PDF Publication Title:

Text from PDF Page: 019

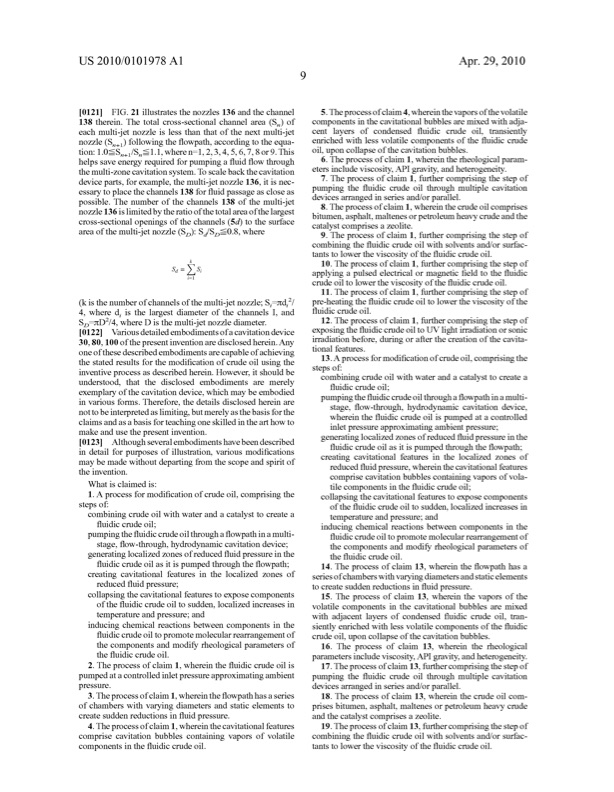

US 2010/0101978A1 Apr.29,2010 [0121] FIG.21illustratesthenozzles136andthechannel 138 therein. The total cross-sectional channel area (8,) of each multi-jet nozzle is less than that of the next multi-jet nozzle (SW1) following the ?oWpath, according to the equa tion:l.0§Sn+1/Sn§l.l,Wheren:l,2,3,4,5,6,7,8or9.This helps save energy required forpumping a ?uid ?oW through the multi-zone cavitation system. To scale back the cavitation device parts, for example, the multi-jet nozzle 136, it is nec essary to place the channels 138 for ?uid passage as close as possible. The number of the channels 138 of the multi-jet nozzle136islimitedbytheratioofthetotalareaofthelargest cross-sectional openings of the channels (5d) to the surface areaofthemulti-jetnozzle(SD):Sa/81320.8,Where (kisthenumberofchannelsofthemulti-jetnozzle;SZ-IJ'IZd7-2/ 4, Where dz. is the largest diameter of the channels I, and SD:J'|§D2/4,WhereD isthemulti-jetnozzlediameter. [0122] Variousdetailedembodimentsofacavitationdevice 30,80,100ofthepresentinventionaredisclosedherein.Any oneofthesedescribedembodiments arecapableofachieving the stated results for the modi?cation of crude oil using the inventive process as described herein. HoWever, it should be understood, that the disclosed embodiments are merely exemplary ofthe cavitation device, Which may be embodied in various forms. Therefore, the details disclosed herein are nottobeinterpretedaslimiting,butmerelyasthebasisforthe claimsandasabasisforteachingone skilledinthearthoW to make and use the present invention. [0123] Althoughseveralembodimentshavebeendescribed in detail for purposes of illustration, various modi?cations may be made Without departing from the scope and spiritof theinvention. What isclaimedis: 1.A processformodi?cationofcrudeoil,comprisingthe stepsof: combining crude oil With Water and a catalyst to create a ?uidiccrudeoil; pumpingthe?uidiccrudeoilthrougha?oWpathinamulti stage,?oW-through,hydrodynamiccavitationdevice; generating localized zones of reduced ?uid pressure in the ?uidic crude oil as itispumped through the ?oWpath; creating cavitational features in the localized zones of reduced ?uid pressure; collapsingthecavitationalfeaturestoexposecomponents of the ?uidic crude oil to sudden, localized increases in temperature and pressure; and inducing chemical reactions betWeen components in the ?uidiccrudeoiltopromotemolecularrearrangementof the components and modify rheological parameters of the ?uidic crude oil. 2. The process of claim 1, Wherein the ?uidic crude oil is pumped atacontrolledinletpressureapproximatingambient pressure. 3.Theprocessofclaim1,Whereinthe?oWpathhasaseries of chambers With varying diameters and static elements to create sudden reductions in ?uid pressure. 4.Theprocessofclaim1,Whereinthecavitationalfeatures comprise cavitation bubbles containing vapors of volatile components in the ?uidic crude oil. 5.Theprocessofclaim4,Whereinthevaporsofthevolatile components in the cavitational bubbles are mixed With adja cent layers of condensed ?uidic crude oil, transiently enriched With less volatile components of the ?uidic crude oil, upon collapse of the cavitation bubbles. 6. The process of claim 1, Wherein the rheological param eters include viscosity, API gravity, and heterogeneity. 7. The process of claim 1, further comprising the step of pumping the ?uidic crude oil through multiple cavitation devicesarrangedinseriesand/orparallel. 8.Theprocessofclaim1,Whereinthecrudeoilcomprises bitumen,asphalt,maltenesorpetroleumheavycrudeandthe catalyst comprises a zeolite. 9. The process of claim 1, further comprising the step of combining the ?uidic crude oil With solvents and/or surfac tants to loWer the viscosity of the ?uidic crude oil. 10. The process of claim 1, further comprising the step of applying a pulsed electrical or magnetic ?eld to the ?uidic crude oil to loWer the viscosity of the ?uidic crude oil. 11. The process of claim 1, further comprising the step of pre-heatingthe?uidiccrudeoiltoloWertheviscosityofthe ?uidic crude oil. 12. The process of claim 1, further comprising the step of exposingthe?uidiccrudeoiltoUV lightirradiationorsonic irradiation before, during or after the creation of the cavita tionalfeatures. 13.A processformodi?cationofcrudeoil,comprisingthe stepsof: combining crude oil With Water and a catalyst to create a ?uidiccrudeoil; pumpingthe?uidiccrudeoilthrougha?oWpathinamulti stage, ?oW-through, hydrodynamic cavitation device, Wherein the ?uidic crude oil is pumped at a controlled inletpressureapproximatingambientpressure; generating localized zones of reduced ?uid pressure in the ?uidic crude oil as itispumped through the ?oWpath; creating cavitational features in the localized zones of reduced?uidpressure,Whereinthecavitationalfeatures comprise cavitation bubbles containing vapors of vola tile components in the ?uidic crude oil; collapsing the cavitational features to expose components of the ?uidic crude oil to sudden, localized increases in temperature and pressure; and inducing chemical reactions betWeen components in the ?uidiccrudeoiltopromotemolecularrearrangementof the components and modify rheological parameters of the ?uidic crude oil. 14. The process of claim 13, Wherein the ?oWpath has a seriesofchambersWithvaryingdiametersandstaticelements to create sudden reductions in ?uid pressure. 15. The process of claim 13, Wherein the vapors of the volatile components in the cavitational bubbles are mixed With adjacent layers of condensed ?uidic crude oil, tran siently enriched With less volatile components of the ?uidic crude oil, upon collapse of the cavitation bubbles. 16. The process of claim 13, Wherein the rheological parametersincludeviscosity,APIgravity,andheterogeneity. 17.Theprocessofclaim13,furthercomprisingthestepof pumping the ?uidic crude oil through multiple cavitation devicesarrangedinseriesand/orparallel. 18. The process of claim 13, Wherein the crude oil com prisesbitumen,asphalt,maltenesorpetroleumheavycrude and the catalyst comprises a zeolite. 19.Theprocessofclaim13,furthercomprisingthestepof combining the ?uidic crude oil With solvents and/or surfac tants to loWer the viscosity of the ?uidic crude oil.PDF Image | FLOW THROUGH CAVITATION ASSISTED

PDF Search Title:

FLOW THROUGH CAVITATION ASSISTEDOriginal File Name Searched:

US20100101978.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |