PDF Publication Title:

Text from PDF Page: 010

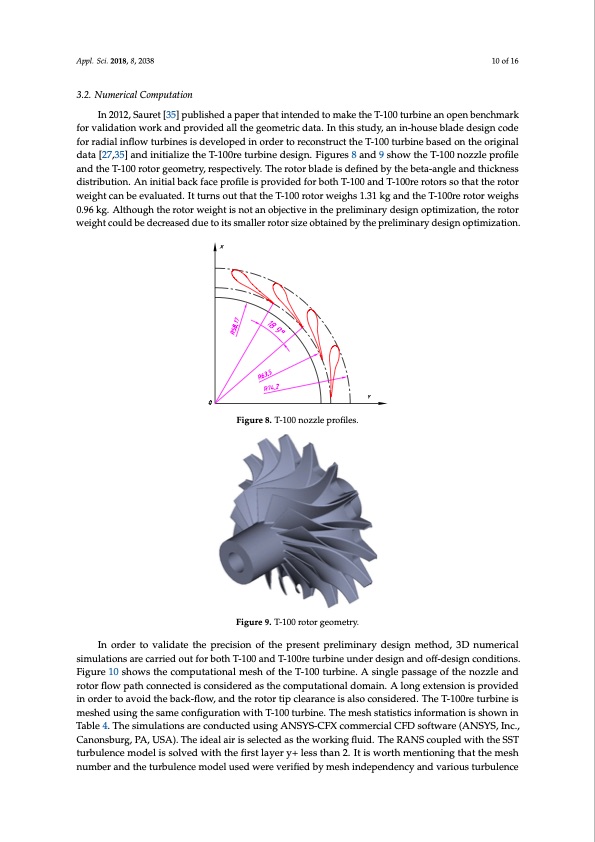

Therefore, the present automated preliminary design approach is quite effective to determine the main parameters for the preliminary design. In this approach, the GA helps the designer find the best combination of (ψ , φ , n ) corresponding to the highest total-to-static efficiency under specified constraints and well-established loss models in a short time, thus making a good start for the later 3D numerical optimization work, which will be presented in Part II of this paper [34]. Appl. Sci. 2018, 8, 2038 10 of 16 3.2. Numerical Computation 3.2. Numerical Computation In 2012, Sauret [35] published a paper that intended to make the T-100 turbine an open benchmark for validation work and provided all the geometric data. In this study, an in-house blade In 2012, Sauret [35] published a paper that intended to make the T-100 turbine an open benchmark design code for radial inflow turbines is developed in order to reconstruct the T-100 turbine based on for validation work and provided all the geometric data. In this study, an in-house blade design code the original data [27,35] and initialize the T-100re turbine design. Figures 8 and 9 show the T-100 for radial inflow turbines is developed in order to reconstruct the T-100 turbine based on the original nozzle profile and the T-100 rotor geometry, respectively. The rotor blade is defined by the beta-angle data [27,35] and initialize the T-100re turbine design. Figures 8 and 9 show the T-100 nozzle profile and thickness distribution. An initial back face profile is provided for both T-100 and T-100re rotors and the T-100 rotor geometry, respectively. The rotor blade is defined by the beta-angle and thickness so that the rotor weight can be evaluated. It turns out that the T-100 rotor weighs 1.31 kg and the T- distribution. An initial back face profile is provided for both T-100 and T-100re rotors so that the rotor 100re rotor weighs 0.96 kg. Although the rotor weight is not an objective in the preliminary design weight can be evaluated. It turns out that the T-100 rotor weighs 1.31 kg and the T-100re rotor weighs optimization, the rotor weight could be decreased due to its smaller rotor size obtained by the 0.96 kg. Although the rotor weight is not an objective in the preliminary design optimization, the rotor preliminary design optimization. weight could be decreased due to its smaller rotor size obtained by the preliminary design optimization. Appl. Sci. 2018, 8, x FOR PEER REVIEW Figure 8. T-100 nozzle profiles. Figure 8. T-100 nozzle profiles. 11 of 17 Figure 9. T-100 rotor geometry. Figure 9. T-100 rotor geometry. In order to validate the precision of the present preliminary design method, 3D numerical In order to validate the precision of the present preliminary design method, 3D numerical simulations are carried out for both T-100 and T-100re turbine under design and off-design conditions. simulations are carried out for both T-100 and T-100re turbine under design and off-design Figure 10 shows the computational mesh of the T-100 turbine. A single passage of the nozzle and conditions. Figure 10 shows the computational mesh of the T-100 turbine. A single passage of the rotor flow path connected is considered as the computational domain. A long extension is provided nozzle and rotor flow path connected is considered as the computational domain. A long extension in order to avoid the back-flow, and the rotor tip clearance is also considered. The T-100re turbine is is provided in order to avoid the back-flow, and the rotor tip clearance is also considered. The T-100re meshed using the same configuration with T-100 turbine. The mesh statistics information is shown in turbine is meshed using the same configuration with T-100 turbine. The mesh statistics information Table 4. The simulations are conducted using ANSYS-CFX commercial CFD software (ANSYS, Inc., is shown in Table 4. The simulations are conducted using ANSYS-CFX commercial CFD software Canonsburg, PA, USA). The ideal air is selected as the working fluid. The RANS coupled with the SST (ANSYS, Inc., Canonsburg, PA, USA). The ideal air is selected as the working fluid. The RANS turbulence model is solved with the first layer y+ less than 2. It is worth mentioning that the mesh coupled with the SST turbulence model is solved with the first layer y+ less than 2. It is worth number and the turbulence model used were verified by mesh independency and various turbulence mentioning that the mesh number and the turbulence model used were verified by mesh independency and various turbulence models provided in ANSYS-CFX, respectively. The details of verification can be found in Reference [19] published by our research group. The boundary conditions for validations are adopted using the design conditions in Table 1. It is noted that a modeling test was conducted with a T-100 turbine of a real geometry size (shown in Table 3), so the test boundary conditions are different from the design parameters. That is to say, thePDF Image | Design and Optimization Approach for Radial Inflow Turbines

PDF Search Title:

Design and Optimization Approach for Radial Inflow TurbinesOriginal File Name Searched:

applsci-08-02038.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |