PDF Publication Title:

Text from PDF Page: 051

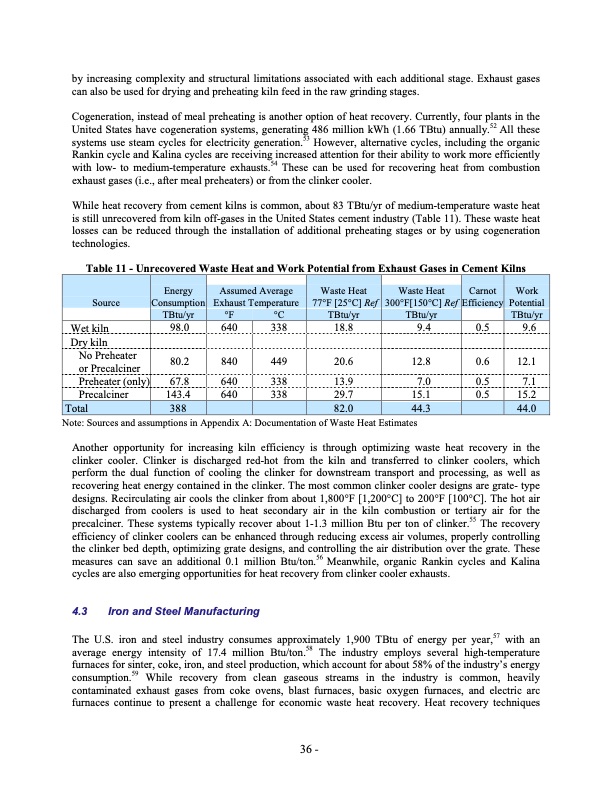

by increasing complexity and structural limitations associated with each additional stage. Exhaust gases can also be used for drying and preheating kiln feed in the raw grinding stages. Cogeneration, instead of meal preheating is another option of heat recovery. Currently, four plants in the United States have cogeneration systems, generating 486 million kWh (1.66 TBtu) annually.52 All these systems use steam cycles for electricity generation.53 However, alternative cycles, including the organic Rankin cycle and Kalina cycles are receiving increased attention for their ability to work more efficiently with low to mediumtemperature exhausts.54 These can be used for recovering heat from combustion exhaust gases (i.e., after meal preheaters) or from the clinker cooler. While heat recovery from cement kilns is common, about 83 TBtu/yr of mediumtemperature waste heat is still unrecovered from kiln offgases in the United States cement industry (Table 11). These waste heat losses can be reduced through the installation of additional preheating stages or by using cogeneration technologies. Table 11 Unrecovered Waste Heat and Work Potential from Exhaust Gases in Cement Kilns Source Energy Consumption Assumed Average Exhaust Temperature Waste Heat 77°F [25°C] Ref Waste Heat 300°F[150°C] Ref Carnot Efficiency Work Potential TBtu/yr °F °C TBtu/yr TBtu/yr TBtu/yr Wet kiln Dry kiln No Preheater or Precalciner Preheater (only) Precalciner 98.0 640 338 18.8 80.2 840 449 20.6 67.8 640 338 13.9 143.4 640 338 29.7 9.4 0.5 9.6 12.8 0.6 12.1 7.0 0.5 7.1 15.1 0.5 15.2 Total 388 82.0 44.3 44.0 Note: Sources and assumptions in Appendix A: Documentation of Waste Heat Estimates Another opportunity for increasing kiln efficiency is through optimizing waste heat recovery in the clinker cooler. Clinker is discharged redhot from the kiln and transferred to clinker coolers, which perform the dual function of cooling the clinker for downstream transport and processing, as well as recovering heat energy contained in the clinker. The most common clinker cooler designs are grate type designs. Recirculating air cools the clinker from about 1,800°F [1,200°C] to 200°F [100°C]. The hot air discharged from coolers is used to heat secondary air in the kiln combustion or tertiary air for the precalciner. These systems typically recover about 11.3 million Btu per ton of clinker.55 The recovery efficiency of clinker coolers can be enhanced through reducing excess air volumes, properly controlling the clinker bed depth, optimizing grate designs, and controlling the air distribution over the grate. These measures can save an additional 0.1 million Btu/ton.56 Meanwhile, organic Rankin cycles and Kalina cycles are also emerging opportunities for heat recovery from clinker cooler exhausts. 4.3 Iron and Steel Manufacturing The U.S. iron and steel industry consumes approximately 1,900 TBtu of energy per year,57 with an average energy intensity of 17.4 million Btu/ton.58 The industry employs several hightemperature furnaces for sinter, coke, iron, and steel production, which account for about 58% of the industry’s energy consumption.59 While recovery from clean gaseous streams in the industry is common, heavily contaminated exhaust gases from coke ovens, blast furnaces, basic oxygen furnaces, and electric arc furnaces continue to present a challenge for economic waste heat recovery. Heat recovery techniques 36 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |