PDF Publication Title:

Text from PDF Page: 111

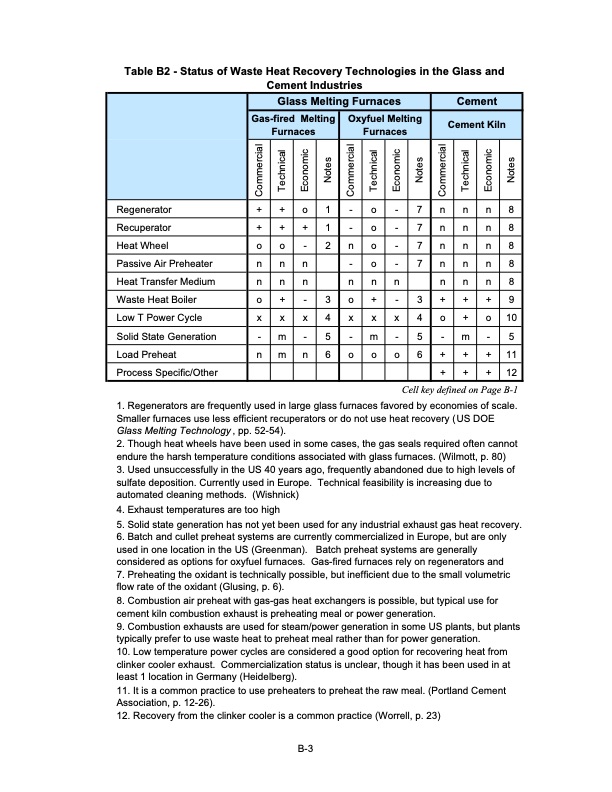

Table B2 Status of Waste Heat Recovery Technologies in the Glass and Cement Industries Glass Melting Furnaces Cement Gasfired Melting Furnaces Oxyfuel Melting Furnaces Cement Kiln Regenerator + + o 1 o 7 n n n 8 Recuperator + + + 1 o 7 n n n 8 Heat Wheel o o 2 n o 7 n n n 8 Passive Air Preheater n n n o 7 n n n 8 Heat Transfer Medium n n n n n n n n n 8 Waste Heat Boiler o + 3 o + 3 + + + 9 Low T Power Cycle x x x 4 x x x 4 o + o 10 Solid State Generation m 5 m 5 m 5 Load Preheat n m n 6 o o o 6 + + + 11 Process Specific/Other + + + 12 Cell key defined on Page B1 1. Regenerators are frequently used in large glass furnaces favored by economies of scale. Smaller furnaces use less efficient recuperators or do not use heat recovery (US DOE Glass Melting Technology , pp. 5254). 2. Though heat wheels have been used in some cases, the gas seals required often cannot endure the harsh temperature conditions associated with glass furnaces. (Wilmott, p. 80) 3. Used unsuccessfully in the US 40 years ago, frequently abandoned due to high levels of sulfate deposition. Currently used in Europe. Technical feasibility is increasing due to automated cleaning methods. (Wishnick) 4. Exhaust temperatures are too high 5. Solid state generation has not yet been used for any industrial exhaust gas heat recovery. 6. Batch and cullet preheat systems are currently commercialized in Europe, but are only used in one location in the US (Greenman). Batch preheat systems are generally considered as options for oxyfuel furnaces. Gasfired furnaces rely on regenerators and 7. Preheating the oxidant is technically possible, but inefficient due to the small volumetric flow rate of the oxidant (Glusing, p. 6). 8. Combustion air preheat with gasgas heat exchangers is possible, but typical use for cement kiln combustion exhaust is preheating meal or power generation. 9. Combustion exhausts are used for steam/power generation in some US plants, but plants typically prefer to use waste heat to preheat meal rather than for power generation. 10. Low temperature power cycles are considered a good option for recovering heat from clinker cooler exhaust. Commercialization status is unclear, though it has been used in at least 1 location in Germany (Heidelberg). 11. It is a common practice to use preheaters to preheat the raw meal. (Portland Cement Association, p. 1226). 12. Recovery from the clinker cooler is a common practice (Worrell, p. 23) B3 Commercial Technical Economic Notes Commercial Technical Economic Notes Commercial Technical Economic NotesPDF Image | Waste Heat to Energy Tech Opportunities in US Industry

PDF Search Title:

Waste Heat to Energy Tech Opportunities in US IndustryOriginal File Name Searched:

waste_heat_recovery.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |