PDF Publication Title:

Text from PDF Page: 008

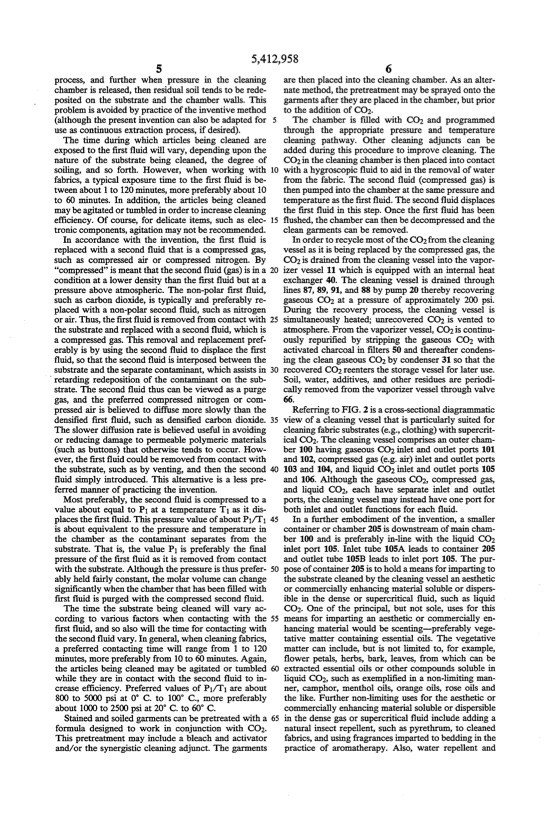

5,412,958 56 process, and further when pressure in the cleaning chamber is released, then residual soil tends to be rede posited on the substrate and the chamber walls. This problem is avoided by practice of the inventive method (althoughthepresentinventioncanalsobeadaptedfor use as continuous extraction process, ifdesired). are then placed into the cleaning chamber. As an alter nate method, the pretreatment may be sprayed onto the garmentsaftertheyareplacedinthechamber,butprior to the addition of C02. The chamber is?lled with CO2 and programmed through the appropriate pressure and temperature cleaning pathway. Other cleaning adjuncts can be added during this procedure to improve cleaning. The CO; inthe cleaning chamber isthen placed into contact The time during which articles being cleaned are exposed to the ?rst ?uid will vary, depending upon the nature of the substrate being cleaned, the degree of soiling, and so forth. However, when working with 10 with a hygroscopic ?uid to aid in the removal of water fabrics, a typical exposure time to the ?rst ?uid is be tween about 1 to 120 minutes, more preferably about 10 to 60 minutes. In addition, the articles being cleaned may be agitated or tumbled inorder to increase cleaning ef?ciency. Of course, for delicate items, such as elec troniccomponents, agitationmay notberecommended. from the fabric. The second ?uid (compressed gas) is then pumped into the chamber at the same pressure and temperatureasthe?rst?uid.The secondfluiddisplaces the ?rst ?uid in this step. Once the ?rst ?uid has been ?ushed, the chamber can then be decompressed and the clean garments can be removed. InordertorecyclemostoftheCO2fromthecleaning vesselasitisbeingreplacedbythecompressedgas,the CO2 isdrained from the cleaning vessel into the vapor izer vessel 11 which is equipped with an internal heat exchanger 40. The cleaning vessel is drained through lines 87, 89, 91, and 88 by pump 20 thereby recovering gaseous CO; at a pressure of approximately 200 psi. During the recovery process, the cleaning vessel is simultaneously heated; unrecovered CO2 is vented to In accordance with the invention, the ?rst ?uid is replaced with a second ?uid that is a compressed gas, such as compressed air or compressed nitrogen. By “compressed” ismeant that the second ?uid (gas) isin a condition at a lower density than the ?rst ?uid but at a pressure above atmospheric. The non-polar ?rst ?uid, such as carbon dioxide, is typically and preferably re placed with a non-polar second ?uid, such as nitrogen or air.Thus, the ?rst ?uid isremoved from contact with thesubstrateandreplacedwithasecond?uid,whichis atmosphere.Fromthevaporizervessel,CO2iscontinu a compressed gas. This removal and replacement pref ously repuri?ed by stripping the gaseous CO; with erablyisbyusingthesecond?uidtodisplacethe?rst activatedcharcoalin?lters50andthereaftercondens ?uid, so that the second ?uid is interposed between the substrate and the separate contaminant, which assists in 'retarding redeposition of the contaminant on the sub ing the clean gaseous CO2 by condenser 31 so that the recovered CO2 reenters the storage vessel for later use. Soil, water, additives, and other residues are periodi callyremovedfromthevaporizervesselthroughvalve 66. ReferringtoFIG.2isacross-sectionaldiagrammatic view of a cleaning vessel that is particularly suited for cleaningfabricsubstrates(e.g.,clothing)withsupercrit ical C01. The cleaning vessel comprises an outer cham ber 100 having gaseous CO2 inlet and outlet ports 101 and 102, compressed gas (e.g. air) inlet and outlet ports strate. The second ?uid thus can be viewed as a purge gas, and the preferred compressed nitrogen or com pressedairisbelievedtodiffusemore slowlythanthe densi?ed ?rst ?uid, such as densi?ed carbon dioxide. The slowerdiffusionrateisbelievedusefulinavoiding or reducing damage to permeable polymeric materials (such asbuttons) that otherwise tends to occur. How ever, the ?rst ?uid could be removed from contact with thesubstrate,suchasbyventing,andthenthesecond40 103and104,andliquidCO2inletandoutletports105 ?uid simply introduced. This alternative is a less pre ferred manner of practicing the invention. Most preferably, the second ?uid is compressed to a value about equal to P1 at a temperature T1 as it dis placesthe?rst?uid.ThispressurevalueofaboutP1/T1 45 is about equivalent to the pressure and temperature in the chamber as the contaminant separates from the substrate. That is, the value P1 is preferably the ?nal pressure of the ?rst ?uid as itisremoved from contact withthesubstrate.Althoughthepressureisthusprefer ably held fairly constant, the molar volume can change signi?cantly when the chamber that has been ?lled with ?rst ?uid is purged with the compressed second ?uid. and 106. Although the gaseous CO2, compressed gas, and liquid CO2, each have separate inlet and outlet ports, the cleaning vessel may instead have one port for both inlet and outlet functions for each ?uid. In a further embodiment of the invention, a smaller container or chamber 205 is downstream of main cham ber 100 and is preferably in-line with the liquid CO2 inlet port 105. Inlet tube 105A leads to container 205 and outlet tube 105B leads to inlet port 105. The pur pose of container 205 isto hold a means for imparting to the substrate cleaned by the cleaning vessel an aesthetic or commercially enhancing material soluble or dispers ible in the dense or supercritical ?uid, such as liquid CO2. One of the principal, but not sole, uses for this The time the substrate being cleaned will vary ac cording to various factors when contacting with the 55 means for imparting an aesthetic or commercially en ?rst ?uid, and so also will the time for contacting with the second ?uid vary. In general, when cleaning fabrics, a preferred contacting time will range from 1 to 120 minutes, more preferably from 10 to 60 minutes. Again, thearticlesbeingcleanedmaybeagitatedortumbled60 extractedessentialoilsorothercompoundssolublein while they are in contact with the second ?uid to in crease ef?ciency. Preferred values of P1/T1 are about 800 to 5000 psi at 0° C. to 100° C., more preferably about 1000 to 2500 psi at 20° C. to 60° C. liquid CO2, such as exempli?ed in a non-limiting man ner, camphor, menthol oils, orange oils, rose oils and the like. Further non-limiting uses for the aesthetic or commercially enhancing material soluble or dispersible Stainedandsoiledgarmentscanbepretreatedwitha65 inthedensegasorsupercritical?uidincludeaddinga formula designed to work in conjunction with CO2. natural insect repellent, such as pyrethrum, to cleaned This pretreatment may include a bleach and activator fabrics,andusingfragrancesimpartedtobeddinginthe and/orthesynergisticcleaningadjunct.Thegarments practiceofaromatherapy.Also,waterrepellentand hancing material would be seeming-preferably vege tative matter containing essential oils. The vegetative matter can include, but is not limited to, for example, ?ower petals, herbs, bark, leaves, from which can bePDF Image | LIQUID SUPERCRITICAL CARBON DIOXIDE DRY CLEANING SYSTEM

PDF Search Title:

LIQUID SUPERCRITICAL CARBON DIOXIDE DRY CLEANING SYSTEMOriginal File Name Searched:

US5412958.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |