PDF Publication Title:

Text from PDF Page: 006

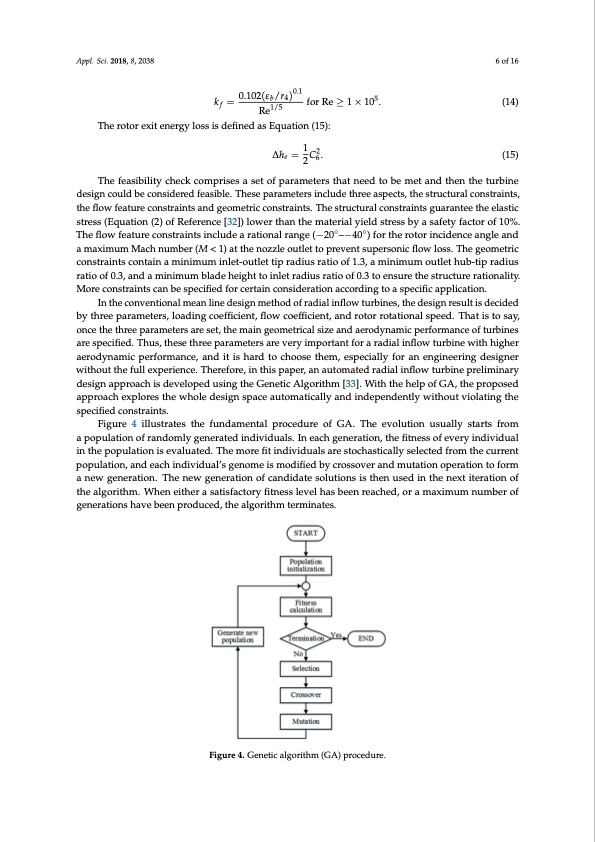

Appl. Sci. 2018, 8, 2038 6 of 16 0.102(εb/r4)0.1 5 forRe≥1×10. The rotor exit energy loss is defined as Equation (15): The feasibility check comprises a set of parameters that need to be met and then the turbine design could be considered feasible. These parameters include three aspects, the structural constraints, the flow feature constraints and geometric constraints. The structural constraints guarantee the elastic stress (Equation (2) of Reference [32]) lower than the material yield stress by a safety factor of 10%. The flow feature constraints include a rational range (−20◦–−40◦) for the rotor incidence angle and a maximum Mach number (M < 1) at the nozzle outlet to prevent supersonic flow loss. The geometric constraints contain a minimum inlet-outlet tip radius ratio of 1.3, a minimum outlet hub-tip radius ratio of 0.3, and a minimum blade height to inlet radius ratio of 0.3 to ensure the structure rationality. More constraints can be specified for certain consideration according to a specific application. In the conventional mean line design method of radial inflow turbines, the design result is decided by three parameters, loading coefficient, flow coefficient, and rotor rotational speed. That is to say, once the three parameters are set, the main geometrical size and aerodynamic performance of turbines are specified. Thus, these three parameters are very important for a radial inflow turbine with higher aerodynamic performance, and it is hard to choose them, especially for an engineering designer without the full experience. Therefore, in this paper, an automated radial inflow turbine preliminary design approach is developed using the Genetic Algorithm [33]. With the help of GA, the proposed approach explores the whole design space automatically and independently without violating the specified constraints. Figure 4 illustrates the fundamental procedure of GA. The evolution usually starts from a population of randomly generated individuals. In each generation, the fitness of every individual in the population is evaluated. The more fit individuals are stochastically selected from the current population, and each individual’s genome is modified by crossover and mutation operation to form a new generation. The new generation of candidate solutions is then used in the next iteration of the algorithm. When either a satisfactory fitness level has been reached, or a maximum number of Appl. Sci. 2018, 8, x FOR PEER REVIEW 7 of 17 generations have been produced, the algorithm terminates. Figure 4. Genetic algorithm (GA) procedure. Figure 4. Genetic algorithm (GA) procedure. Figure 5 shows the flowchart of the GA assisted radial inflow turbine preliminary design procedure. The GA drives the exploration of the design space defined by the loading coefficient, flow coefficient and rotational speed in a wide range. That is to say, the GA drives each new mean line design, and finally, when the convergence condition reaches requirements, the optimal result will be kf = Re1/5 ∆he = 12C62. (14) (15) obtained.PDF Image | Design and Optimization Approach for Radial Inflow Turbines

PDF Search Title:

Design and Optimization Approach for Radial Inflow TurbinesOriginal File Name Searched:

applsci-08-02038.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |