PDF Publication Title:

Text from PDF Page: 001

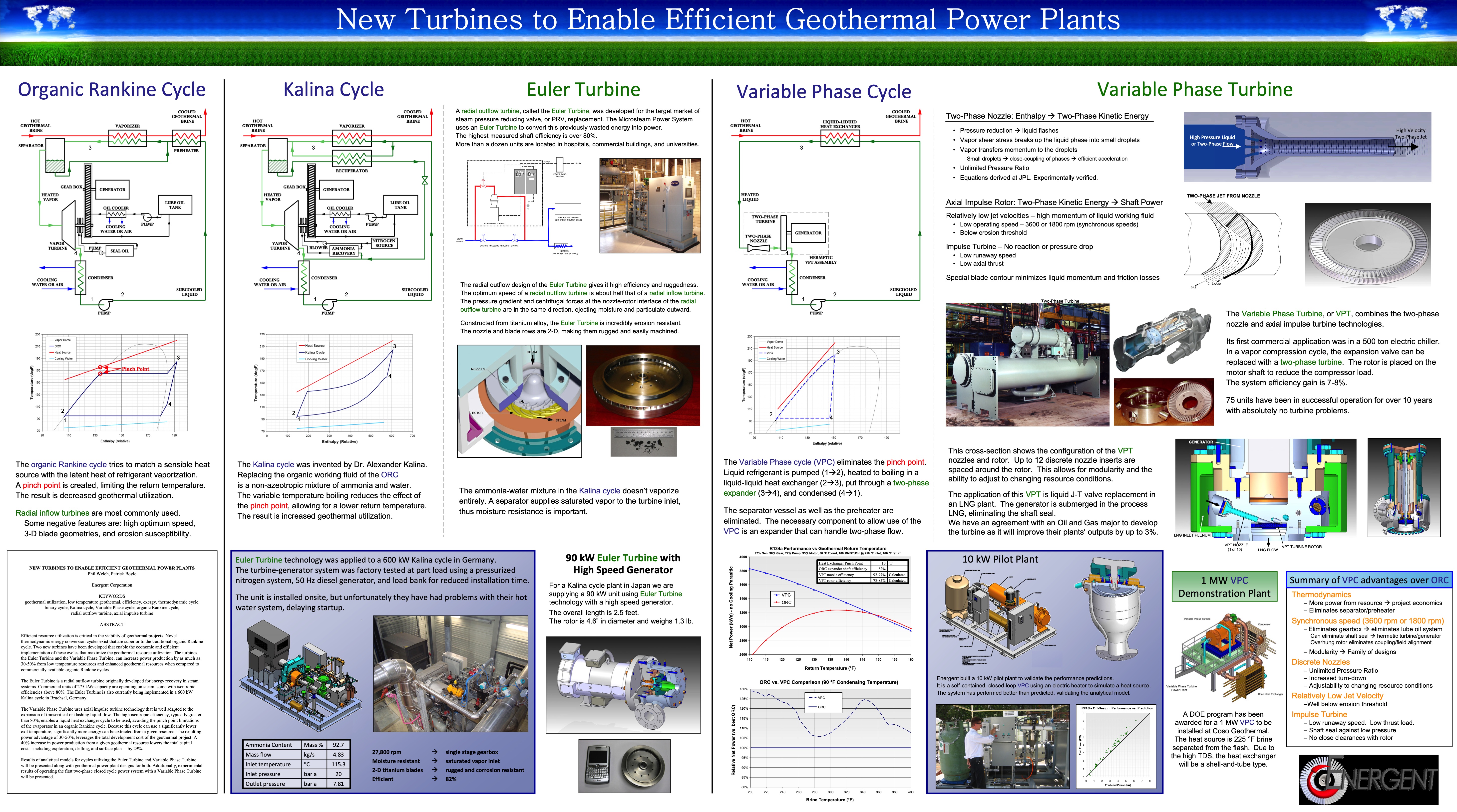

Relative Net Power (vs. best ORC) Net Power (kWe) - no Cooling Parasitic Test Power (kW) Organic Rankine Cycle Kalina Cycle Euler Turbine Variable Phase Cycle Variable Phase Turbine 2 1 2 1 2 1 4 3 3 More than a dozen units are located in hospitals, commercial buildings, and universities. 3 • Vapor shear stress breaks up the liquid phase into small droplets • Vapor transfers momentum to the droplets High Pressure Liquid or TwoPhase Flow The organic Rankine cycle tries to match a sensible heat source with the latent heat of refrigerant vaporization. A pinch point is created, limiting the return temperature. The result is decreased geothermal utilization. The Kalina cycle was invented by Dr. Alexander Kalina. Replacing the organic working fluid of the ORC is a non-azeotropic mixture of ammonia and water. The variable temperature boiling reduces the effect of the pinch point, allowing for a lower return temperature. The result is increased geothermal utilization. The Variable Phase cycle (VPC) eliminates the pinch point. Liquid refrigerant is pumped (1Æ2), heated to boiling in a liquid-liquid heat exchanger (2Æ3), put through a two-phase expander (3Æ4), and condensed (4Æ1). This cross-section shows the configuration of the VPT nozzles and rotor. Up to 12 discrete nozzle inserts are spaced around the rotor. This allows for modularity and the ability to adjust to changing resource conditions. Radial inflow turbines are most commonly used. Some negative features are: high optimum speed, 3-D blade geometries, and erosion susceptibility. The ammonia-water mixture in the Kalina cycle doesn’t vaporize entirely. A separator supplies saturated vapor to the turbine inlet, thus moisture resistance is important. The separator vessel as well as the preheater are eliminated. The necessary component to allow use of the VPC is an expander that can handle two-phase flow. The application of this VPT is liquid J-T valve replacement in an LNG plant. The generator is submerged in the process LNG, eliminating the shaft seal. We have an agreement with an Oil and Gas major to develop the turbine as it will improve their plants’ outputs by up to 3%. NEW TURBINES TO ENABLE EFFICIENT GEOTHERMAL POWER PLANTS 3800 Heat Exchanger Pinch Point ORC expander shaft efficiency VPT nozzle efficiency VPT rotor efficiency 10 °F 82% Phil Welch, Patrick Boyle Energent Corporation 92-97% Calculated 78-85% Calculated 1 MW VPC Demonstration Plant Summary of VPC advantages over ORC Thermodynamics KEYWORDS geothermal utilization, low temperature geothermal, efficiency, exergy, thermodynamic cycle, binary cycle, Kalina cycle, Variable Phase cycle, organic Rankine cycle, radial outflow turbine, axial impulse turbine The unit is installed onsite, but unfortunately they have had problems with their hot water system, delaying startup. 3400 VPC ABSTRACT Synchronous speed (3600 rpm or 1800 rpm) Efficient resource utilization is critical in the viability of geothermal projects. Novel thermodynamic energy conversion cycles exist that are superior to the traditional organic Rankine cycle. Two new turbines have been developed that enable the economic and efficient implementation of these cycles that maximize the geothermal resource utilization. The turbines, the Euler Turbine and the Variable Phase Turbine, can increase power production by as much as 30-50% from low temperature resources and enhanced geothermal resources when compared to commercially available organic Rankine cycles. 2800 The Euler Turbine is a radial outflow turbine originally developed for energy recovery in steam systems. Commercial units of 275 kWe capacity are operating on steam, some with isentropic efficiencies above 80%. The Euler Turbine is also currently being implemented in a 600 kW Kalina cycle in Bruchsal, Germany. ORC vs. VPC Comparison (90 °F Condensing Temperature) Energent built a 10 kW pilot plant to validate the performance predictions. It is a self-contained, closed-loop VPC using an electric heater to simulate a heat source. The system has performed better than predicted, validating the analytical model. – Unlimited Pressure Ratio – Increased turn-down – Adjustability to changing resource conditions The Variable Phase Turbine uses axial impulse turbine technology that is well adapted to the expansion of transcritical or flashing liquid flow. The high isentropic efficiency, typically greater than 80%, enables a liquid heat exchanger cycle to be used, avoiding the pinch point limitations of the evaporator in an organic Rankine cycle. Because this cycle can use a significantly lower exit temperature, significantly more energy can be extracted from a given resource. The resulting power advantage of 30-50%, leverages the total development cost of the geothermal project. A 40% increase in power production from a given geothermal resource lowers the total capital cost—including exploration, drilling, and surface plan— by 29%. ORC R245fa Off-Design: Performance vs. Prediction –Well below erosion threshold Results of analytical models for cycles utilizing the Euler Turbine and Variable Phase Turbine will be presented along with geothermal power plant designs for both. Additionally, experimental results of operating the first two-phase closed cycle power system with a Variable Phase Turbine will be presented. Æ saturated vapor inlet Æ 82% 95% 90% 85% Pinch Point 4 75 units have been in successful operation for over 10 years with absolutely no turbine problems. 3 Ammonia Content Mass flow Inlet temperature Inlet pressure Outlet pressure Mass % 92.7 kg/s 4.83 °C 115.3 bar a 20 bar a 7.81 27,800 rpm Æ single stage gearbox ��� �������� �� ������ ��������� ���������� ����� ������ 444 Impulse Turbine – No reaction or pressure drop • Low runaway speed • Low axial thrust 1 2 1 2 The radial outflow design of the Euler Turbine gives it high efficiency and ruggedness. The optimum speed of a radial outflow turbine is about half that of a radial inflow turbine. The pressure gradient and centrifugal forces at the nozzle-rotor interface of the radial outflow turbine are in the same direction, ejecting moisture and particulate outward. 1 2 Special blade contour minimizes liquid momentum and friction losses Two-Phase Turbine Euler Turbine technology was applied to a 600 kW Kalina cycle in Germany. The turbinegenerator system was factory tested at part load using a pressurized nitrogen system, 50 Hz diesel generator, and load bank for reduced installation time. 90 kW Euler Turbine with High Speed Generator 4000 10 kW Pilot Plant 4 3 Its first commercial application was in a 500 ton electric chiller. In a vapor compression cycle, the expansion valve can be replaced with a two-phase turbine. The rotor is placed on the motor shaft to reduce the compressor load. Moisture resistant 2D titanium blades Æ rugged and corrosion resistant Efficient 012345678 A radial outflow turbine, called the Euler Turbine, was developed for the target market of steam pressure reducing valve, or PRV, replacement. The Microsteam Power System uses an Euler Turbine to convert this previously wasted energy into power. The highest measured shaft efficiency is over 80%. Two-Phase Nozzle: EnthalpyÆTwo-Phase Kinetic Energy • Pressure reduction Æ liquid flashes High Velocity TwoPhase Jet Constructed from titanium alloy, the Euler Turbine is incredibly erosion resistant. The nozzle and blade rows are 2-D, making them rugged and easily machined. The Variable Phase Turbine, or VPT, combines the two-phase nozzle and axial impulse turbine technologies. For a Kalina cycle plant in Japan we are supplying a 90 kW unit using Euler Turbine technology with a high speed generator. 3600 The overall length is 2.5 feet. The rotor is 4.6” in diameter and weighs 1.3 lb. 3200 3000 – Eliminates gearboxÆeliminates lube oil system Can eliminate shaft sealÆhermetic turbine/generator Overhung rotor eliminates coupling/field alignment 2600 110 – ModularityÆFamily of designs 130% 125% 120% 115% 110% 105% 100% VPC Relatively Low Jet Velocity 80% 200 Predicted Power (kW) R134a Performance vs Geothermal Return Temperature 97% Gen, 98% Gear, 77% Pump, 95% Motor, 80 °F Tcond, 100 MMBTU/hr @ 250 °F inlet, 160 °F return VPT NOZZLE (1 of 10) LNG FLOW VPT TURBINE ROTOR 115 120 125 130 135 Return Temperature (°F) 145 150 155 160 220 240 260 280 300 320 340 360 380 400 ORC – More power from resourceÆproject economics – Eliminates separator/preheater Brine Temperature (°F) 3 140 Discrete Nozzles Small dropletsÆclose-coupling of phasesÆefficient acceleration • Unlimited Pressure Ratio • Equations derived at JPL. Experimentally verified. Axial Impulse Rotor: Two-Phase Kinetic EnergyÆShaft Power TWO-PHASE JET FROM NOZZLE Relatively low jet velocities – high momentum of liquid working fluid • Low operating speed – 3600 or 1800 rpm (synchronous speeds) • Below erosion threshold 8 7 6 5 4 3 2 1 0 A DOE program has been awarded for a 1 MW VPC to be installed at Coso Geothermal. The heat source is 225 °F brine separated from the flash. Due to the high TDS, the heat exchanger will be a shell-and-tube type. Impulse Turbine GENERATOR LNG INLET PLENUM The system efficiency gain is 7-8%. – Low runaway speed. Low thrust load. – Shaft seal against low pressure – No close clearances with rotorPDF Image | ORC Kalina Cycle Euler and Variable Pulse Turbine

PDF Search Title:

ORC Kalina Cycle Euler and Variable Pulse TurbineOriginal File Name Searched:

Geothermal_Resources_Council_2009_Poster.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |