PDF Publication Title:

Text from PDF Page: 007

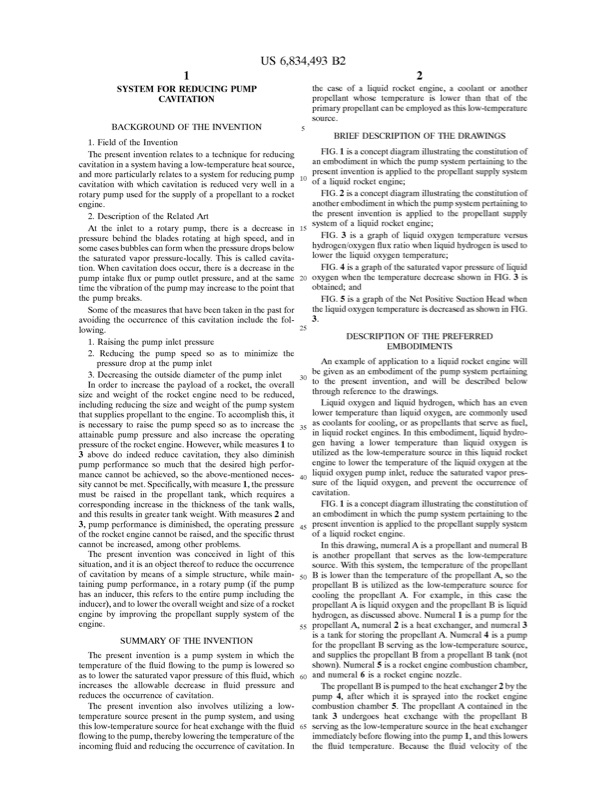

US 6,834,493 B2 12 SYSTEM FOR REDUCING PUMP CAVITATION BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates to a technique for reducing cavitation in a system having a loW-temperature heat source, and more particularly relates to a system for reducing pump cavitation With Which cavitation is reduced very Well in a rotary pump used for the supply of a propellant to a rocket engine. 2. Description of the Related Art 10 the case of a liquid rocket engine, a coolant or another propellant Whose temperature is loWer than that of the primary propellant can be employed as this loW-temperature source. BRIEF DESCRIPTION OF THE DRAWINGS FIG. 1 is a concept diagram illustrating the constitution of an embodiment in Which the pump system pertaining to the presentinventionisappliedtothepropellantsupplysystem ofaliquidrocketengine; FIG. 2 is a concept diagram illustrating the constitution of anotherembodimentinWhichthepump systempertainingto the present invention is applied to the propellant supply system of a liquid rocket engine; FIG. 3 is a graph of liquid oxygen temperature versus hydrogen/oxygen ?ux ratio When liquid hydrogen isused to loWer the liquid oxygen temperature; FIG. 4 is a graph of the saturated vapor pressure of liquid oxygen When the temperature decrease shoWn in FIG. 3 is obtained; and FIG. 5 is a graph of the Net Positive Suction Head When the liquid oxygen temperature isdecreased as shoWn in FIG. 3. DESCRIPTION OF THE PREFERRED EMBODIMENTS At the inlet to a rotary pump, there is a decrease in 15 pressure behind the blades rotating at high speed, and in some cases bubbles can form When the pressure drops beloW the saturated vapor pressure-locally. This is called cavita tion.When cavitationdoesoccur,thereisadecreaseinthe pump intake ?ux or pump outlet pressure, and at the same timethevibrationofthepump may increasetothepointthat the pump breaks. Some ofthemeasuresthathavebeentakeninthepastfor avoiding the occurrence of this cavitation include the fol loWing. 1.Raisingthepump inletpressure 2. Reducing the pump speed so as to minimize the pressure drop at the pump inlet 3.Decreasingtheoutsidediameterofthepump inlet In order to increase the payload of a rocket, the overall siZe and Weight of the rocket engine need to be reduced, including reducing the siZe and Weight of the pump system that supplies propellant to the engine. To accomplish this, it isnecessarytoraisethepumpspeedsoastoincreasethe35 attainable pump pressure and also increase the operating pressure of the rocket engine. HoWever, While measures 1 to 3 above do indeed reduce cavitation, they also diminish pump performance so much that the desired high perfor mancecannotbeachieved,sotheabove-mentionedneces 40 sity cannot be met. Speci?cally, With measure 1, the pressure must be raised in the propellant tank, Which requires a corresponding increase in the thickness of the tank Walls, and this results in greater tank Weight. With measures 2 and 3,pumpperformanceisdiminished,theoperatingpressure 45 of the rocket engine cannot be raised, and the speci?c thrust cannot be increased, among other problems. The present invention Was conceived in light of this situation, and itis an object thereof to reduce the occurrence of cavitation by means of a simple structure, While main taining pump performance, in a rotary pump (if the pump has an inducer, this refers to the entire pump including the inducer), and to loWer the overall Weight and siZe of a rocket enginebyimprovingthepropellantsupplysystemofthe engine. SUMMARY OF THE INVENTION The present invention is a pump system in Which the temperature of the ?uid ?oWing to the pump is loWered so as to loWer the saturated vapor pressure of this ?uid, Which increases the alloWable decrease in ?uid pressure and reduces the occurrence of cavitation. 55 An example of application to a liquid rocket engine Will be given as an embodiment of the pump system pertaining to the present invention, and Will be described beloW through reference to the draWings. Liquid oxygen and liquid hydrogen, Which has an even loWer temperature than liquid oxygen, are commonly used ascoolantsforcooling,oraspropellantsthatserveasfuel, in liquid rocket engines. In this embodiment, liquid hydro gen having a loWer temperature than liquid oxygen is utiliZed as the loW-temperature source in this liquid rocket engine to loWer the temperature of the liquid oxygen at the liquidoxygenpumpinlet,reducethesaturatedvaporpres sure of the liquid oxygen, and prevent the occurrence of cavitation. FIG. 1 is a concept diagram illustrating the constitution of an embodiment in Which the pump system pertaining to the presentinventionisappliedtothepropellantsupplysystem of a liquid rocket engine. InthisdraWing,numeralA isapropellantandnumeralB is another propellant that serves as the loW-temperature source. With this system, the temperature of the propellant B isloWerthanthetemperatureofthepropellantA,sothe propellant B is utiliZed as the loW-temperature source for cooling the propellant A. For example, in this case the propellantA isliquidoxygenandthepropellantB isliquid hydrogen,asdiscussedabove.Numeral1isapumpforthe propellantA,numeral2isaheatexchanger,andnumeral3 is a tank for storing the propellant A. Numeral 4 is a pump forthepropellantB servingastheloW-temperaturesource, and supplies the propellant B from a propellant B tank (not shoWn). Numeral 5 is a rocket engine combustion chamber, and numeral 6 is a rocket engine noZZle. The propellant B ispumped to the heat exchanger 2 by the pump 4, after Which it is sprayed into the rocket engine combustion chamber 5. The propellant A contained in the tank 3 undergoes heat exchange With the propellant B servingastheloW-temperaturesourceintheheatexchanger immediatelybefore?oWingintothepump 1,andthisloWers the ?uid temperature. Because the ?uid velocity of the The present invention also involves utiliZing a loW temperature source present in the pump system, and using thisloW-temperaturesourceforheatexchangeWiththe?uid 65 ?oWingtothepump,therebyloWeringthetemperatureofthe incoming ?uid and reducing the occurrence of cavitation. In 25PDF Image | SYSTEM FOR REDUCING PUMP CAVITATION

PDF Search Title:

SYSTEM FOR REDUCING PUMP CAVITATIONOriginal File Name Searched:

US6834493.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |