PDF Publication Title:

Text from PDF Page: 008

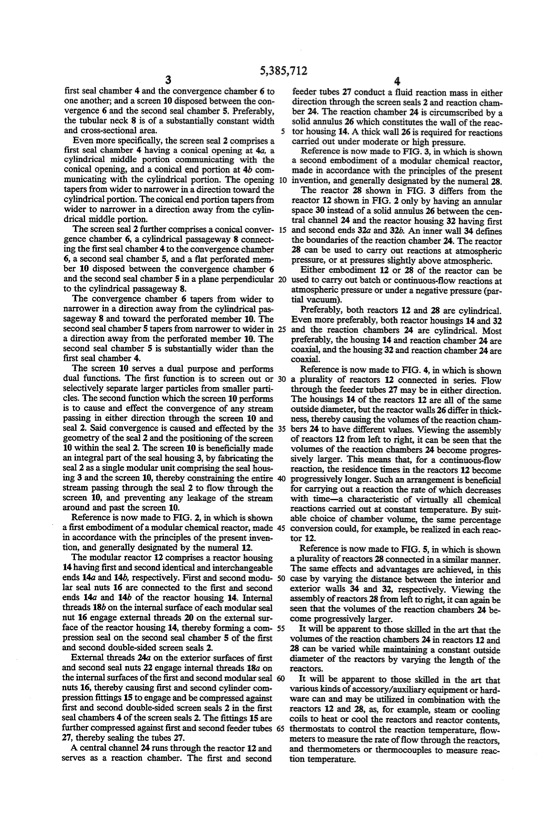

3 ?rst seal chamber 4 and the convergence chamber 6 to one another; and a screen 10 disposed between the con vergence 6 and the second seal chamber 5. Preferably, the tubular neck 8 is of a substantially constant width andcross-sectionalarea. Even more speci?cally, the screen seal 2 comprises a ?rst seal chamber 4 having a conical opening at 4a, a cylindrical middle portion communicating with the conical opening, and a conical end portion at 4b com municating with the cylindrical portion. The opening tapers from wider to narrower in a direction toward the cylindricalportion.Theconicalendportiontapersfrom wider to narrower in a direction away from the cylin dricalmiddleportion. 4 feeder tubes 27 conduct a ?uid reaction mass in either direction through the screen seals 2 and reaction cham ber 24. The reaction chamber 24 iscircumscribed by a solid annulus 26 which constitutes the wall of the reac 5 torhousing14.Athickwall26isrequiredforreactions carried out under moderate or high pressure. Reference isnow made toFIG. 3,inwhich isshown a second embodiment of a modular chemical reactor, made in accordance with the principles of the present invention,andgenerallydesignatedbythenumeral28. The reactor 28 shown in FIG. 3 differs from the reactor 12 shown in FIG. 2 only by having an annular space 30 instead of a solid annulus 26 between the cen tral channel 24 and the reactor housing 32 having ?rst 5,385,712 Thescreenseal2furthercomprisesaconicalconver 15 andsecondends320and32b.Aninnerwall34de?nes gence chamber 6, a cylindrical passageway 8 connect ingthe?rstsealchamber4totheconvergencechamber 6,a second seal chamber 5,and a ?at perforated mem ber 10 disposed between the convergence chamber 6 andthesecondsealchamber5inaplaneperpendicular20 usedtocarryoutbatchorcontinuous-?owreactionsat to the cylindrical passageway 8. The convergence chamber 6 tapers from wider to narrower in a direction away from the cylindrical pas sageway 8 and toward the perforated member 10. The secondsealchamber5tapersfromnarrowertowiderin25 andthereactionchambers24arecylindrical.Most a direction away from the perforated member 10. The second seal chamber 5 is substantially wider than the ?rst seal chamber 4. The screen 10 serves a dual purpose and performs dual functions. The ?rst function is to screen out or 30 a plurality of reactors 12 connected in series. Flow selectivelyseparatelargerparticlesfromsmallerparti cles. The second function which the screen 10 performs is to cause and effect the convergence of any stream passing in either direction through the screen 10 and seal2.Saidconvergenceiscausedandeffectedbythe 35 bers24tohavedifferentvalues.Viewingtheassembly geometry of the seal 2 and the positioning of the screen 10 within the seal 2. The screen 10 isbene?cially made anintegralpartofthesealhousing3,byfabricatingthe seal2asasinglemodularunitcomprisingthesealhous ing3andthescreen10,therebyconstrainingtheentire4-0 progressivelylonger.Suchanarrangementisbene?cial streampassingthroughtheseal2to?ow throughthe screen 10, and preventing any leakage of the stream around and past the screen 10. Reference isnow made toFIG. 2,inwhich isshown a?rstembodimentofamodularchemicalreactor,made 45 conversioncould,forexample,berealizedineachreac in accordance with the principles of the present inven tion, and generally designated by the numeral 12. The modular reactor 12 comprises a reactor housing 14having?rstandsecondidenticalandinterchangeable ends14aand14b,respectively.Firstandsecondmodu 50 casebyvaryingthedistancebetweentheinteriorand lar seal nuts 16 are connected to the ?rst and second ends 14a and 14b of the reactor housing 14. Internal threads 18b on the internal surface of each modular seal nut 16 engage external threads 20 on the external sur faceofthereactorhousing14,therebyformingacom 55 pression seal on the second seal chamber 5 of the ?rst and second double-sided screen seals 2. External threads 240 on the exterior surfaces of ?rst and second seal nuts 22 engage internal threads 18a on theinternalsurfacesofthe?rstandsecondmodularseal 60 nuts 16, thereby causing ?rst and second cylinder com pression?ttings15toengageandbecompressedagainst ?rst and second double-sided screen seals 2 in the ?rst seal chambers 4 of the screen seals 2. The ?ttings 15 are furthercompressedagainst?rstandsecondfeedertubes65 thermostatstocontrolthereactiontemperature,?ow 27,therebysealingthetubes27. A centralchannel24runsthroughthereactor12and serves as a reaction chamber. The ?rst and second tiontemperature. the boundaries of the reaction chamber 24. The reactor 28 can be used to carry out reactions at atmospheric pressure, or at pressures slightly above atmospheric. Either embodiment 12 or 28 of the reactor can be atmosphericpressureorunderanegativepressure(par tialvacuum). Preferably, both reactors 12 and 28 are cylindrical. Even more preferably, both reactor housings 14 and 32 preferably, the housing 14 and reaction chamber 24 are coaxial,andthehousing32andreactionchamber24are coaxial. Reference isnow made toFIG. 4,inwhich isshown through the feeder tubes 27 may be in either direction. The housings 14 of the reactors 12 are all of the same outsidediameter,butthereactorwalls26differinthick ness,therebycausingthevolumesofthereactioncham of reactors 12 from left to right, it can be seen that the volumes of the reaction chambers 24 become progres sively larger. This means that, for a continuous-?ow reaction,theresidencetimesinthereactors12become for carrying out a reaction the rate of which decreases with time—a characteristic of virtually all chemical reactions carried out at constant temperature. By suit able choice of chamber volume, the same percentage tor 12. Reference isnow made toFIG. 5,inwhich isshown a plurality of reactors 28 connected in a similar manner. The same effects and advantages are achieved, in this exterior walls 34 and 32, respectively. Viewing the assemblyofreactors28fromlefttoright,itcanagainbe seen that the volumes of the reaction chambers 24 be come progressivelylarger. It will be apparent to those skilled in the art that the volumes of the reaction chambers 24 in reactors 12 and 28 can be varied while maintaining a constant outside diameter of the reactors by varying the length of the reactors. It will be apparent to those skilled in the art that variouskindsofaccessory/auxiliaryequipmentorhard ware can and may be utilized in combination with the reactors 12 and 28, as, for example, steam or cooling coils to heat or cool the reactors and reactor contents, meterstomeasuretherateof?ow throughthereactors, and thermometers or thermocouples to measure reacPDF Image | MODULAR CHEMICAL REACTOR

PDF Search Title:

MODULAR CHEMICAL REACTOROriginal File Name Searched:

US5385712.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |