PDF Publication Title:

Text from PDF Page: 029

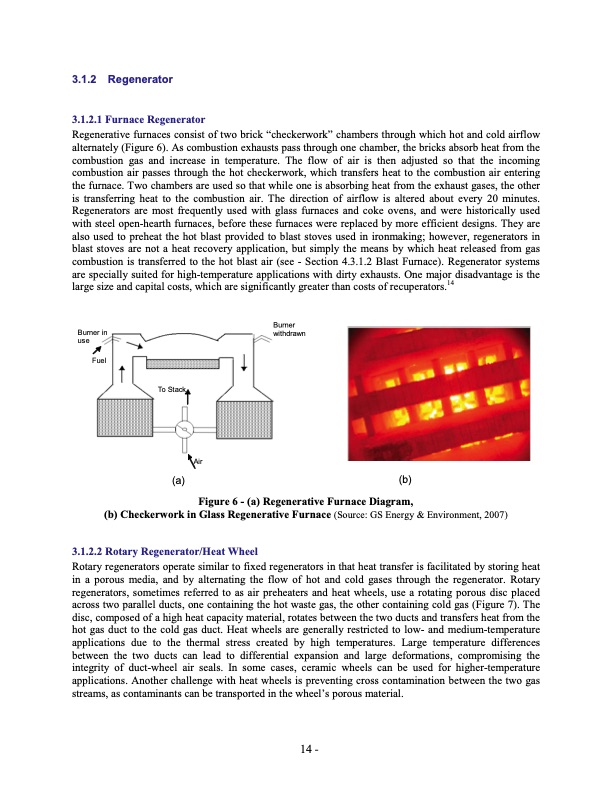

3.1.2 Regenerator 3.1.2.1 Furnace Regenerator Regenerative furnaces consist of two brick “checkerwork” chambers through which hot and cold airflow alternately (Figure 6). As combustion exhausts pass through one chamber, the bricks absorb heat from the combustion gas and increase in temperature. The flow of air is then adjusted so that the incoming combustion air passes through the hot checkerwork, which transfers heat to the combustion air entering the furnace. Two chambers are used so that while one is absorbing heat from the exhaust gases, the other is transferring heat to the combustion air. The direction of airflow is altered about every 20 minutes. Regenerators are most frequently used with glass furnaces and coke ovens, and were historically used with steel openhearth furnaces, before these furnaces were replaced by more efficient designs. They are also used to preheat the hot blast provided to blast stoves used in ironmaking; however, regenerators in blast stoves are not a heat recovery application, but simply the means by which heat released from gas combustion is transferred to the hot blast air (see Section 4.3.1.2 Blast Furnace). Regenerator systems are specially suited for hightemperature applications with dirty exhausts. One major disadvantage is the large size and capital costs, which are significantly greater than costs of recuperators.14 Burner in use Fuel Burner withdrawn To Stack Air (a) (b) Figure 6 (a) Regenerative Furnace Diagram, (b) Checkerwork in Glass Regenerative Furnace (Source: GS Energy & Environment, 2007) 3.1.2.2 Rotary Regenerator/Heat Wheel Rotary regenerators operate similar to fixed regenerators in that heat transfer is facilitated by storing heat in a porous media, and by alternating the flow of hot and cold gases through the regenerator. Rotary regenerators, sometimes referred to as air preheaters and heat wheels, use a rotating porous disc placed across two parallel ducts, one containing the hot waste gas, the other containing cold gas (Figure 7). The disc, composed of a high heat capacity material, rotates between the two ducts and transfers heat from the hot gas duct to the cold gas duct. Heat wheels are generally restricted to low and mediumtemperature applications due to the thermal stress created by high temperatures. Large temperature differences between the two ducts can lead to differential expansion and large deformations, compromising the integrity of ductwheel air seals. In some cases, ceramic wheels can be used for highertemperature applications. Another challenge with heat wheels is preventing cross contamination between the two gas streams, as contaminants can be transported in the wheel’s porous material. 14 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |