products the surface of the electrode was analyzed electrochemically. FIG. 5a shows the cyclic voltammetryofamolybdenumelectrodejustpretreated 60 withKOH/HF whileFIG.5billustratesthecaseofan electrodewhichhadbeentreatedinanidenticalmanner but had also been used to electrolyze a carbon dioxide solutionat—0.8VvsSCEfor76hours,passing40 time/min SCE uAcm”2 coul CO CH30H coulombandmakingmethanolwithafaradaicef?650d -0.8 120 14 ND! 24 ciency of 30%. It can be seen that the size of the waves 7 ~08 61 8.4 (0.6 230 for molybdenum oxide on the surface are qualitatively 7/’ -o.s 42 22 as 264 the same and no surface bound corrosion products are 15 -o.s 91 10 N.M.g 246 methanol during extended electrolysis (3 rd and 4 th entries in Table 5 ). However, in the case of cycled electrodes faradaic ef?ciencies do not decline signi? cantly with time. FIGS. 6 and 7 show the cyclic voltammetry for KOHHF pretreatedmolybdenumelectrodesincarbon dioxidesaturated0.2M Na2SO4,pH=4.2.Thecycling time in FIG. 6 is 7 minutes corresponding to the ?rst 8 Pretreatment SCE ,tACm—2 coul co CHgOH 4.4 118 N.D." 9.5 5.5 370 1-1c1 -o.7 49.5 I—1c1d -1.0 170 HCl -0.7 BC! -0.s HCl -0.s KOH/HF _o.s KOH/HF ~o.s 8.6 so 3.5 79 32.1 1.3 NM! 19 147 107 2.2 25 19.13.e 37o 0.3 240 91 10 NM! 246 “Allelectrodeswerecycledbetween—L0and+0.2V vsSCEbeforeelectr‘olysis. dSame electrode as previous experiment but oxide had turned black. ‘ND. = not detected. /'N.M. = not measured. EffectofCyclingTimeontheFaradaicEfficienciesforCO, andCHQOH ofmolybdenumelectrodes.” Cycling E/ j"/ Q/ Ef?ciencycPDF Image | ELECTROCHEMICAL REDUCTION OF AQUEOUS CO2 TO METHANOL

PDF Search Title:

ELECTROCHEMICAL REDUCTION OF AQUEOUS CO2 TO METHANOLOriginal File Name Searched:

US4609441.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |