PDF Publication Title:

Text from PDF Page: 004

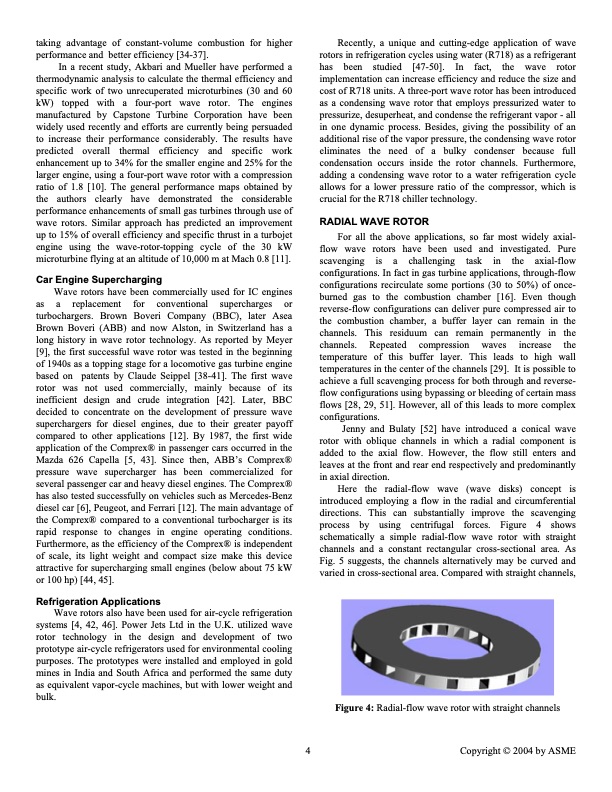

taking advantage of constant-volume combustion for higher performance and better efficiency [34-37]. In a recent study, Akbari and Mueller have performed a thermodynamic analysis to calculate the thermal efficiency and specific work of two unrecuperated microturbines (30 and 60 kW) topped with a four-port wave rotor. The engines manufactured by Capstone Turbine Corporation have been widely used recently and efforts are currently being persuaded to increase their performance considerably. The results have predicted overall thermal efficiency and specific work enhancement up to 34% for the smaller engine and 25% for the larger engine, using a four-port wave rotor with a compression ratio of 1.8 [10]. The general performance maps obtained by the authors clearly have demonstrated the considerable performance enhancements of small gas turbines through use of wave rotors. Similar approach has predicted an improvement up to 15% of overall efficiency and specific thrust in a turbojet engine using the wave-rotor-topping cycle of the 30 kW microturbine flying at an altitude of 10,000 m at Mach 0.8 [11]. Car Engine Supercharging Wave rotors have been commercially used for IC engines as a replacement for conventional supercharges or turbochargers. Brown Boveri Company (BBC), later Asea Brown Boveri (ABB) and now Alston, in Switzerland has a long history in wave rotor technology. As reported by Meyer [9], the first successful wave rotor was tested in the beginning of 1940s as a topping stage for a locomotive gas turbine engine based on patents by Claude Seippel [38-41]. The first wave rotor was not used commercially, mainly because of its inefficient design and crude integration [42]. Later, BBC decided to concentrate on the development of pressure wave superchargers for diesel engines, due to their greater payoff compared to other applications [12]. By 1987, the first wide application of the Comprex® in passenger cars occurred in the Mazda 626 Capella [5, 43]. Since then, ABB’s Comprex® pressure wave supercharger has been commercialized for several passenger car and heavy diesel engines. The Comprex® has also tested successfully on vehicles such as Mercedes-Benz diesel car [6], Peugeot, and Ferrari [12]. The main advantage of the Comprex® compared to a conventional turbocharger is its rapid response to changes in engine operating conditions. Furthermore, as the efficiency of the Comprex® is independent of scale, its light weight and compact size make this device attractive for supercharging small engines (below about 75 kW or 100 hp) [44, 45]. Refrigeration Applications Wave rotors also have been used for air-cycle refrigeration systems [4, 42, 46]. Power Jets Ltd in the U.K. utilized wave rotor technology in the design and development of two prototype air-cycle refrigerators used for environmental cooling purposes. The prototypes were installed and employed in gold mines in India and South Africa and performed the same duty as equivalent vapor-cycle machines, but with lower weight and bulk. Recently, a unique and cutting-edge application of wave rotors in refrigeration cycles using water (R718) as a refrigerant has been studied [47-50]. In fact, the wave rotor implementation can increase efficiency and reduce the size and cost of R718 units. A three-port wave rotor has been introduced as a condensing wave rotor that employs pressurized water to pressurize, desuperheat, and condense the refrigerant vapor - all in one dynamic process. Besides, giving the possibility of an additional rise of the vapor pressure, the condensing wave rotor eliminates the need of a bulky condenser because full condensation occurs inside the rotor channels. Furthermore, adding a condensing wave rotor to a water refrigeration cycle allows for a lower pressure ratio of the compressor, which is crucial for the R718 chiller technology. RADIAL WAVE ROTOR For all the above applications, so far most widely axial- flow wave rotors have been used and investigated. Pure scavenging is a challenging task in the axial-flow configurations. In fact in gas turbine applications, through-flow configurations recirculate some portions (30 to 50%) of once- burned gas to the combustion chamber [16]. Even though reverse-flow configurations can deliver pure compressed air to the combustion chamber, a buffer layer can remain in the channels. This residuum can remain permanently in the channels. Repeated compression waves increase the temperature of this buffer layer. This leads to high wall temperatures in the center of the channels [29]. It is possible to achieve a full scavenging process for both through and reverse- flow configurations using bypassing or bleeding of certain mass flows [28, 29, 51]. However, all of this leads to more complex configurations. Jenny and Bulaty [52] have introduced a conical wave rotor with oblique channels in which a radial component is added to the axial flow. However, the flow still enters and leaves at the front and rear end respectively and predominantly in axial direction. Here the radial-flow wave (wave disks) concept is introduced employing a flow in the radial and circumferential directions. This can substantially improve the scavenging process by using centrifugal forces. Figure 4 shows schematically a simple radial-flow wave rotor with straight channels and a constant rectangular cross-sectional area. As Fig. 5 suggests, the channels alternatively may be curved and varied in cross-sectional area. Compared with straight channels, Figure 4: Radial-flow wave rotor with straight channels Copyright © 2004 by ASME 4PDF Image | RADIAL-FLOW WAVE ROTOR CONCEPTS, UNCONVENTIONAL DESIGNS

PDF Search Title:

RADIAL-FLOW WAVE ROTOR CONCEPTS, UNCONVENTIONAL DESIGNSOriginal File Name Searched:

PiechnaAkbariIancuMuellerIMECE2004-59022.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |