PDF Publication Title:

Text from PDF Page: 056

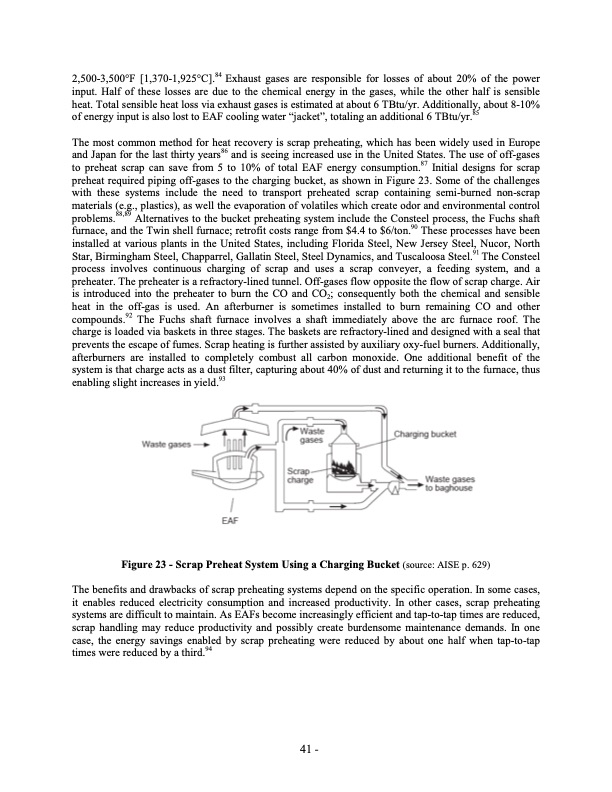

2,5003,500°F [1,3701,925°C].84 Exhaust gases are responsible for losses of about 20% of the power input. Half of these losses are due to the chemical energy in the gases, while the other half is sensible heat. Total sensible heat loss via exhaust gases is estimated at about 6 TBtu/yr. Additionally, about 810% of energy input is also lost to EAF cooling water “jacket”, totaling an additional 6 TBtu/yr.85 The most common method for heat recovery is scrap preheating, which has been widely used in Europe and Japan for the last thirty years86 and is seeing increased use in the United States. The use of offgases to preheat scrap can save from 5 to 10% of total EAF energy consumption.87 Initial designs for scrap preheat required piping offgases to the charging bucket, as shown in Figure 23. Some of the challenges with these systems include the need to transport preheated scrap containing semiburned nonscrap materials (e.g., plastics), as well the evaporation of volatiles which create odor and environmental control problems.88,89 Alternatives to the bucket preheating system include the Consteel process, the Fuchs shaft furnace, and the Twin shell furnace; retrofit costs range from $4.4 to $6/ton.90 These processes have been installed at various plants in the United States, including Florida Steel, New Jersey Steel, Nucor, North Star, Birmingham Steel, Chapparrel, Gallatin Steel, Steel Dynamics, and Tuscaloosa Steel.91 The Consteel process involves continuous charging of scrap and uses a scrap conveyer, a feeding system, and a preheater. The preheater is a refractorylined tunnel. Offgases flow opposite the flow of scrap charge. Air is introduced into the preheater to burn the CO and CO2; consequently both the chemical and sensible heat in the offgas is used. An afterburner is sometimes installed to burn remaining CO and other compounds.92 The Fuchs shaft furnace involves a shaft immediately above the arc furnace roof. The charge is loaded via baskets in three stages. The baskets are refractorylined and designed with a seal that prevents the escape of fumes. Scrap heating is further assisted by auxiliary oxyfuel burners. Additionally, afterburners are installed to completely combust all carbon monoxide. One additional benefit of the system is that charge acts as a dust filter, capturing about 40% of dust and returning it to the furnace, thus enabling slight increases in yield.93 Figure 23 Scrap Preheat System Using a Charging Bucket (source: AISE p. 629) The benefits and drawbacks of scrap preheating systems depend on the specific operation. In some cases, it enables reduced electricity consumption and increased productivity. In other cases, scrap preheating systems are difficult to maintain. As EAFs become increasingly efficient and taptotap times are reduced, scrap handling may reduce productivity and possibly create burdensome maintenance demands. In one case, the energy savings enabled by scrap preheating were reduced by about one half when taptotap times were reduced by a third.94 41 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |