PDF Publication Title:

Text from PDF Page: 096

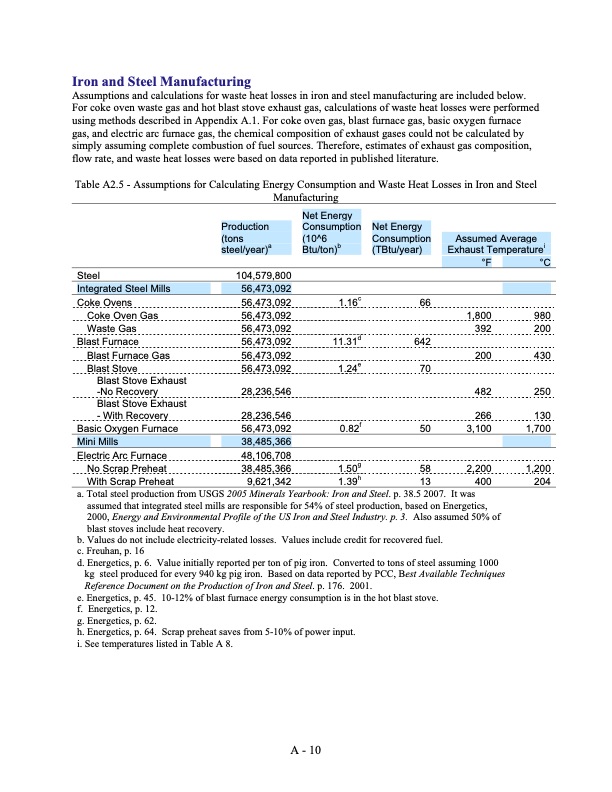

Iron and Steel Manufacturing Assumptions and calculations for waste heat losses in iron and steel manufacturing are included below. For coke oven waste gas and hot blast stove exhaust gas, calculations of waste heat losses were performed using methods described in Appendix A.1. For coke oven gas, blast furnace gas, basic oxygen furnace gas, and electric arc furnace gas, the chemical composition of exhaust gases could not be calculated by simply assuming complete combustion of fuel sources. Therefore, estimates of exhaust gas composition, flow rate, and waste heat losses were based on data reported in published literature. Table A2.5 - Assumptions for Calculating Energy Consumption and Waste Heat Losses in Iron and Steel Manufacturing Steel Integrated Steel Mills Coke Ovens Coke Oven Gas Waste Gas Blast Furnace Blast Furnace Gas Blast Stove Blast Stove Exhaust -No Recovery Blast Stove Exhaust - With Recovery Basic Oxygen Furnace Mini Mills Electric Arc Furnace No Scrap Preheat With Scrap Preheat Production (tons steel/year)a 104,579,800 56,473,092 56,473,092 56,473,092 56,473,092 56,473,092 56,473,092 56,473,092 28,236,546 28,236,546 56,473,092 38,485,366 48,106,708 38,485,366 9,621,342 Net Energy Consumption (10^6 Btu/ton)b 1.16c 11.31d 1.24e 0.82f 1.50g 1.39h Net Energy Consumption (TBtu/year) 66 642 70 50 58 13 Assumed Average Exhaust Temperaturei °F °C 1,800 980 392 200 200 430 482 250 266 130 3,100 1,700 2,200 1,200 400 204 a. Total steel production from USGS 2005 Minerals Yearbook: Iron and Steel. p. 38.5 2007. It was assumed that integrated steel mills are responsible for 54% of steel production, based on Energetics, 2000, Energy and Environmental Profile of the US Iron and Steel Industry. p. 3. Also assumed 50% of blast stoves include heat recovery. b. Values do not include electricity-related losses. Values include credit for recovered fuel. c. Freuhan, p. 16 d. Energetics, p. 6. Value initially reported per ton of pig iron. Converted to tons of steel assuming 1000 kg steel produced for every 940 kg pig iron. Based on data reported by PCC, Best Available Techniques Reference Document on the Production of Iron and Steel. p. 176. 2001. e. Energetics, p. 45. 10-12% of blast furnace energy consumption is in the hot blast stove. f. Energetics, p. 12. g. Energetics, p. 62. h. Energetics, p. 64. Scrap preheat saves from 5-10% of power input. i. See temperatures listed in Table A 8. A - 10PDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |