PDF Publication Title:

Text from PDF Page: 004

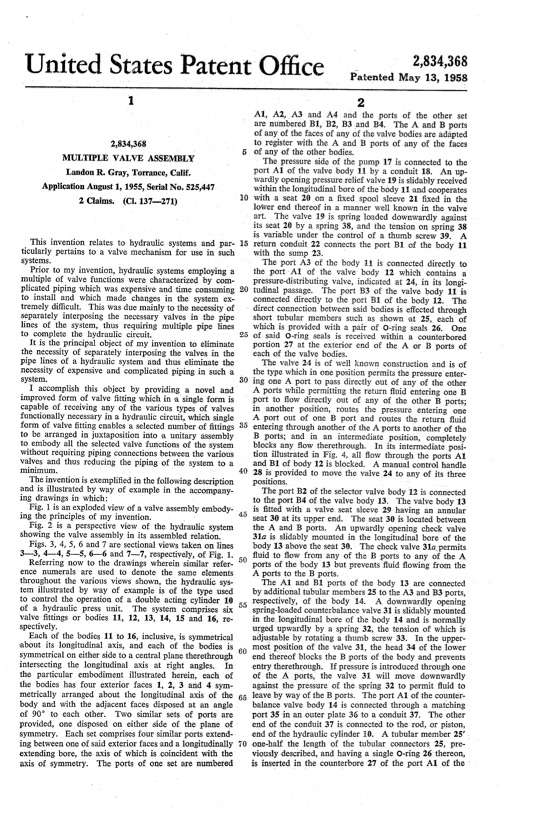

UnitedStatesPatent‘0 T‘ ‘2,834,368 ice’ PatentedMay 13,1958 1 2,834,368 MULTIPLE VALVE ASSEMBLY Landon R. Gray, Torrance, Calif. ApplicationAugust1,1955,SerialNo.525,447 2Claims. (Cl.137-271) 2 A1, A2, A3 and A4 and the ports of the other set are numbered B1, B2, B3 ‘and B4. The A and B ports of any of the faces of any of the valve bodies are adapted toregister with the A and B ports of any of the faces of any of the other bodies. The pressure side of the pump 17 is connected to the port A1 of the valve body 11 by a conduit 18. An up wardlyopeningpressurereliefvalve19isslidablyreceived within the longitudinal bore of the body 11 and cooperates 10 with a seat 20 on a ?xed spool sleeve 21 ?xed in the lower end thereof in a manner well known in the valve art. The valve 19 is.springloaded downwardly against its seat 20 by a spring 38, and the tension on spring 38 isvariableunderthecontrolofathumbscrew39. A This invention relates to hydraulic systems and par 15 return conduit 22 connects the port B1 of the body 11 ticularly pertains to a valve mechanism for use in such systems. with the sump 23. ' The port A3 of the body 11 is connected directly to Prior to my invention, hydraulic systems employing a multiple of valve functions were characterized by com plicatedpipingwhichwasexpensiveandtimeconsuming20tudinalpassage. Theport33ofthevalvebody11is to install and which made changes in the system ex tremelydi?icult. Thiswasduemainlytothenecessityof separately interposing the necessary valves in the pipe lines of the system, thus requiring multiple pipe lines to complete the hydraulic circuit. Itistheprincipalobjectofmy inventiontoeliminate the necessity of separately interposing the valves in the pipe lines of a hydraulic system and thus eliminate the necessity of expensive and complicated piping in such a connecteddirectlytotheportB1ofthebody12. The direct connection between said bodies is effected through short tubular members such as shown ‘at 25,v each of whichisprovidedwithapairofO-ringseals26. One of said O-ring seals is received within a’ counterbored portion 27 at the exterior end of the A or B ports of each of the valve bodies. The valve 24 is of well known construction and is of the type which in one position permits the pressure enter system. 30 ing one A port to pass directly out of any of the other I accomplish this object by providing a novel and improvedformofvalve?ttingwhichina'singleformis 'portto?owdirectlyoutofanyoftheotherBports; capable of receiving any of the various types of valves functionally necessary in a hydraulic circuit, which single form of valve ?tting enables a selected number of ?ttings to be arranged in juxtaposition into a unitary assembly to embody all the selected valve functions of the system without requiring piping connections between the various valves and thus reducing the piping of the system to a minimum._ > ' in another position, routes the pressure entering one A port out of one B port and routes the return ?uid enteringthroughanotheroftheA portstoanotherofthe B ports; and in an intermediate position, completely blocksany?owtherethrough. Initsintermediateposi tion illustrated in Fig. 4, all flow through the ports A1 andB1ofbody12isblocked. Amanualcontrolhandle 40 28isprovidedtomovethevalve24toanyofitsthree Theinventionisexempli?edinthefollowingdescription positions. 1 and is illustrated by way of example in the accompany ing drawings in which: Fig. 1 is an exploded view of a valve assembly embody- . ingtheprinciplesofmyinvention. .' Fig. 2 is a perspective view of the hydraulic system showing the valve assembly in its assembled relation. Figs. 3, 4, 5, 6 and 7 are sectional views taken on lines 3-3, 4-4, 5——5, 6-6 and 7—-7, respectively, of Fig. 1. Referring now to thedrawings wherein similar refer ence numerals are used to denote the same elements throughout the various views shown, the hydraulic sys tem illustrated by way of example is of the type used to control the operation of a double acting cylinder, 10 of a hydraulic press unit. The system comprises six valve ?ttings or bodies 11, 12, 13, 14, 15 and 16, re spectively. The port B2 of the selector valve body 12 is connected totheportB4ofthevalvebody13. Thevalvebody13 is ?tted with a valve seat sleeve 29 having an annular seat30atitsupperend. Theseat30islocatedbetween the A and B ports. An upwardly opening check valve 31a is slidably mounted in the longitudinal bore of the body13abovetheseat30. Thecheckvalve31a_permits ?uid to flow from any of the B [ports to any of the A ports of the body 13 but prevents ?uid ?owing from the A ports to the B ports. The A1 and B1 ports of the body 13 are connected byadditionaltubularmembers25totheA3 andB3ports, respectively, of the body 14. A downwardly opening spring-loaded counterbalance valve 31 is slidably mounted in the.longitudinal bore of the body 14 and is normally urged upwardly by a spring 32, the tension of which is adjustablebyrotatingathumbscrew33. Intheupper most position of the valve 31, the head 34 of the lower Each of the bodies 11 to 16, inclusive, is symmetrical about its longitudinal axis, and each of the bodies is symmetricaloneithersidetoacentralplanetherethrough 60 endthereofblockstheBportsofthebodyandprevents ' intersecting the longitudinal axis at right angles. In the particular embodiment illustrated herein, each, of the bodies has four exterior faces 1, 2, 3 and 4 sym metrically arranged about the longitudinal axis of the body and with the adjacent faces disposed at an angle of 90° to each other. Two similar sets of ports are provided, one disposed on either side of the plane of symmetry. Eachsetcomprisesfoursimilarportsextend ing between one of said exterior faces and a longitudinally extending bore, the axis of which is coincident with the axisofsymmetry. Theportsofoneset,arenumbered the port‘A1 of the valve body 12 which contains a pressure-distributing valve, indicated at 24, in its longi A portswhilepermittingthereturn?uidenteringoneB entrytherethrough. Ifpressureisintroducedthroughone of the A .ports, the valve 31 will move downwardly against the pressure of the spring 32 to permit ?uid to leavebywayoftheBports. TheportA1ofthecounter. balance valve body 14 is connected through a matching portv35inanouterplate36toaconduit37. Theother end of the conduit 37 is connected to the rod, or piston, end of the hydraulic cylinder 10. A tubular member 25’ -_ one-half the length of the tubular connectors 25, pre viously described, and having a single O-ring 26thereon, isinserted‘inthecounterbore27oftheportA1ofthe'PDF Image | MULTIPLE VALVE ASSEMBLY

PDF Search Title:

MULTIPLE VALVE ASSEMBLYOriginal File Name Searched:

US2834368.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |