PDF Publication Title:

Text from PDF Page: 010

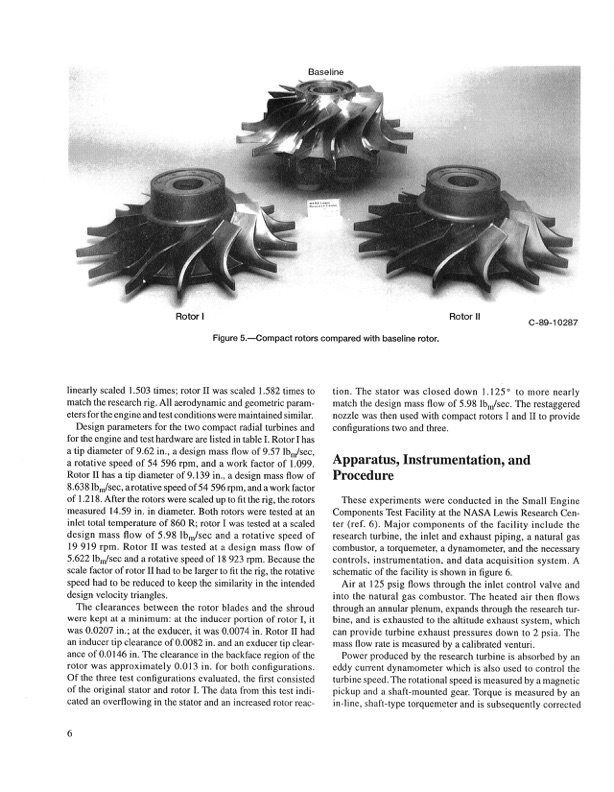

Rotor I ii_il)i!ill Figure 5.--Compact rotors compared with baseline rotor. Rotor II C-89-10287 linearly scaled 1.503 times; rotor II was scaled 1.582 times to match the research rig. All aerodynamic and geometric param- eters for the engine and test conditions were maintained similar, Design parameters for the two compact radial turbines and for the engine and test hardware are listed in table I. Rotor I has a tip diameter of 9.62 in., a design mass flow of 9.57 lbm/sec, a rotative speed of 54 596 rpm, and a work factor of 1.099. Rotor II has a tip diameter of 9.139 in., a design mass flow of 8.638 lbm/sec, a rotative speed of 54 596 rpm, and a work factor of 1.218. After the rotors were scaled up to fit the rig, the rotors measured 14.59 in. in diameter. Both rotors were tested at an inlet total temperature of 860 R; rotor I was tested at a scaled design mass flow of 5.98 lbm/sec and a rotative speed of 19 919 rpm. Rotor II was tested at a design mass flow of 5.622 lbm/sec and a rotative speed of 18 923 rpm. Because the scale factor of rotor II had to be larger to fit the rig, the rotative speed had to be reduced to keep the similarity in the intended design velocity triangles, The clearances between the rotor blades and the shroud were kept at a minimum: at the inducer portion of rotor I, it was 0.0207 in.; at the exducer, it was 0.0074 in. Rotor II had an inducer tip clearance of 0.0082 in. and an exducer tip clear- ance of 0.0146 in. The clearance in the backface region of the rotor was approximately 0.013 in. for both configurations, Of the three test configurations evaluated, the first consisted of the original stator and rotor I. The data from this test indi- cated an overflowing in the stator and an increased rotor reac- tion. The stator was closed down 1.125 o to more nearly match the design mass flow of 5.98 lbm/sec. The restaggered nozzle was then used with compact rotors I and II to provide configurations two and three. Apparatus, Instrumentation, and Procedure These experiments were conducted in the Small Engine Components Test Facility at the NASA Lewis Research Cen- ter (ref. 6). Major components of the facility include the research turbine, the inlet and exhaust piping, a natural gas combustor, a torquemeter, a dynamometer, and the necessary controls, instrumentation, and data acquisition system. A schematic of the facility is shown in figure 6. Air at 125 psig flows through the inlet control valve and into the natural gas combustor. The heated air then flows through an annular plenum, expands through the research tur- bine, and is exhausted to the altitude exhaust system, which can provide turbine exhaust pressures down to 2 psia. The mass flow rate is measured by a calibrated venturi. Power produced by the research turbine is absorbed by an eddy current dynamometer which is also used to control the turbine speed. The rotational speed is measured by a magnetic pickup and a shaft-mounted gear. Torque is measured by an in-line, shaft-type torquemeter and is subsequently corrected BaselinePDF Image | Aerodynamic Radial Inflow Turbine Rotors

PDF Search Title:

Aerodynamic Radial Inflow Turbine RotorsOriginal File Name Searched:

19960003236.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |