PDF Publication Title:

Text from PDF Page: 060

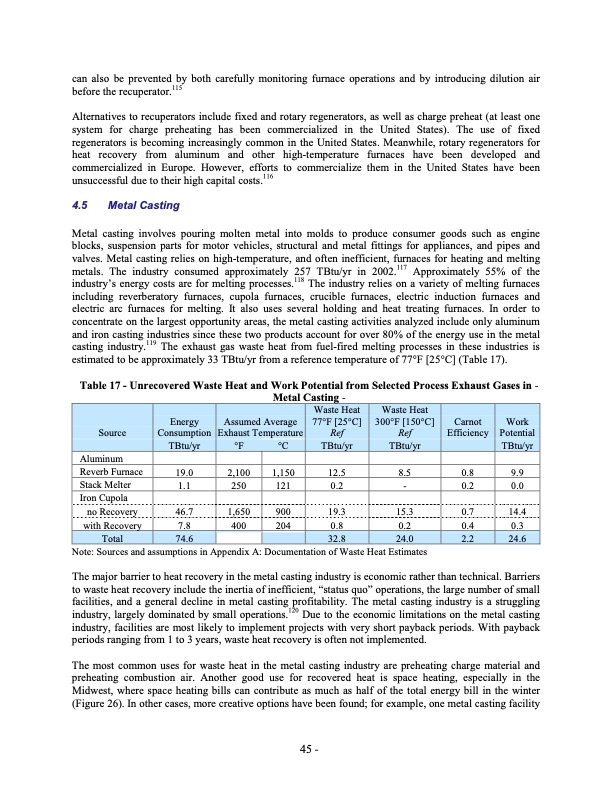

can also be prevented by both carefully monitoring furnace operations and by introducing dilution air before the recuperator.115 Alternatives to recuperators include fixed and rotary regenerators, as well as charge preheat (at least one system for charge preheating has been commercialized in the United States). The use of fixed regenerators is becoming increasingly common in the United States. Meanwhile, rotary regenerators for heat recovery from aluminum and other hightemperature furnaces have been developed and commercialized in Europe. However, efforts to commercialize them in the United States have been unsuccessful due to their high capital costs.116 4.5 Metal Casting Metal casting involves pouring molten metal into molds to produce consumer goods such as engine blocks, suspension parts for motor vehicles, structural and metal fittings for appliances, and pipes and valves. Metal casting relies on hightemperature, and often inefficient, furnaces for heating and melting metals. The industry consumed approximately 257 TBtu/yr in 2002.117 Approximately 55% of the industry’s energy costs are for melting processes.118 The industry relies on a variety of melting furnaces including reverberatory furnaces, cupola furnaces, crucible furnaces, electric induction furnaces and electric arc furnaces for melting. It also uses several holding and heat treating furnaces. In order to concentrate on the largest opportunity areas, the metal casting activities analyzed include only aluminum and iron casting industries since these two products account for over 80% of the energy use in the metal casting industry.119 The exhaust gas waste heat from fuelfired melting processes in these industries is estimated to be approximately 33 TBtu/yr from a reference temperature of 77°F [25°C] (Table 17). Table 17 Unrecovered Waste Heat and Work Potential from Selected Process Exhaust Gases in Metal Casting Source Energy Consumption Assumed Average Exhaust Temperature Waste Heat 77°F [25°C] Ref Waste Heat 300°F [150°C] Ref Carnot Efficiency Work Potential TBtu/yr °F °C TBtu/yr TBtu/yr TBtu/yr Aluminum Reverb Furnace Stack Melter Iron Cupola no Recovery with Recovery 19.0 2,100 1,150 12.5 8.5 1.1 250 121 0.2 46.7 1,650 900 19.3 15.3 7.8 400 204 0.8 0.2 0.8 9.9 0.2 0.0 0.7 14.4 0.4 0.3 Total 74.6 32.8 24.0 2.2 24.6 Note: Sources and assumptions in Appendix A: Documentation of Waste Heat Estimates The major barrier to heat recovery in the metal casting industry is economic rather than technical. Barriers to waste heat recovery include the inertia of inefficient, “status quo” operations, the large number of small facilities, and a general decline in metal casting profitability. The metal casting industry is a struggling industry, largely dominated by small operations.120 Due to the economic limitations on the metal casting industry, facilities are most likely to implement projects with very short payback periods. With payback periods ranging from 1 to 3 years, waste heat recovery is often not implemented. The most common uses for waste heat in the metal casting industry are preheating charge material and preheating combustion air. Another good use for recovered heat is space heating, especially in the Midwest, where space heating bills can contribute as much as half of the total energy bill in the winter (Figure 26). In other cases, more creative options have been found; for example, one metal casting facility 45 PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |