PDF Publication Title:

Text from PDF Page: 018

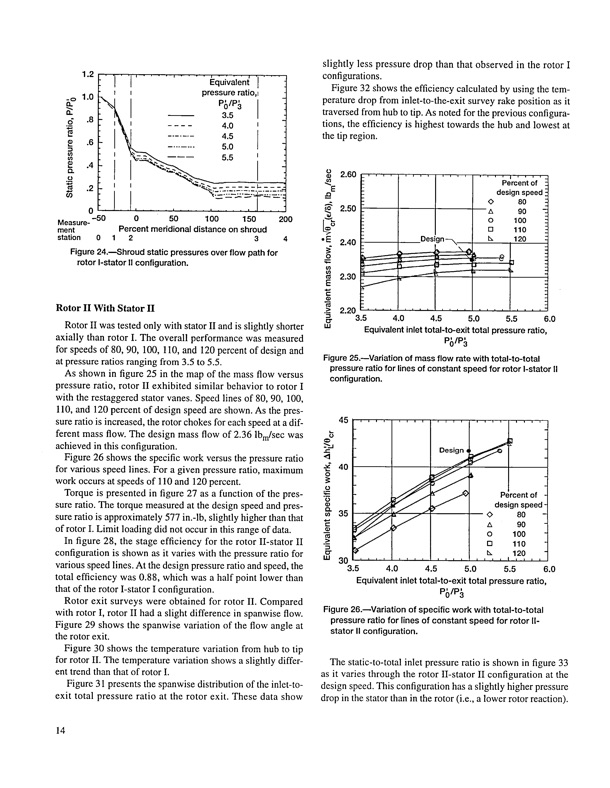

14 5o. _- ...... k 0 Measure-50 _" 2.50 200 I'_'_ A 90 0 1O0 [] 110 ment station 0 4 L_- •E 2.40 Design--_ Ix 120 1 1.2 1.0 .8 .6 .... _ , ......... , , - • - • Equivalent pressure ratio p(_/p_ 3.5 4.0 4.5 5.0 5.5 slightly less pressure drop than that observed in the rotor I configurations. Figure 32 shows the efficiency calculated by using the tem- perature drop from inlet-to-the-exit survey rake position as it traversed from hub to tip. As noted for the previous configura- tions, the efficiency is highest towards the hub and lowest at the tip region. = _ _ \ ....... .4 o -,_ _ Percenotf -_,_,_ ......... 0 50 1O0 150 Percentmeridionaldistanceon shroud 2 3 o 2.60 , ................ , .... 1 rotorI-statorII configuration. _ =_o 2.30_ __.__ j Figure24.--_Shroudstaticpressuresoverflow pathfor _ Rotor II With Stator II Rotor II was tested only with stator II and is slightly shorter axially than rotor I. The overall performance was measured for speeds of 80, 90, 100, 110, and 120 percent of design and at pressure ratios ranging from 3.5 to 5.5. As shown in figure 25 in the map of the mass flow versus pressure ratio, rotor II exhibited similar behavior to rotor I with the restaggered stator vanes. Speed lines of 80, 90, 100, 110, and 120 percent of design speed are shown. As the pres- sure ratio is increased, the rotor chokes for each speed at a dif- ferent mass flow. The design mass flow of 2.36 lbm/sec was achieved in this configuration. Figure 26 shows the specific work versus the pressure ratio for various speed lines. For a given pressure ratio, maximum work occurs at speeds of 110 and 120 percent. Torque is presented in figure 27 as a function of the pres- sure ratio. The torque measured at the design speed and pres- sure ratio is approximately 577 in.-lb, slightly higher than that of rotor I. Limit loading did not occur in this range of data. In figure 28, the stage efficiency for the rotor II-stator II configuration is shown as it varies with the pressure ratio for various speed lines. At the design pressure ratio and speed, the total efficiency was 0.88, which was a half point lower than that of the rotor I-stator I configuration, Rotor exit surveys were obtained for rotor II. Compared with rotor I, rotor II had a slight difference in spanwise flow. Figure 29 shows the spanwise variation of the flow angle at the rotor exit. Figure 30 shows the temperature variation from hub to tip for rotor II. The temperature variation shows a slightly differ- ent trend than that of rotor I. Figure 31 presents the spanwise distribution of the inlet-to- exit total pressure ratio at the rotor exit. These data show E ,£ .__ 2.20 "E_T tu _._-_ .................... 4.5 5.0 p_/p_ 3.5 4.0 Equivalent inlet total-to-exit total pressure ratio, Figure 25.--Variation of mass flow rate with total-to-total pressure ratio for lines of constant speed for rotor I-stator II ._ ._ tr o 100 configuration. 45 _ 40 o _ .o_ ._ _ _ 35 ////" b >- ,- _1 Design S" _ [] 110 Ix 120 ' .... .................... "' 30 ................ 3.5 4.0 _ _/ Percent of design speed 80 00 4.5 5.0 Equivalent inlet total-to-exit total pressure ratio, p6/p_ Figure 26.--Variation of specific work with total-to-total pressure ratio for lines of constant speed for rotor II- starer IIconfiguration. The static-to-total inlet pressure ratio is shown in figure 33 as it varies through the rotor II-stator II configuration at the design speed. This configuration has a slightly higher pressure drop in the stator than in the rotor (i.e., a lower rotor reaction). O 5.5 6.0 5.5 6.0PDF Image | Aerodynamic Radial Inflow Turbine Rotors

PDF Search Title:

Aerodynamic Radial Inflow Turbine RotorsOriginal File Name Searched:

19960003236.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |