PDF Publication Title:

Text from PDF Page: 058

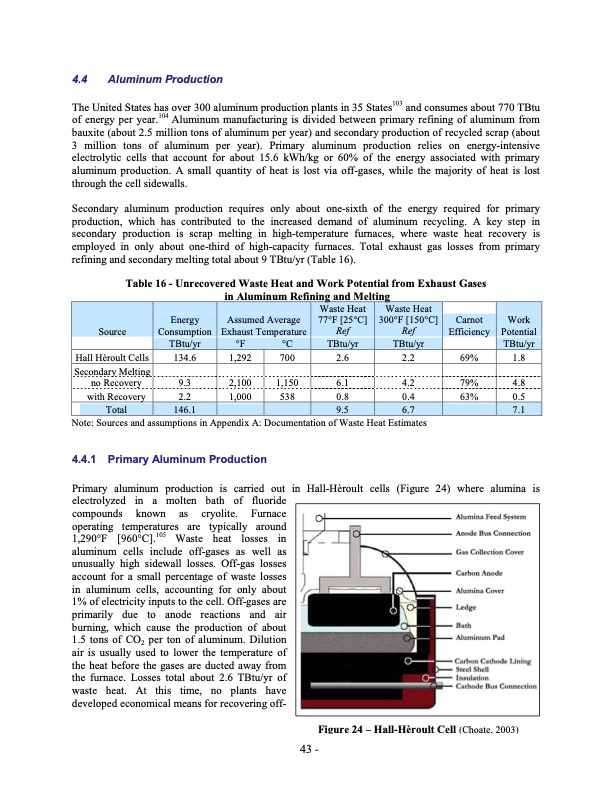

4.4 Aluminum Production The United States has over 300 aluminum production plants in 35 States103 and consumes about 770 TBtu of energy per year.104 Aluminum manufacturing is divided between primary refining of aluminum from bauxite (about 2.5 million tons of aluminum per year) and secondary production of recycled scrap (about 3 million tons of aluminum per year). Primary aluminum production relies on energyintensive electrolytic cells that account for about 15.6 kWh/kg or 60% of the energy associated with primary aluminum production. A small quantity of heat is lost via offgases, while the majority of heat is lost through the cell sidewalls. Secondary aluminum production requires only about onesixth of the energy required for primary production, which has contributed to the increased demand of aluminum recycling. A key step in secondary production is scrap melting in hightemperature furnaces, where waste heat recovery is employed in only about onethird of highcapacity furnaces. Total exhaust gas losses from primary refining and secondary melting total about 9 TBtu/yr (Table 16). Table 16 Unrecovered Waste Heat and Work Potential from Exhaust Gases in Aluminum Refining and Melting Source Energy Consumption Assumed Average Exhaust Temperature Waste Heat 77°F [25°C] Ref Waste Heat 300°F [150°C] Ref Carnot Efficiency Work Potential TBtu/yr °F °C TBtu/yr TBtu/yr TBtu/yr Hall Hèroult Cells Secondary Melting no Recovery with Recovery Note: Sources and assumptions in Appendix A: Documentation of Waste Heat Estimates 4.4.1 Primary Aluminum Production 134.6 1,292 700 9.3 2,100 1,150 2.6 2.2 6.1 4.2 69% 1.8 79% 4.8 63% 0.5 2.2 1,000 538 0.8 0.4 Total 146.1 9.5 6.7 7.1 Primary aluminum production is carried out in HallHèroult cells (Figure 24) where alumina is electrolyzed in a molten bath of fluoride compounds known as cryolite. Furnace operating temperatures are typically around 1,290°F [960°C].105 Waste heat losses in aluminum cells include offgases as well as unusually high sidewall losses. Offgas losses account for a small percentage of waste losses in aluminum cells, accounting for only about 1% of electricity inputs to the cell. Offgases are primarily due to anode reactions and air burning, which cause the production of about 1.5 tons of CO2 per ton of aluminum. Dilution air is usually used to lower the temperature of the heat before the gases are ducted away from the furnace. Losses total about 2.6 TBtu/yr of waste heat. At this time, no plants have developed economical means for recovering off Figure 24 – HallHèroult Cell (Choate, 2003) 43 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |