PDF Publication Title:

Text from PDF Page: 020

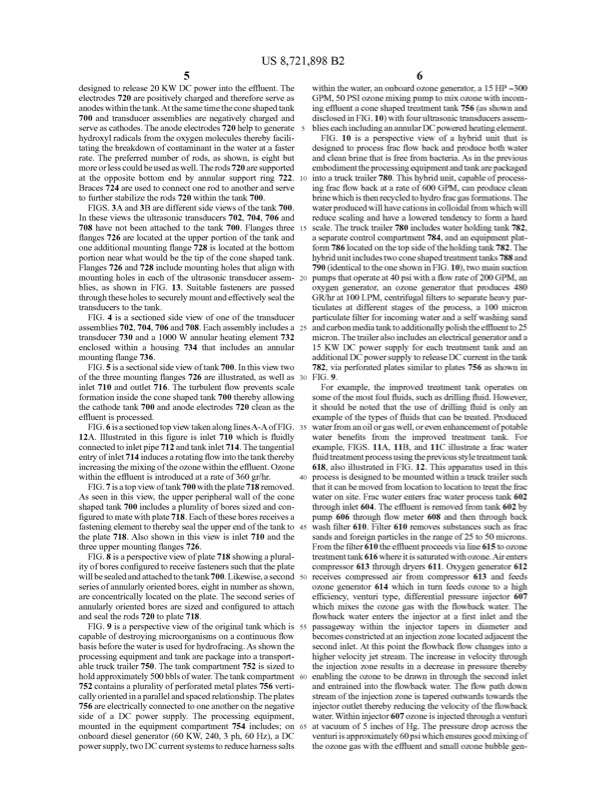

US 8,721,898B2 56 designedtorelease20KW DC powerintotheef?uent.The electrodes 720 are positively charged and therefore serve as anodes within the tank. At the same time the cone shaped tank 700 and transducer assemblies are negatively charged and serve as cathodes. The anode electrodes 720 help to generate hydroxylradicalsfromtheoxygenmoleculestherebyfacili tating the breakdown of contaminant in the water at a faster rate. The preferred number of rods, as shown, is eight but more or less could be used as well. The rods 720 are supported at the opposite bottom end by annular support ring 722. Braces 724 are used to connect one rod to another and serve to further stabilize the rods 720 within the tank 700. FIGS.3A and3B aredifferentsideviewsofthetank700. In these views the ultrasonic transducers 702, 704, 706 and 708 have not been attached to the tank 700. Flanges three ?anges 726 are located at the upper portion of the tank and one additional mounting ?ange 728 is located at the bottom portion near what would be the tip of the cone shaped tank. Flanges 726 and 728 include mounting holes that align with mountingholesineachoftheultrasonictransducerassem 20 blies, as shown in FIG. 13. Suitable fasteners are passed throughtheseholestosecurelymountandeffectivelysealthe transducers to the tank. withinthewater,anonboardozonegenerator,a15HP —300 GPM, 50PSIozonemixingpumptomixozonewithincom ing ef?uent a cone shaped treatment tank 756 (as shown and disclosed in FIG. 10) with four ultrasonic transducers assem blieseachincludinganannularDC poweredheatingelement. FIG. 10 is a perspective view of a hybrid unit that is designed to process frac ?ow back and produce both water andcleanbrinethatisfreefrombacteria.As intheprevious embodimenttheprocessingequipmentandtankarepackaged intoatrucktrailer780.Thishybridunit,capableofprocess ingfrac?owbackatarateof600GPM, canproduceclean brinewhichisthenrecycledtohydrofracgasformations.The waterproducedwillhavecationsincolloidalfromwhichwill reduce scaling and have a lowered tendency to form a hard scale. The truck trailer 780 includes water holding tank 782, a separate control compartment 784, and an equipment plat form 786 located on the top side of the holding tank 782. The hybrid unit includes two cone shaped treatment tanks 788 and 790 (identical to the one shown in FIG. 10), two main suction pumpsthatoperateat40psiwitha?owrateof200GPM,an oxygen generator, an ozone generator that produces 480 GR/hrat100LPM, centrifugal?lterstoseparateheavypar ticulates at different stages of the process, a 100 micron particulate ?lter for incoming water and a selfwashing sand andcarbonmediatanktoadditionallypolishthee?luentto25 micron. The traileralso includes an electrical generator and a FIG. 4 is a sectioned side view of one of the transducer assemblies702,704,706and708.Eachassemblyincludesa 25 transducer730anda1000W annularheatingelement732 enclosedwithinahousing734thatincludesanannular 15KWDCpowersupplyforeachtreatmenttankandan mounting?ange736. FIG. 5 isa sectional sideview oftank 700. Inthisview two ofthethreemounting?anges726areillustrated,aswellas 30 inlet 710 and outlet 716. The turbulent ?ow prevents scale formationinsidetheconeshapedtank700therebyallowing the cathode tank 700 and anode electrodes 720 clean as the e?luentisprocessed. FIG.6isasectionedtopviewtakenalonglinesA-AofFIG. 35 12A. Illustrated in this ?gure is inlet 710 which is ?uidly connectedtoinletpipe712andtankinlet714.Thetangential entryofinlet714 induces arotating?ow intothetankthereby increasingthemixingoftheozonewithinthee?luent.Ozone within the e?luent is introduced at a rate of 360 gr/hr. FIG.7isatopviewoftank700withtheplate718removed. As seeninthisview,theupperperipheralwallofthecone shaped tank 700 includes a plurality of bores sized and con ?gured to mate with plate 718. Each of these bores receives a fasteningelementtotherebysealtheupperendofthetankto45 the plate 718. Also shown in this view is inlet 710 and the threeuppermounting?anges726. FIG. 8 is a perspective view of plate 718 showing a plural ityofborescon?guredtoreceivefastenerssuchthattheplate willbesealedandattachedtothetank700.Likewise,asecond50 seriesofannularlyorientedbores,eightinnumberasshown, are concentrically located on the plate. The second series of annularly oriented bores are sized and con?gured to attach and seal the rods 720 to plate 718. FIG.9isaperspectiveviewoftheoriginaltankwhichis55 capable of destroying microorganisms on a continuous ?ow basisbeforethewaterisusedforhydrofracing.As shownthe processing equipment and tank are package into a transport able truck trailer 750. The tank compartment 752 is sized to holdapproximately500bblsofwater.Thetankcompartment 60 752 contains a plurality of perforated metal plates 756 verti callyorientedinaparallelandspacedrelationship.Theplates 756 are electrically connected to one another on the negative side of a DC power supply. The processing equipment, mountedintheequipmentcompartment754includes;on65 onboarddieselgenerator(60KW, 240,3ph,60Hz),aDC powersupply,twoDC currentsystemstoreduceharnesssalts additionalDC powersupplytoreleaseDC currentinthetank 782, via perforated plates similar to plates 756 as shown in FIG.9. For example, the improved treatment tank operates on some of the most foul ?uids, such as drilling ?uid. However, it should be noted that the use of drilling ?uid is only an example of the types of ?uids that can be treated. Produced waterfromanoilorgaswell,orevenenhancementofpotable water bene?ts from the improved treatment tank. For example, FIGS. 11A, 11B, and 11C illustrate a frac water ?uidtreatmentprocessusingthepreviousstyletreatmenttank 618, also illustrated in FIG. 12. This apparatus used in this process is designed to be mounted within a truck trailer such thatitcanbemoved fromlocationtolocationtotreatthefrac water on site. Frac water enters frac water process tank 602 through inlet 604. The e?luent is removed from tank 602 by pump 606 through ?ow meter 608 and then through back wash?lter610.Filter610removessubstancessuchasfrac sands and foreign particles in the range of 25 to 50 microns. From the ?lter 610 the e?luent proceeds via line 615 to ozone treatment tank 616 where itis saturated with ozone. Air enters compressor 613 through dryers 611. Oxygen generator 612 receivescompressedairfromcompressor613andfeeds ozone generator 614 which in turn feeds ozone to a high e?iciency, venturi type, differential pressure injector 607 which mixes the ozone gas with the ?owback water. The ?owback water enters the injector at a ?rst inlet and the passagewaywithintheinjectortapersindiameterand becomes constricted at an injection zone located adjacent the secondinlet.Atthispointthe?owback?ow changesintoa higher velocity jet stream. The increase in velocity through the injection zone results in a decrease in pressure thereby enablingtheozonetobedrawninthroughthesecondinlet and entrained into the ?owback water. The ?ow path down stream of the injection zone is tapered outwards towards the injectoroutlettherebyreducingthevelocityofthe?owback water. Within injector 607 ozone is injected through a venturi atvacuumof5inchesofHg.Thepressuredropacrossthe venturiisapproximately60psiwhichensuresgoodmixingof the ozone gas with the e?luent and small ozone bubble gen 40PDF Image | REACTOR TANK

PDF Search Title:

REACTOR TANKOriginal File Name Searched:

US8721898.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |