PDF Publication Title:

Text from PDF Page: 005

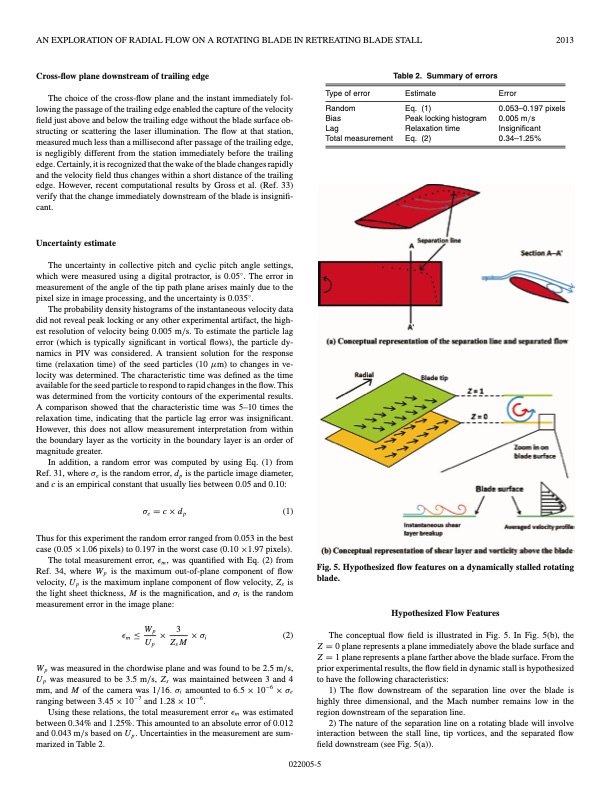

AN EXPLORATION OF RADIAL FLOW ON A ROTATING BLADE IN RETREATING BLADE STALL 2013 Cross-flow plane downstream of trailing edge The choice of the cross-flow plane and the instant immediately fol- lowing the passage of the trailing edge enabled the capture of the velocity field just above and below the trailing edge without the blade surface ob- structing or scattering the laser illumination. The flow at that station, measured much less than a millisecond after passage of the trailing edge, is negligibly different from the station immediately before the trailing edge. Certainly, it is recognized that the wake of the blade changes rapidly and the velocity field thus changes within a short distance of the trailing edge. However, recent computational results by Gross et al. (Ref. 33) verify that the change immediately downstream of the blade is insignifi- cant. Uncertainty estimate The uncertainty in collective pitch and cyclic pitch angle settings, which were measured using a digital protractor, is 0.05◦. The error in measurement of the angle of the tip path plane arises mainly due to the pixel size in image processing, and the uncertainty is 0.035◦. The probability density histograms of the instantaneous velocity data did not reveal peak locking or any other experimental artifact, the high- est resolution of velocity being 0.005 m/s. To estimate the particle lag error (which is typically significant in vortical flows), the particle dy- namics in PIV was considered. A transient solution for the response time (relaxation time) of the seed particles (10 μm) to changes in ve- locity was determined. The characteristic time was defined as the time available for the seed particle to respond to rapid changes in the flow. This was determined from the vorticity contours of the experimental results. A comparison showed that the characteristic time was 5–10 times the relaxation time, indicating that the particle lag error was insignificant. However, this does not allow measurement interpretation from within the boundary layer as the vorticity in the boundary layer is an order of magnitude greater. In addition, a random error was computed by using Eq. (1) from Ref. 31, where σe is the random error, dp is the particle image diameter, and c is an empirical constant that usually lies between 0.05 and 0.10: σe =c×dp (1) Thus for this experiment the random error ranged from 0.053 in the best case (0.05 ×1.06 pixels) to 0.197 in the worst case (0.10 ×1.97 pixels). The total measurement error, εm, was quantified with Eq. (2) from Ref. 34, where Wp is the maximum out-of-plane component of flow velocity, Up is the maximum inplane component of flow velocity, Zs is the light sheet thickness, M is the magnification, and σi is the random measurement error in the image plane: εm≤Wp×3×σi (2) Up ZsM Wp was measured in the chordwise plane and was found to be 2.5 m/s, Up was measured to be 3.5 m/s, Zs was maintained between 3 and 4 mm, and M of the camera was 1/16. σi amounted to 6.5 × 10−6 × σe ranging between 3.45 × 10−7 and 1.28 × 10−6. Using these relations, the total measurement error εm was estimated between 0.34% and 1.25%. This amounted to an absolute error of 0.012 and 0.043 m/s based on Up . Uncertainties in the measurement are sum- marized in Table 2. Type of error Random Bias Lag Total measurement Table 2. Summary of errors Estimate Eq. (1) Peak locking histogram Relaxation time Eq. (2) Error 0.053–0.197 pixels 0.005 m/s Insignificant 0.34–1.25% 022005-5 Fig. 5. Hypothesized flow features on a dynamically stalled rotating blade. Hypothesized Flow Features The conceptual flow field is illustrated in Fig. 5. In Fig. 5(b), the Z = 0 plane represents a plane immediately above the blade surface and Z = 1 plane represents a plane farther above the blade surface. From the prior experimental results, the flow field in dynamic stall is hypothesized to have the following characteristics: 1) The flow downstream of the separation line over the blade is highly three dimensional, and the Mach number remains low in the region downstream of the separation line. 2) The nature of the separation line on a rotating blade will involve interaction between the stall line, tip vortices, and the separated flow field downstream (see Fig. 5(a)).PDF Image | Radial Flow Rotating Blade Retreating Blade Stall

PDF Search Title:

Radial Flow Rotating Blade Retreating Blade StallOriginal File Name Searched:

JAHS_Radial Flow.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |