PDF Publication Title:

Text from PDF Page: 061

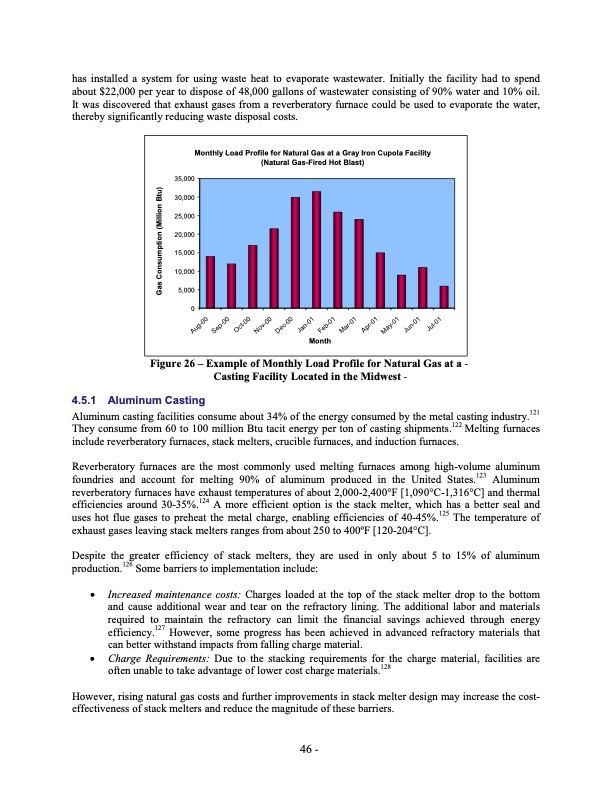

has installed a system for using waste heat to evaporate wastewater. Initially the facility had to spend about $22,000 per year to dispose of 48,000 gallons of wastewater consisting of 90% water and 10% oil. It was discovered that exhaust gases from a reverberatory furnace could be used to evaporate the water, thereby significantly reducing waste disposal costs. Figure 26 – Example of Monthly Load Profile for Natural Gas at a Casting Facility Located in the Midwest 4.5.1 Aluminum Casting Aluminum casting facilities consume about 34% of the energy consumed by the metal casting industry.121 They consume from 60 to 100 million Btu tacit energy per ton of casting shipments.122 Melting furnaces include reverberatory furnaces, stack melters, crucible furnaces, and induction furnaces. Reverberatory furnaces are the most commonly used melting furnaces among highvolume aluminum foundries and account for melting 90% of aluminum produced in the United States.123 Aluminum reverberatory furnaces have exhaust temperatures of about 2,0002,400°F [1,090°C1,316°C] and thermal efficiencies around 3035%.124 A more efficient option is the stack melter, which has a better seal and uses hot flue gases to preheat the metal charge, enabling efficiencies of 4045%.125 The temperature of exhaust gases leaving stack melters ranges from about 250 to 400oF [120204°C]. Despite the greater efficiency of stack melters, they are used in only about 5 to 15% of aluminum production.126 Some barriers to implementation include: • Increased maintenance costs: Charges loaded at the top of the stack melter drop to the bottom and cause additional wear and tear on the refractory lining. The additional labor and materials required to maintain the refractory can limit the financial savings achieved through energy efficiency.127 However, some progress has been achieved in advanced refractory materials that can better withstand impacts from falling charge material. • Charge Requirements: Due to the stacking requirements for the charge material, facilities are often unable to take advantage of lower cost charge materials.128 However, rising natural gas costs and further improvements in stack melter design may increase the cost effectiveness of stack melters and reduce the magnitude of these barriers. 35,000 30,000 25,000 20,000 15,000 10,000 5,000 0 Monthly Load Profile for Natural Gas at a Gray Iron Cupola Facility (Natural GasFired Hot Blast) Month 46 Gas Consumption (Million Btu) Aug00 Sep00 Oct00 Nov00 Dec00 Jan01 Feb01 Mar01 Apr01 May01 Jun01 Jul01PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |