PDF Publication Title:

Text from PDF Page: 002

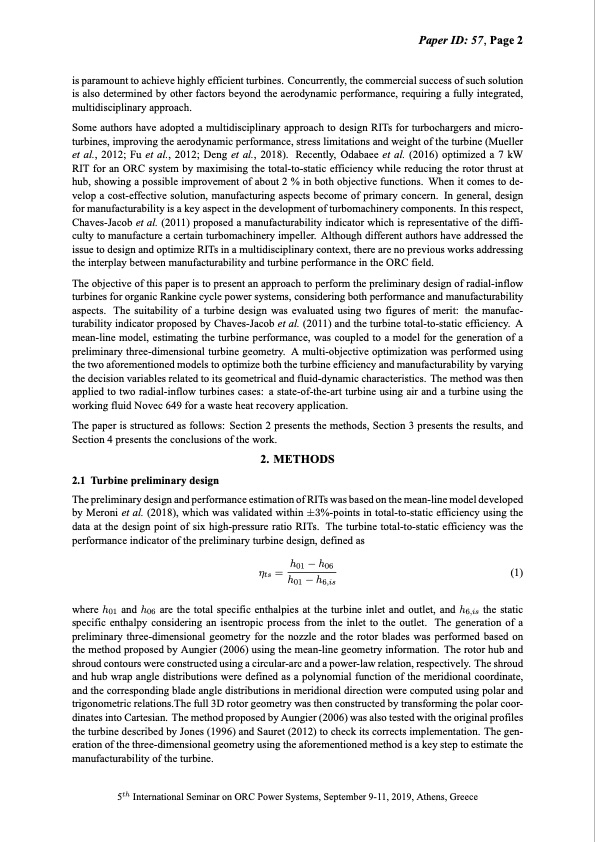

is paramount to achieve highly efficient turbines. Concurrently, the commercial success of such solution is also determined by other factors beyond the aerodynamic performance, requiring a fully integrated, multidisciplinary approach. Some authors have adopted a multidisciplinary approach to design RITs for turbochargers and micro- turbines, improving the aerodynamic performance, stress limitations and weight of the turbine (Mueller et al., 2012; Fu et al., 2012; Deng et al., 2018). Recently, Odabaee et al. (2016) optimized a 7 kW RIT for an ORC system by maximising the total-to-static efficiency while reducing the rotor thrust at hub, showing a possible improvement of about 2 % in both objective functions. When it comes to de- velop a cost-effective solution, manufacturing aspects become of primary concern. In general, design for manufacturability is a key aspect in the development of turbomachinery components. In this respect, Chaves-Jacob et al. (2011) proposed a manufacturability indicator which is representative of the diffi- culty to manufacture a certain turbomachinery impeller. Although different authors have addressed the issue to design and optimize RITs in a multidisciplinary context, there are no previous works addressing the interplay between manufacturability and turbine performance in the ORC field. The objective of this paper is to present an approach to perform the preliminary design of radial-inflow turbines for organic Rankine cycle power systems, considering both performance and manufacturability aspects. The suitability of a turbine design was evaluated using two figures of merit: the manufac- turability indicator proposed by Chaves-Jacob et al. (2011) and the turbine total-to-static efficiency. A mean-line model, estimating the turbine performance, was coupled to a model for the generation of a preliminary three-dimensional turbine geometry. A multi-objective optimization was performed using the two aforementioned models to optimize both the turbine efficiency and manufacturability by varying the decision variables related to its geometrical and fluid-dynamic characteristics. The method was then applied to two radial-inflow turbines cases: a state-of-the-art turbine using air and a turbine using the working fluid Novec 649 for a waste heat recovery application. The paper is structured as follows: Section 2 presents the methods, Section 3 presents the results, and Section 4 presents the conclusions of the work. 2. METHODS 2.1 Turbine preliminary design The preliminary design and performance estimation of RITs was based on the mean-line model developed by Meroni et al. (2018), which was validated within ±3%-points in total-to-static efficiency using the data at the design point of six high-pressure ratio RITs. The turbine total-to-static efficiency was the performance indicator of the preliminary turbine design, defined as ηts = h01 − h06 (1) h01 − h6,is where h01 and h06 are the total specific enthalpies at the turbine inlet and outlet, and h6,is the static specific enthalpy considering an isentropic process from the inlet to the outlet. The generation of a preliminary three-dimensional geometry for the nozzle and the rotor blades was performed based on the method proposed by Aungier (2006) using the mean-line geometry information. The rotor hub and shroud contours were constructed using a circular-arc and a power-law relation, respectively. The shroud and hub wrap angle distributions were defined as a polynomial function of the meridional coordinate, and the corresponding blade angle distributions in meridional direction were computed using polar and trigonometric relations.The full 3D rotor geometry was then constructed by transforming the polar coor- dinates into Cartesian. The method proposed by Aungier (2006) was also tested with the original profiles the turbine described by Jones (1996) and Sauret (2012) to check its corrects implementation. The gen- eration of the three-dimensional geometry using the aforementioned method is a key step to estimate the manufacturability of the turbine. Paper ID: 57, Page 2 5th International Seminar on ORC Power Systems, September 9-11, 2019, Athens, GreecePDF Image | RADIAL-INFLOW TURBINES FOR ORGANIC RANKINE CYCLE POWER

PDF Search Title:

RADIAL-INFLOW TURBINES FOR ORGANIC RANKINE CYCLE POWEROriginal File Name Searched:

design-radial-inflow-turbine-for-orc.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |