PDF Publication Title:

Text from PDF Page: 046

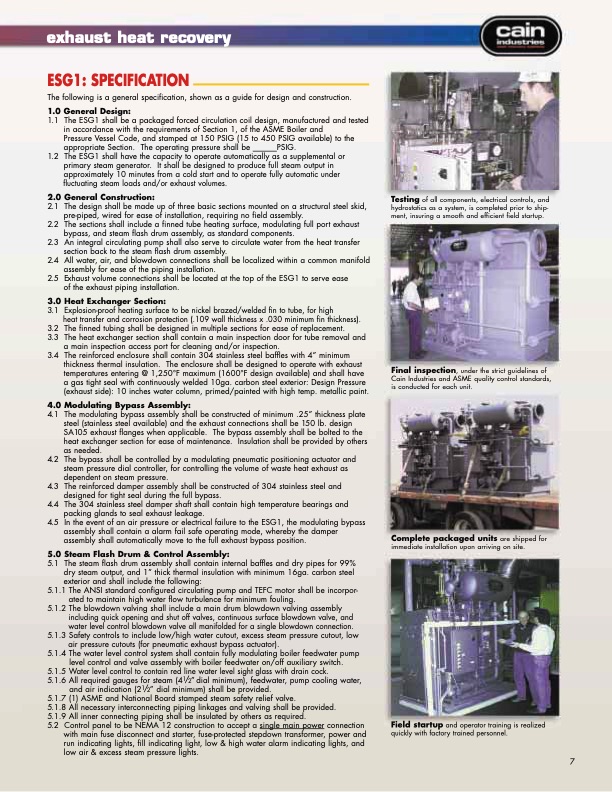

exhaust heat recovery ESG1: SPECIFICATION The following is a general specification, shown as a guide for design and construction. 1.0 General Design: 1.1 The ESG1 shall be a packaged forced circulation coil design, manufactured and tested in accordance with the requirements of Section 1, of the ASME Boiler and Pressure Vessel Code, and stamped at 150 PSIG (15 to 450 PSIG available) to the appropriate Section. The operating pressure shall be ______PSIG. 1.2 The ESG1 shall have the capacity to operate automatically as a supplemental or primary steam generator. It shall be designed to produce full steam output in approximately 10 minutes from a cold start and to operate fully automatic under fluctuating steam loads and/or exhaust volumes. 2.0 General Construction: 2.1 The design shall be made up of three basic sections mounted on a structural steel skid, pre-piped, wired for ease of installation, requiring no field assembly. 2.2 The sections shall include a finned tube heating surface, modulating full port exhaust bypass, and steam flash drum assembly, as standard components. 2.3 An integral circulating pump shall also serve to circulate water from the heat transfer section back to the steam flash drum assembly. 2.4 All water, air, and blowdown connections shall be localized within a common manifold assembly for ease of the piping installation. 2.5 Exhaust volume connections shall be located at the top of the ESG1 to serve ease of the exhaust piping installation. 3.0 Heat Exchanger Section: 3.1 Explosion-proof heating surface to be nickel brazed/welded fin to tube, for high heat transfer and corrosion protection (.109 wall thickness x .030 minimum fin thickness). 3.2 The finned tubing shall be designed in multiple sections for ease of replacement. 3.3 The heat exchanger section shall contain a main inspection door for tube removal and a main inspection access port for cleaning and/or inspection. 3.4 The reinforced enclosure shall contain 304 stainless steel baffles with 4” minimum thickness thermal insulation. The enclosure shall be designed to operate with exhaust temperatures entering @ 1,250°F maximum (1600°F design available) and shall have a gas tight seal with continuously welded 10ga. carbon steel exterior: Design Pressure (exhaust side): 10 inches water column, primed/painted with high temp. metallic paint. 4.0 Modulating Bypass Assembly: 4.1 The modulating bypass assembly shall be constructed of minimum .25” thickness plate steel (stainless steel available) and the exhaust connections shall be 150 lb. design SA105 exhaust flanges when applicable. The bypass assembly shall be bolted to the heat exchanger section for ease of maintenance. Insulation shall be provided by others as needed. 4.2 The bypass shall be controlled by a modulating pneumatic positioning actuator and steam pressure dial controller, for controlling the volume of waste heat exhaust as dependent on steam pressure. 4.3 The reinforced damper assembly shall be constructed of 304 stainless steel and designed for tight seal during the full bypass. 4.4 The 304 stainless steel damper shaft shall contain high temperature bearings and packing glands to seal exhaust leakage. 4.5 In the event of an air pressure or electrical failure to the ESG1, the modulating bypass assembly shall contain a alarm fail safe operating mode, whereby the damper assembly shall automatically move to the full exhaust bypass position. 5.0 Steam Flash Drum & Control Assembly: 5.1 The steam flash drum assembly shall contain internal baffles and dry pipes for 99% dry steam output, and 1” thick thermal insulation with minimum 16ga. carbon steel exterior and shall include the following: 5.1.1 The ANSI standard configured circulating pump and TEFC motor shall be incorpor- ated to maintain high water flow turbulence for minimum fouling. 5.1.2 The blowdown valving shall include a main drum blowdown valving assembly including quick opening and shut off valves, continuous surface blowdown valve, and water level control blowdown valve all manifolded for a single blowdown connection. 5.1.3 Safety controls to include low/high water cutout, excess steam pressure cutout, low air pressure cutouts (for pneumatic exhaust bypass actuator). 5.1.4 The water level control system shall contain fully modulating boiler feedwater pump level control and valve assembly with boiler feedwater on/off auxiliary switch. 5.1.5 Water level control to contain red line water level sight glass with drain cock. 5.1.6 All required gauges for steam (41/2” dial minimum), feedwater, pump cooling water, and air indication (21/2” dial minimum) shall be provided. 5.1.7 (1) ASME and National Board stamped steam safety relief valve. 5.1.8 All necessary interconnecting piping linkages and valving shall be provided. 5.1.9 All inner connecting piping shall be insulated by others as required. 5.2 Control panel to be NEMA 12 construction to accept a single main power connection with main fuse disconnect and starter, fuse-protected stepdown transformer, power and run indicating lights, fill indicating light, low & high water alarm indicating lights, and low air & excess steam pressure lights. Testing of all components, electrical controls, and hydrostatics as a system, is completed prior to ship- ment, insuring a smooth and efficient field startup. Final inspection, under the strict guidelines of Cain Industries and ASME quality control standards, is conducted for each unit. Complete packaged units are shipped for immediate installation upon arriving on site. Field startup and operator training is realized quickly with factory trained personnel. 7PDF Image | Powerhouse Exhaust Gas Waste Heat to Energy Project

PDF Search Title:

Powerhouse Exhaust Gas Waste Heat to Energy ProjectOriginal File Name Searched:

waste_heat_to_energy_feasibility_study.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |