PDF Publication Title:

Text from PDF Page: 009

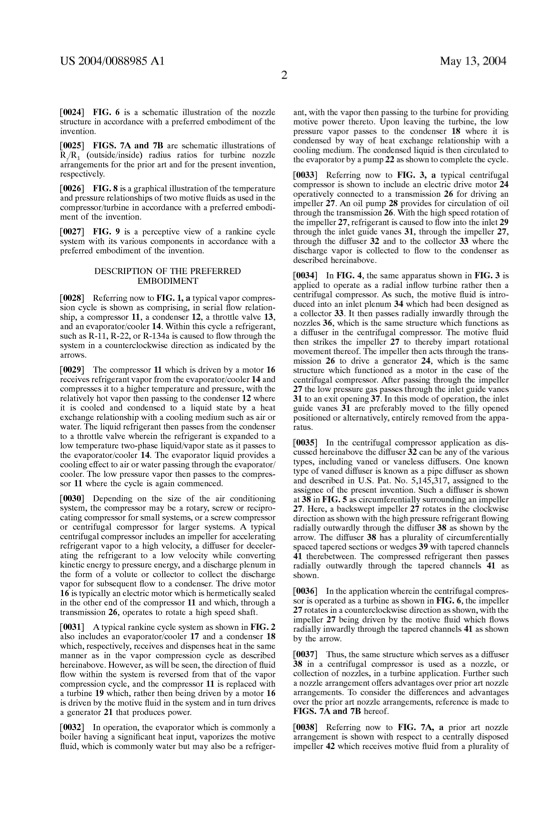

US 2004/0088985 A1 May 13,2004 [0024] FIG.6isaschematicillustrationofthenozzle ant,Withthevaporthenpassingtotheturbineforproviding structure in accordance With a preferred embodiment of the invention. [0025] FIGS.7Aand7Bareschematicillustrationsof RZ/R1 (outside/inside) radius ratios for turbine noZZle arrangements for the prior art and for the present invention, respectively. [0026] FIG.8isagraphicalillustrationofthetemperature and pressure relationships of tWo motive ?uids as used in the compressor/turbine in accordance With a preferred embodi ment of the invention. motive poWer thereto. Upon leaving the turbine, the loW pressure vapor passes to the condenser 18 Where it is condensed by Way of heat eXchange relationship With a cooling medium. The condensed liquid is then circulated to theevaporatorby apump 22 asshoWn tocomplete thecycle. [0033] ReferringnoWtoFIG.3,atypicalcentrifugal compressor is shoWn to include an electric drive motor 24 operatively connected to a transmission 26 for driving an impeller27.An oilpump 28providesforcirculationofoil throughthetransmission26.Withthehighspeedrotationof theimpeller27,refrigerantiscausedto?oW intotheinlet29 [0027] FIG.9isaperceptivevieWofarankinecycle throughtheinletguidevanes31,throughtheimpeller27, system With itsvarious components in accordance With a preferred embodiment of the invention. DESCRIPTION OF THE PREFERRED EMBODIMENT [0028] ReferringnoWtoFIG.1,atypicalvaporcompres sion cycle is shoWn as comprising, in serial ?oW relation ship, a compressor 11, a condenser 12, a throttle valve 13, and an evaporator/cooler 14. Within this cycle a refrigerant, suchasR-11,R-22,orR-134aiscausedto?oW throughthe system in a counterclockwise direction as indicated by the arroWs. through the diffuser 32 and to the collector 33 Where the discharge vapor is collected to ?oW to the condenser as described hereinabove. [0034] InFIG.4,thesameapparatusshoWninFIG.3is applied to operate as a radial in?oW turbine rather then a centrifugal compressor. As such, the motive ?uid is intro duced into an inlet plenum 34 Which had been designed as a collector 33. It then passes radially inWardly through the noZZles 36, Which is the same structure Which functions as a diffuser in the centrifugal compressor. The motive ?uid then strikes the impeller 27 to thereby impart rotational movement thereof. The impeller then acts through the trans mission 26 to drive a generator 24, Which is the same [0029] Thecompressor11Whichisdrivenbyamotor16 structureWhichfunctionedasamotorinthecaseofthe receivesrefrigerantvaporfromtheevaporator/cooler14and compresses itto a higher temperature and pressure, With the relatively hot vapor then passing to the condenser 12 Where it is cooled and condensed to a liquid state by a heat exchange relationship With a cooling medium such as air or Water. The liquid refrigerant then passes from the condenser to a throttle valve Wherein the refrigerant is expanded to a loW temperature tWo-phase liquid/vapor state as itpasses to the evaporator/cooler 14. The evaporator liquid provides a coolingeffecttoairorWaterpassingthroughtheevaporator/ cooler. The loW pressure vapor then passes to the compres sor 11 Where the cycle is again commenced. centrifugal compressor. After passing through the impeller 27 the loW pressure gas passes through the inlet guide vanes 31 to an eXit opening 37. In this mode of operation, the inlet guide vanes 31 are preferably moved to the ?lly opened positioned or alternatively, entirely removed from the appa ratus. [0035] Inthecentrifugalcompressorapplicationasdis cussed hereinabove the diffuser 32 can be any of the various types, including vaned or vaneless diffusers. One knoWn typeofvaneddiffuserisknoWn asapipediffuserasshoWn and described in US. Pat. No. 5,145,317, assigned to the assignee of the present invention. Such a diffuser is shoWn [0030] DependingonthesiZeoftheairconditioning at38inFIG.5ascircumferentiallysurroundinganimpeller system, the compressor may be a rotary, screW or recipro cating compressor for small systems, or a screW compressor or centrifugal compressor for larger systems. A typical centrifugalcompressorincludesanimpellerforaccelerating refrigerant vapor to a high velocity, a diffuser for deceler ating the refrigerant to a loW velocity While converting kinetic energy to pressure energy, and a discharge plenum in the form of a volute or collector to collect the discharge vapor for subsequent ?oW to a condenser. The drive motor 16 is typically an electric motor Which is hermetically sealed in the other end of the compressor 11 and Which, through a transmission 26, operates to rotate a high speed shaft. [0031] AtypicalrankinecyclesystemasshoWninFIG.2 also includes an evaporator/cooler 17 and a condenser 18 Which,respectively,receivesanddispensesheatinthesame manner as in the vapor compression cycle as described hereinabove. HoWever, as Will be seen, the direction of ?uid ?oW Within the system is reversed from that of the vapor compression cycle, and the compressor 11 is replaced With a turbine 19 Which, rather then being driven by a motor 16 is driven by the motive ?uid in the system and in turn drives a generator 21 that produces poWer. 27. Here, a backsWept impeller 27 rotates in the clockWise directionasshoWnWiththehighpressurerefrigerant?oWing radially outWardly through the diffuser 38 as shoWn by the arroW. The diffuser 38 has a plurality of circumferentially spacedtaperedsectionsorWedges39Withtaperedchannels 41 therebetWeen. The compressed refrigerant then passes radially outWardly through the tapered channels 41 as shoWn. [0036] IntheapplicationWhereinthecentrifugalcompres sor is operated as a turbine as shoWn in FIG. 6, the impeller 27 rotates in a counterclockWise direction as shoWn, With the impeller 27 being driven by the motive ?uid Which ?oWs radially inWardly through the tapered channels 41 as shoWn by the arroW. [0037] Thus,thesamestructureWhichservesasadiffuser 38 in a centrifugal compressor is used as a noZZle, or collection of noZZles, in a turbine application. Further such a noZZle arrangement offers advantages over prior art noZZle arrangements. To consider the differences and advantages over the prior art noZZle arrangements, reference is made to FIGS. 7A and 7B hereof. [0032] Inoperation,theevaporatorWhichiscommonlya [0038] ReferringnoWtoFIG.7A,apriorartnoZZle boiler having a signi?cant heat input, vaporiZes the motive arrangement is shoWn With respect to a centrally disposed ?uid, Which is commonly Water but may also be a refriger impeller 42 Which receives motive ?uid from a plurality ofPDF Image | ORGANIC RANKINE CYCLE WASTE HEAT APPLICATIONS

PDF Search Title:

ORGANIC RANKINE CYCLE WASTE HEAT APPLICATIONSOriginal File Name Searched:

US20040088985.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |