PDF Publication Title:

Text from PDF Page: 038

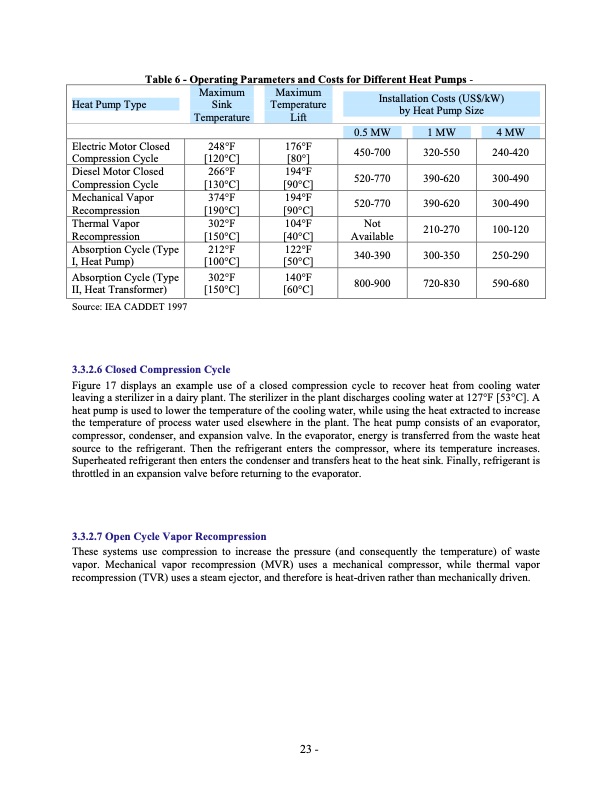

Table 6 Operating Parameters and Costs for Different Heat Pumps Heat Pump Type Maximum Temperature Lift Installation Costs (US$/kW) by Heat Pump Size 0.5 MW 1 MW 4 MW Electric Motor Closed Compression Cycle Diesel Motor Closed Compression Cycle Mechanical Vapor Recompression Thermal Vapor Recompression Absorption Cycle (Type I, Heat Pump) Absorption Cycle (Type II, Heat Transformer) Source: IEA CADDET 1997 248°F [120°C] 266°F [130°C] 374°F [190°C] 302°F [150°C] 212°F [100°C] 302°F [150°C] 176°F [80°] 194°F [90°C] 194°F [90°C] 450700 320550 520770 390620 520770 390620 240420 300490 300490 104°F Not [40°C] 122°F [50°C] 140°F [60°C] 210270 100120 250290 590680 Available 340390 300350 800900 720830 3.3.2.6 Closed Compression Cycle Maximum Sink Temperature Figure 17 displays an example use of a closed compression cycle to recover heat from cooling water leaving a sterilizer in a dairy plant. The sterilizer in the plant discharges cooling water at 127°F [53°C]. A heat pump is used to lower the temperature of the cooling water, while using the heat extracted to increase the temperature of process water used elsewhere in the plant. The heat pump consists of an evaporator, compressor, condenser, and expansion valve. In the evaporator, energy is transferred from the waste heat source to the refrigerant. Then the refrigerant enters the compressor, where its temperature increases. Superheated refrigerant then enters the condenser and transfers heat to the heat sink. Finally, refrigerant is throttled in an expansion valve before returning to the evaporator. 3.3.2.7 Open Cycle Vapor Recompression These systems use compression to increase the pressure (and consequently the temperature) of waste vapor. Mechanical vapor recompression (MVR) uses a mechanical compressor, while thermal vapor recompression (TVR) uses a steam ejector, and therefore is heatdriven rather than mechanically driven. 23 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |