PDF Publication Title:

Text from PDF Page: 004

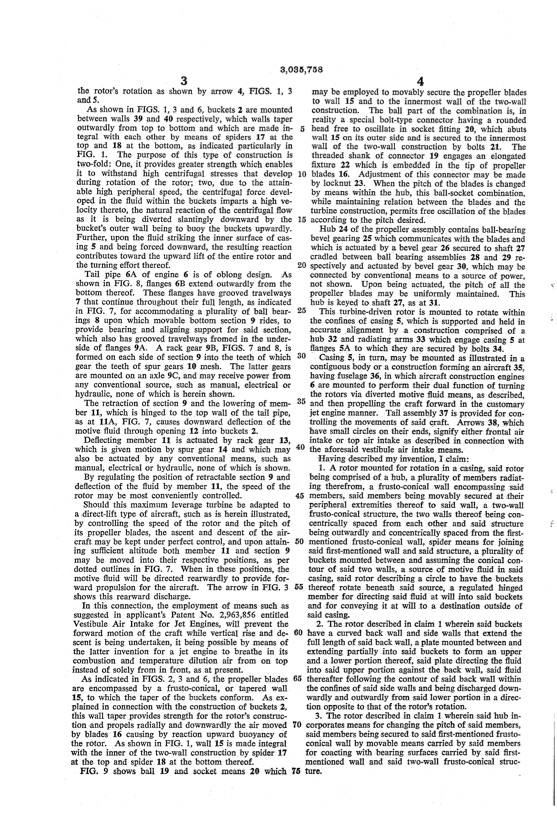

3,035,758 34 the rotor’s rotation as shown by arrow 4, FIGS. 1, 3 and5. may be employed to movably secure the propeller blades to wall 15 and to the innermost wall of the two-wall construction. Theballpartofthecombinationis,in reality a special bolt-type connector having a rounded head free to oscillate in socket ?tting 20, which abuts wall 15 on its outer side and is secured to the innermost wall of the two-wall construction by bolts 21. The threaded shank of connector 19 engages an elongated ?xture 22 which is embedded in the tip of propeller AsshowninFIGS.1,3and6,buckets2aremounted between walls 39 and 40 respectively, which walls taper outwardly from top to bottom and which are made in tegral with each other by means of spiders 17 at the top and 18 at the bottom, as indicated particularly in FIG. 1. The purpose of this type of construction is two-fold: One, itprovides greater strength which enables it to withstand high centrifugal stresses that develop 10 blades 16. Adjustment of this connector may be made duringrotationoftherotor;two,duetotheattain able high peripheral speed, the centrifugal force devel oped in the ?uid within the buckets imparts a high ve locity thereto, the natural reaction of the centrifugal ?ow as it is being diverted slantingly downward by the 15 accordingtothepitchdesired.’ bucket’s outer wall being to buoy the buckets upwardly. Further, upon the ?uid striking the inner surface of cas ing 5 and being forced downward, the resulting reaction contributes toward the upward lift of the entire rotor and the turning e?ort thereof. Hub 24 of the propeller assembly contains ball-bearing bevelgearing25whichcommunicateswiththebladesand which is actuated by a bevel gear 26 secured to shaft v27 cradled between ball bearing assemblies 28 and 29 re spectively and actuated by bevel gear 30, which may be connected by conventional means to a source of power, notshown. Uponbeingactuated,thepitchofalthe propeller blades may be uniformly maintained. This hub is keyed to shaft 27, as at 31. ' Tailpipe6Aofengine6isofoblongdesign. As showninFIG.8,?anges68extendoutwardlyfromthe bottom thereof. These ?anges have grooved travelways 7 that continue throughout their full length, as indicated in FIG. 7, for accommodating a plurality of ball bear ings 8 upon which movable bottom section 9 rides, to provide bearing and aligning support for said section, which also has grooved travelways fromed in the under side of ?anges 9A. A rack gear 93, FIGS. 7 and 8, is formedoneachsideofsection9intotheteethofwhich 30 .Casing5,inturn,maybemountedasillustratedina gear the teeth of spur gears 10 mesh. The latter gears are mounted on an axle 9C, and may receive power from any conventional source, such as manual, electrical or hydraulic, none of which is herein shown. Theretractionofsection9andtheloweringofmem ber 11, which is hinged to the top wall of the tail pipe, as at 11A, FIG. 7, causes downward de?ection of the motive ?uid through opening 12 into buckets 2. De?ecting member 11 is actuated by rack gear 13, whichisgivenmotionbyspurgear14andwhichmay 40 theaforesaidvestibuleairintakemeans. also be actuated by any conventional means, such as manual, electrical or hydraulic, none of which is shown. By regulating the position of retractable section 9 and de?ection of the ?uid by member 11, the speed of the rotor may be most conveniently controlled. Should this maximum leverage turbine be adapted to adirect-lift type of aircraft, such as is herein illustrated, by controlling the speed of the rotor and the pitch of ‘Havingdescribedmy invention,Iclaim: 1.A rotormountedforrotationinarcasing,saidrotor being comprised of a hub, aplurality of members radiat ing therefrom, a frusto-conical wall encompassing said 45 members, said members being movably secured at their peripheral extremities thereof to said wall, a two-wall frusto-conical structure, the two walls thereof being con centrically spaced from each other and .said structure being outwardly and concentrically spaced from the ?rst its propeller blades, the ascent and descent of the air craftmaybekeptunderperfectcontrol,anduponattain 50 mentionedfrusto-conicalwall,spidermeansforjoining ing su?icient altitude both member 11 and section 9 may be moved into their respective positions, as per dottedoutlinesinFIG.7. Wheninthesepositions,the motive ?uid will be directed rearwardly to provide for ward propulsion for the aircraft. The arrow in FIG. 3 55 thereof rotate beneath .said source, .a regulated hinged shows this rearward discharge. In .this connection, the employment of means such as suggested in applicant’s Patent .No. 2,963,856 entitled Vestibule Air Intake for Jet Engines, will prevent the forwardmotionofthecraftwhileverticalriseandde 60haveacurvedbackwallandsidewallsthatextendthe scent is being undertaken, it being possible by means of the latter invention for a jet engine to breathe in its combustion and temperature dilution air from on top instead of solely from in front, as at present. _ full length of said back wall, a plate mounted between and extending partiallyinto said buckets to form an'upper andyalowerportionthereof,saidplatedirectingthe?uid into said upper portion against the back wall, said ?uid AsindicatedinFIGS.2,3and6,thepropellerblades 65 thereafterfollowingthecontourofsaidbackwallwithin are encompassed by a frusto-conical, or tapered wall 15,towhichthetaperofthebucketsconform. Asex plained in connection with the’construction of buckets 2, this wall taperprovides strength for the rotor’s construc tionandpropelsradiallyanddownwardlytheairmoved 70 corporatesmeansforchangingthepitchof’saidmembers, by blades 16 causing by reaction upward buoyancy of the rotor. ,As shown in FIG}. 1, wall 15 is made integral with the inner of the two-wall constructionvby spider 17 at the top and‘ spider 18 at the bottom thereof. FIG. 9 shows ball 19 and socket means 20 which 75 ture. bylocknut23. Whenthepitchofthebladesischanged by means within the hub, this ball-socket combination, while maintaining relation between the blades and the turbineconstruction,permitsfreeoscillation‘of'theblades 25 This turbine-driven rotor is mounted to rotate within the con?nes of easing 5, which is supported and held in accurate alignment by a construction comprised of a hub 32 and radiating arms 33 which engage casing 5 at ?anges 5A to which they are secured by bolts 34. ' contiguous body or a construction forming an aircraft 35, having fuselage 36, in which aircraftconstruction engines 6 are mounted to perform their dual function of turning the rotors via diverted motive ?uid means, as described, 35 andthenpropellingthecraftforwardinthecustomary jetenginemanner. 'Tailassembly37isprovidedfor,con trollingthemovementsofsaidcraft. Arrows3,8,which have small circles on their ends, signify either frontal air intake or top air intake as described in connection with said?rst-mentionedWallandsaidstructure,.apluralityof buckets mounted between and assuming theconical con tourofsaidtwowalls,asourceofmotive?uidinsaid casing, said rotor describing a circle to have the-buckets member for directing said ?uid at will into said buckets and for conveying it at will .to a destination outside of saidcasing. '2. The rotor described in claim 1 wherein said buckets thecon?nesofsaidsidewallsandbeingdischargeddown wardlyandoutwardlyfromsaidlowerportioninadirec tion opposite to that of the rotor’s rotation. 3. The rotor described in claim 1 wherein said hub in~ saidmembers beingsecuredtosaid?rst-mentionedfrusto conical wall by movable means carried by said members for coacting with bearing surfaces carried by said ?rst mentioned wall and said two-wall frusto-conical strucPDF Image | Leverage Turbine

PDF Search Title:

Leverage TurbineOriginal File Name Searched:

US3035758.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |