PDF Publication Title:

Text from PDF Page: 062

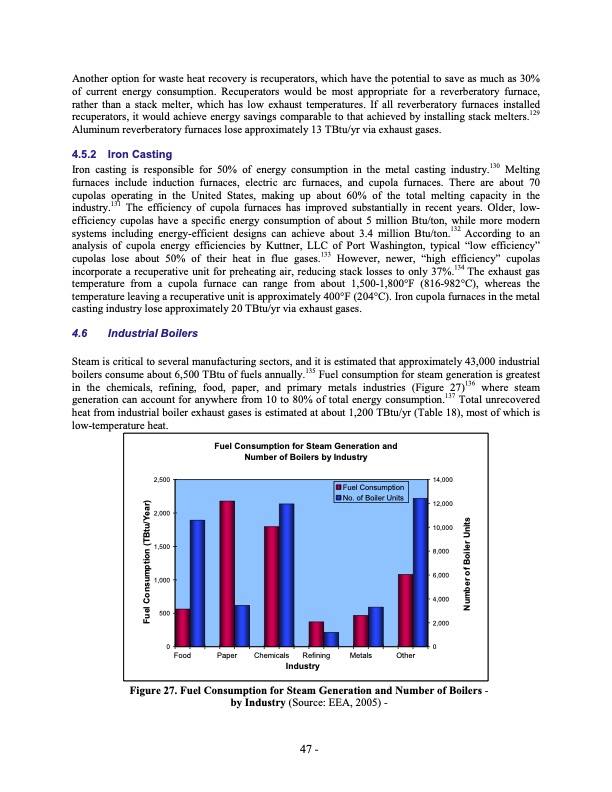

Another option for waste heat recovery is recuperators, which have the potential to save as much as 30% of current energy consumption. Recuperators would be most appropriate for a reverberatory furnace, rather than a stack melter, which has low exhaust temperatures. If all reverberatory furnaces installed recuperators, it would achieve energy savings comparable to that achieved by installing stack melters.129 Aluminum reverberatory furnaces lose approximately 13 TBtu/yr via exhaust gases. 4.5.2 Iron Casting Iron casting is responsible for 50% of energy consumption in the metal casting industry.130 Melting furnaces include induction furnaces, electric arc furnaces, and cupola furnaces. There are about 70 cupolas operating in the United States, making up about 60% of the total melting capacity in the industry.131 The efficiency of cupola furnaces has improved substantially in recent years. Older, low efficiency cupolas have a specific energy consumption of about 5 million Btu/ton, while more modern systems including energyefficient designs can achieve about 3.4 million Btu/ton.132 According to an analysis of cupola energy efficiencies by Kuttner, LLC of Port Washington, typical “low efficiency” cupolas lose about 50% of their heat in flue gases.133 However, newer, “high efficiency” cupolas incorporate a recuperative unit for preheating air, reducing stack losses to only 37%.134 The exhaust gas temperature from a cupola furnace can range from about 1,5001,800°F (816982°C), whereas the temperature leaving a recuperative unit is approximately 400°F (204°C). Iron cupola furnaces in the metal casting industry lose approximately 20 TBtu/yr via exhaust gases. 4.6 Industrial Boilers Steam is critical to several manufacturing sectors, and it is estimated that approximately 43,000 industrial boilers consume about 6,500 TBtu of fuels annually.135 Fuel consumption for steam generation is greatest in the chemicals, refining, food, paper, and primary metals industries (Figure 27)136 where steam generation can account for anywhere from 10 to 80% of total energy consumption.137 Total unrecovered heat from industrial boiler exhaust gases is estimated at about 1,200 TBtu/yr (Table 18), most of which is lowtemperature heat. Figure 27. Fuel Consumption for Steam Generation and Number of Boilers by Industry (Source: EEA, 2005) Fuel Consumption for Steam Generation and Number of Boilers by Industry 2,500 14,000 12,000 10,000 Fuel Consumption No. of Boiler Units 2,000 1,500 1,000 500 8,000 6,000 4,000 2,000 00 Food Paper Chemicals Refining Metals Other Industry 47 Fuel Consumption (TBtu/Year) Number of Boiler UnitsPDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |