PDF Publication Title:

Text from PDF Page: 050

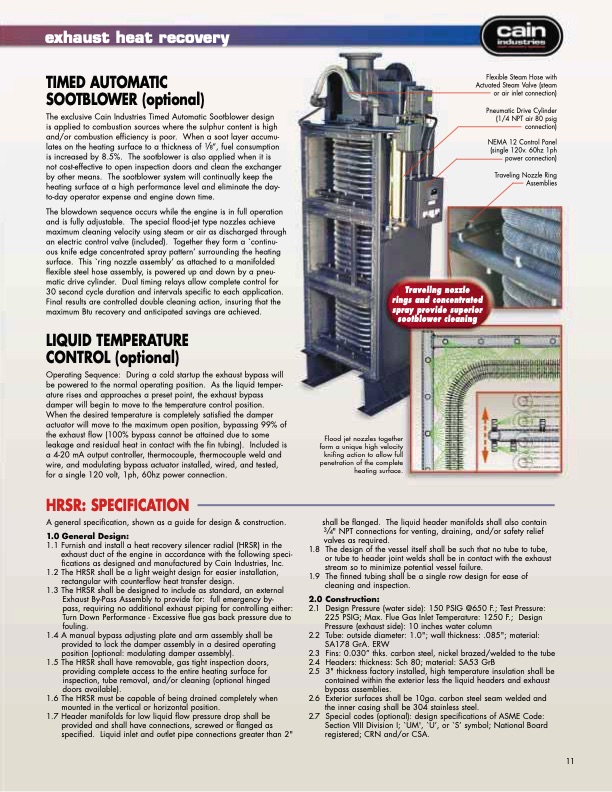

exhaust heat recovery TIMED AUTOMATIC SOOTBLOWER (optional) The exclusive Cain Industries Timed Automatic Sootblower design is applied to combustion sources where the sulphur content is high and/or combustion efficiency is poor. When a soot layer accumu- lates on the heating surface to a thickness of 1/8”, fuel consumption is increased by 8.5%. The sootblower is also applied when it is not cost-effective to open inspection doors and clean the exchanger by other means. The sootblower system will continually keep the heating surface at a high performance level and eliminate the day- to-day operator expense and engine down time. The blowdown sequence occurs while the engine is in full operation and is fully adjustable. The special flood-jet type nozzles achieve maximum cleaning velocity using steam or air as discharged through an electric control valve (included). Together they form a `continu- ous knife edge concentrated spray pattern’ surrounding the heating surface. This `ring nozzle assembly’ as attached to a manifolded flexible steel hose assembly, is powered up and down by a pneu- matic drive cylinder. Dual timing relays allow complete control for 30 second cycle duration and intervals specific to each application. Final results are controlled double cleaning action, insuring that the maximum Btu recovery and anticipated savings are achieved. LIQUID TEMPERATURE CONTROL (optional) Operating Sequence: During a cold startup the exhaust bypass will be powered to the normal operating position. As the liquid temper- ature rises and approaches a preset point, the exhaust bypass damper will begin to move to the temperature control position. When the desired temperature is completely satisfied the damper actuator will move to the maximum open position, bypassing 99% of the exhaust flow (100% bypass cannot be attained due to some leakage and residual heat in contact with the fin tubing). Included is a 4-20 mA output controller, thermocouple, thermocouple weld and wire, and modulating bypass actuator installed, wired, and tested, for a single 120 volt, 1ph, 60hz power connection. HRSR: SPECIFICATION A general specification, shown as a guide for design & construction. 1.0 General Design: 1.1 Furnish and install a heat recovery silencer radial (HRSR) in the exhaust duct of the engine in accordance with the following speci- fications as designed and manufactured by Cain Industries, Inc. 1.2 The HRSR shall be a light weight design for easier installation, rectangular with counterflow heat transfer design. 1.3 The HRSR shall be designed to include as standard, an external Exhaust By-Pass Assembly to provide for: full emergency by- pass, requiring no additional exhaust piping for controlling either: Turn Down Performance - Excessive flue gas back pressure due to fouling. 1.4 A manual bypass adjusting plate and arm assembly shall be provided to lock the damper assembly in a desired operating position (optional: modulating damper assembly). 1.5 The HRSR shall have removable, gas tight inspection doors, providing complete access to the entire heating surface for inspection, tube removal, and/or cleaning (optional hinged doors available). 1.6 The HRSR must be capable of being drained completely when mounted in the vertical or horizontal position. 1.7 Header manifolds for low liquid flow pressure drop shall be provided and shall have connections, screwed or flanged as specified. Liquid inlet and outlet pipe connections greater than 2" Flexible Steam Hose with Actuated Steam Valve (steam or air inlet connection) Pneumatic Drive Cylinder (1/4 NPT air 80 psig connection) NEMA 12 Control Panel (single 120v. 60hz 1ph power connection) Traveling Nozzle Ring Assemblies Traveling nozzle rings and concentrated spray provide superior sootblower cleaning Flood jet nozzles together form a unique high velocity knifing action to allow full penetration of the complete heating surface. 1.8 1.9 shall be flanged. The liquid header manifolds shall also contain 3/4" NPT connections for venting, draining, and/or safety relief valves as required. The design of the vessel itself shall be such that no tube to tube, or tube to header joint welds shall be in contact with the exhaust stream so to minimize potential vessel failure. The finned tubing shall be a single row design for ease of cleaning and inspection. 2.0 Construction: 2.1 Design Pressure (water side): 150 PSIG @650 F.; Test Pressure: 225 PSIG; Max. Flue Gas Inlet Temperature: 1250 F.; Design Pressure (exhaust side): 10 inches water column 2.2 Tube: outside diameter: 1.0"; wall thickness: .085"; material: SA178 GrA. ERW 2.3 Fins: 0.030” thks. carbon steel, nickel brazed/welded to the tube 2.4 Headers: thickness: Sch 80; material: SA53 GrB 2.5 3" thickness factory installed, high temperature insulation shall be contained within the exterior less the liquid headers and exhaust bypass assemblies. 2.6 Exterior surfaces shall be 10ga. carbon steel seam welded and the inner casing shall be 304 stainless steel. 2.7 Special codes (optional): design specifications of ASME Code: Section VIII Division I; `UM', `U’, or `S’ symbol; National Board registered; CRN and/or CSA. 11PDF Image | Powerhouse Exhaust Gas Waste Heat to Energy Project

PDF Search Title:

Powerhouse Exhaust Gas Waste Heat to Energy ProjectOriginal File Name Searched:

waste_heat_to_energy_feasibility_study.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |