PDF Publication Title:

Text from PDF Page: 005

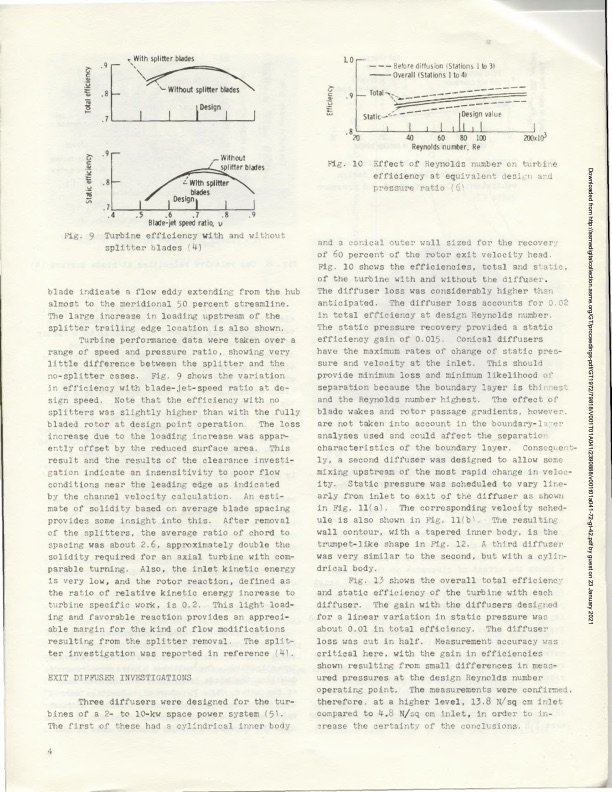

Fig. 9 7 .4 .5 .6 .7 .8 .9 Blade-jet speed ratio, v Turbine efficiency with and without splitter blades (4) C 9 8 .7 With splitter blades Without splatter blades Design ,..Without splatter blades With splItter blades Design LO ---Before diffusion (Stations 1 to 3) Overall (Stations 1 to 4) 9Total,\i—__-------- Statics— Design value 81_I1 1III,1 20 40 60 80 100 200x103 Reynolds number, Re Fig. 10 Effect of Reynolds number on turbine efficiency at equivalent desiz_n and pressure ratio ?5! and a conical outer wall sized for the recovery of 60 percent of the rotor exit velocity head. Fig. 10 shows the efficiencies, total and static, of the turbine with and without the diffuser. The diffuser loss was considerably higher than anticipated. The diffuser loss accounts for 0.02 in total efficiency at design Reynolds number. The static pressure recovery provided a static efficiency gain of 0.015. Conical diffusers have the maximum rates of change of static pres- sure and velocity at the inlet. This should provide minimum loss and minimum likelihood of separation because the boundary layer i s thinnest and the Reynolds number highest. The effect of blade wakes and rotor passage gradients, however. are not taken into account in the boundary-layer analyses used and could affect the separation characteristics of the boundary layer. Consequent- ly, a second diffuser was designed to allow some mixing upstream of the most rapid change in veloc- ity. Static pressure was scheduled to vary line- arly from inlet to exit of the diffuser as shown in Fig. 11(a). The corresponding velocity sched- ule is also shown in Fig. 11(bl. The resulting wall contour, with a tapered inner body, is the trumpet-like shape in Fig. 12. A third diffuser was very similar to the second, but with a cylin- drical body. Fig. 13 shows the overall total efficiency and static efficiency of the turbine with each diffuser. The gain with the diffusers designed for a linear variation in static pressure was about 0.01 in total efficiency. The diffuser loss was cut in half. Measurement accuracy was critical here, with the gain in efficiencies shown resulting from small differences in meas- ured pressures at the design Reynolds number operating point. The measurements were confirmed, therefore, at a higher level, 13.8 N/sq cm inlet compared to 4 . 8 N/sq cm inlet, in order to in- crease the certainty of the conclusions. s U .9 su 8 blade indicate a flow eddy extending from the hub almost to the meridional 50 percent streamline. The large increase in loading upstream of the splitter trailing edge location is also shown. Turbine performance data were taken over a range of speed and pressure ratio, showing very little difference between the splitter and the no-splitter cases. Fig. 9 shows the variation in efficiency with blade-jet-speed ratio at de- sign speed. Note that the efficiency with no splitters was slightly higher than with the fully bladed rotor at design point operation. The loss increase due to the loading increase was appar- ently offset by the reduced surface area. This result and the results of the clearance investi- gation indicate an insensitivity to poor flow conditions near the leading edge as indicated by the channel velocity calculation. An esti- mate of solidity based on average blade spacing provides some insight into this. After removal of the splitters, the average ratio of chord to spacing was about 2.6, approximately double the solidity required for an axial turbine with com- parable turning. Also, the inlet kinetic energy is very low, and the rotor reaction, defined as the ratio of relative kinetic energy increase to turbine specific work, is 0.2. This light load- ing and favorable reaction provides an appreci- able margin for the kind of flow modifications resulting from the splitter removal. The split- ter investigation was reported in reference (4). EXIT DIFFUSER INVESTIGATIONS Three diffusers were designed for the tur- bines of a 2- to 10-kw space power system (5). The first of these had a cylindrical inner body 4 Downloaded from http://asmedigitalcollection.asme.org/GT/proceedings-pdf/GT1972/79818/V001T01A041/2390888/v001t01a041-72-gt-42.pdf by guest on 23 January 2021PDF Image | Recent Radial Turbine Research at Nasa Lewis 1972

PDF Search Title:

Recent Radial Turbine Research at Nasa Lewis 1972Original File Name Searched:

v001t01a041-72-gt-42.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |