PDF Publication Title:

Text from PDF Page: 055

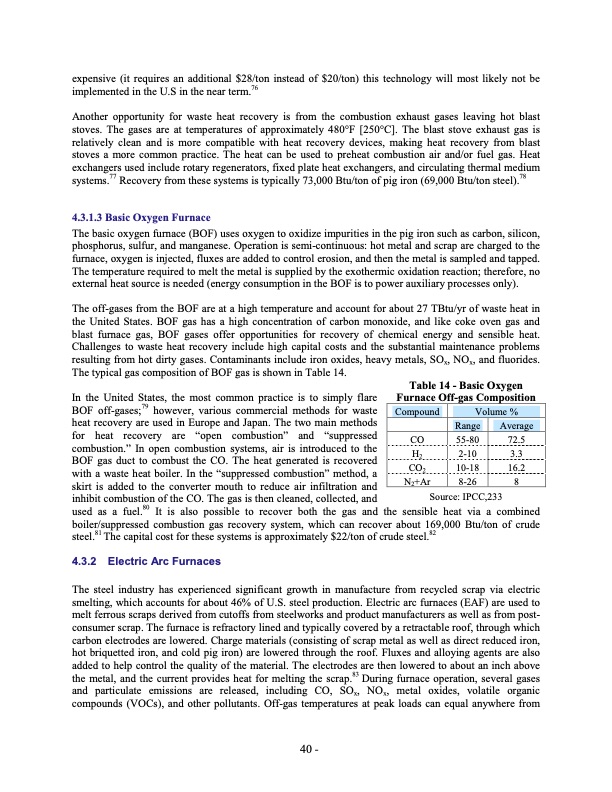

expensive (it requires an additional $28/ton instead of $20/ton) this technology will most likely not be implemented in the U.S in the near term.76 Another opportunity for waste heat recovery is from the combustion exhaust gases leaving hot blast stoves. The gases are at temperatures of approximately 480°F [250°C]. The blast stove exhaust gas is relatively clean and is more compatible with heat recovery devices, making heat recovery from blast stoves a more common practice. The heat can be used to preheat combustion air and/or fuel gas. Heat exchangers used include rotary regenerators, fixed plate heat exchangers, and circulating thermal medium systems.77 Recovery from these systems is typically 73,000 Btu/ton of pig iron (69,000 Btu/ton steel).78 4.3.1.3 Basic Oxygen Furnace The basic oxygen furnace (BOF) uses oxygen to oxidize impurities in the pig iron such as carbon, silicon, phosphorus, sulfur, and manganese. Operation is semicontinuous: hot metal and scrap are charged to the furnace, oxygen is injected, fluxes are added to control erosion, and then the metal is sampled and tapped. The temperature required to melt the metal is supplied by the exothermic oxidation reaction; therefore, no external heat source is needed (energy consumption in the BOF is to power auxiliary processes only). The offgases from the BOF are at a high temperature and account for about 27 TBtu/yr of waste heat in the United States. BOF gas has a high concentration of carbon monoxide, and like coke oven gas and blast furnace gas, BOF gases offer opportunities for recovery of chemical energy and sensible heat. Challenges to waste heat recovery include high capital costs and the substantial maintenance problems resulting from hot dirty gases. Contaminants include iron oxides, heavy metals, SOx, NOx, and fluorides. The typical gas composition of BOF gas is shown in Table 14. CO H2 CO2 N2+Ar The steel industry has experienced significant growth in manufacture from recycled scrap via electric smelting, which accounts for about 46% of U.S. steel production. Electric arc furnaces (EAF) are used to melt ferrous scraps derived from cutoffs from steelworks and product manufacturers as well as from post consumer scrap. The furnace is refractory lined and typically covered by a retractable roof, through which carbon electrodes are lowered. Charge materials (consisting of scrap metal as well as direct reduced iron, hot briquetted iron, and cold pig iron) are lowered through the roof. Fluxes and alloying agents are also added to help control the quality of the material. The electrodes are then lowered to about an inch above the metal, and the current provides heat for melting the scrap.83 During furnace operation, several gases and particulate emissions are released, including CO, SOx, NOx, metal oxides, volatile organic compounds (VOCs), and other pollutants. Offgas temperatures at peak loads can equal anywhere from In the United States, the most common practice is to simply flare BOF offgases;79 however, various commercial methods for waste heat recovery are used in Europe and Japan. The two main methods for heat recovery are “open combustion” and “suppressed combustion.” In open combustion systems, air is introduced to the BOF gas duct to combust the CO. The heat generated is recovered with a waste heat boiler. In the “suppressed combustion” method, a skirt is added to the converter mouth to reduce air infiltration and inhibit combustion of the CO. The gas is then cleaned, collected, and used as a fuel.80 It is also possible to recover both the gas and boiler/suppressed combustion gas recovery system, which can recover about 169,000 Btu/ton of crude steel.81 The capital cost for these systems is approximately $22/ton of crude steel.82 4.3.2 Electric Arc Furnaces Table 14 Basic Oxygen Furnace Offgas Composition Compound Volume % Range 5580 72.5 Average 210 3.3 1018 16.2 826 8 40 Source: IPCC,233 the sensible heat via a combinedPDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |