PDF Publication Title:

Text from PDF Page: 004

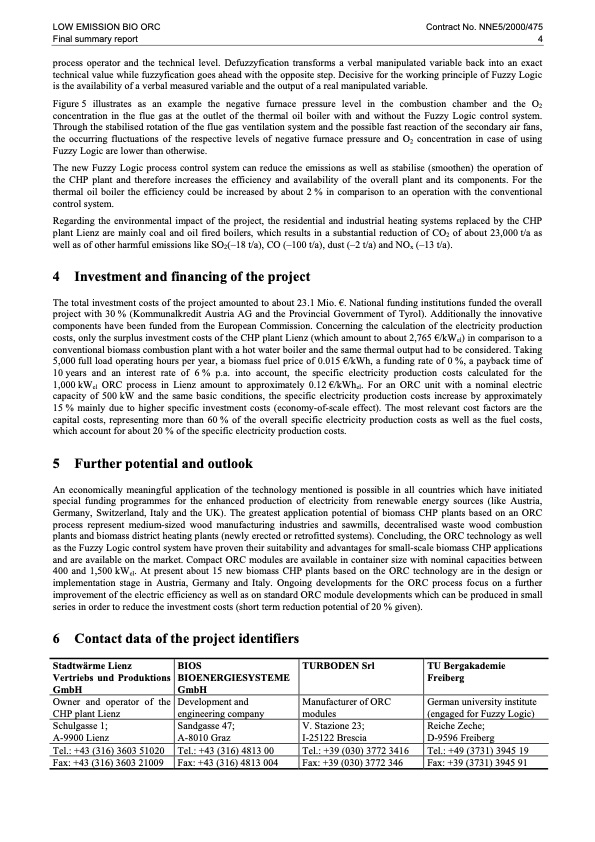

LOW EMISSION BIO ORC Contract No. NNE5/2000/475 Final summary report 4 process operator and the technical level. Defuzzyfication transforms a verbal manipulated variable back into an exact technical value while fuzzyfication goes ahead with the opposite step. Decisive for the working principle of Fuzzy Logic is the availability of a verbal measured variable and the output of a real manipulated variable. Figure 5 illustrates as an example the negative furnace pressure level in the combustion chamber and the O2 concentration in the flue gas at the outlet of the thermal oil boiler with and without the Fuzzy Logic control system. Through the stabilised rotation of the flue gas ventilation system and the possible fast reaction of the secondary air fans, the occurring fluctuations of the respective levels of negative furnace pressure and O2 concentration in case of using Fuzzy Logic are lower than otherwise. The new Fuzzy Logic process control system can reduce the emissions as well as stabilise (smoothen) the operation of the CHP plant and therefore increases the efficiency and availability of the overall plant and its components. For the thermal oil boiler the efficiency could be increased by about 2 % in comparison to an operation with the conventional control system. Regarding the environmental impact of the project, the residential and industrial heating systems replaced by the CHP plant Lienz are mainly coal and oil fired boilers, which results in a substantial reduction of CO2 of about 23,000 t/a as well as of other harmful emissions like SO2(–18 t/a), CO (–100 t/a), dust (–2 t/a) and NOx (–13 t/a). 4 Investment and financing of the project The total investment costs of the project amounted to about 23.1 Mio. €. National funding institutions funded the overall project with 30 % (Kommunalkredit Austria AG and the Provincial Government of Tyrol). Additionally the innovative components have been funded from the European Commission. Concerning the calculation of the electricity production costs, only the surplus investment costs of the CHP plant Lienz (which amount to about 2,765 €/kWel) in comparison to a conventional biomass combustion plant with a hot water boiler and the same thermal output had to be considered. Taking 5,000 full load operating hours per year, a biomass fuel price of 0.015 €/kWh, a funding rate of 0 %, a payback time of 10 years and an interest rate of 6 % p.a. into account, the specific electricity production costs calculated for the 1,000 kWel ORC process in Lienz amount to approximately 0.12 €/kWhel. For an ORC unit with a nominal electric capacity of 500 kW and the same basic conditions, the specific electricity production costs increase by approximately 15 % mainly due to higher specific investment costs (economy-of-scale effect). The most relevant cost factors are the capital costs, representing more than 60 % of the overall specific electricity production costs as well as the fuel costs, which account for about 20 % of the specific electricity production costs. 5 Further potential and outlook An economically meaningful application of the technology mentioned is possible in all countries which have initiated special funding programmes for the enhanced production of electricity from renewable energy sources (like Austria, Germany, Switzerland, Italy and the UK). The greatest application potential of biomass CHP plants based on an ORC process represent medium-sized wood manufacturing industries and sawmills, decentralised waste wood combustion plants and biomass district heating plants (newly erected or retrofitted systems). Concluding, the ORC technology as well as the Fuzzy Logic control system have proven their suitability and advantages for small-scale biomass CHP applications and are available on the market. Compact ORC modules are available in container size with nominal capacities between 400 and 1,500 kWel. At present about 15 new biomass CHP plants based on the ORC technology are in the design or implementation stage in Austria, Germany and Italy. Ongoing developments for the ORC process focus on a further improvement of the electric efficiency as well as on standard ORC module developments which can be produced in small series in order to reduce the investment costs (short term reduction potential of 20 % given). 6 Contact data of the project identifiers Stadtwärme Lienz Vertriebs und Produktions GmbH Owner and operator of the CHP plant Lienz Schulgasse 1; A-9900 Lienz Tel.: +43 (316) 3603 51020 Fax: +43 (316) 3603 21009 BIOS BIOENERGIESYSTEME GmbH Development and engineering company Sandgasse 47; A-8010 Graz Tel.: +43 (316) 4813 00 Fax: +43 (316) 4813 004 TURBODEN Srl Manufacturer of ORC modules V. Stazione 23; I-25122 Brescia Tel.: +39 (030) 3772 3416 Fax: +39 (030) 3772 346 TU Bergakademie Freiberg German university institute (engaged for Fuzzy Logic) Reiche Zeche; D-9596 Freiberg Tel.: +49 (3731) 3945 19 Fax: +39 (3731) 3945 91PDF Image | FUZZY LOGIC CONTROLLED CHP PLANT FOR BIOMASS FUELS

PDF Search Title:

FUZZY LOGIC CONTROLLED CHP PLANT FOR BIOMASS FUELSOriginal File Name Searched:

nne5_475_2000.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |