PDF Publication Title:

Text from PDF Page: 013

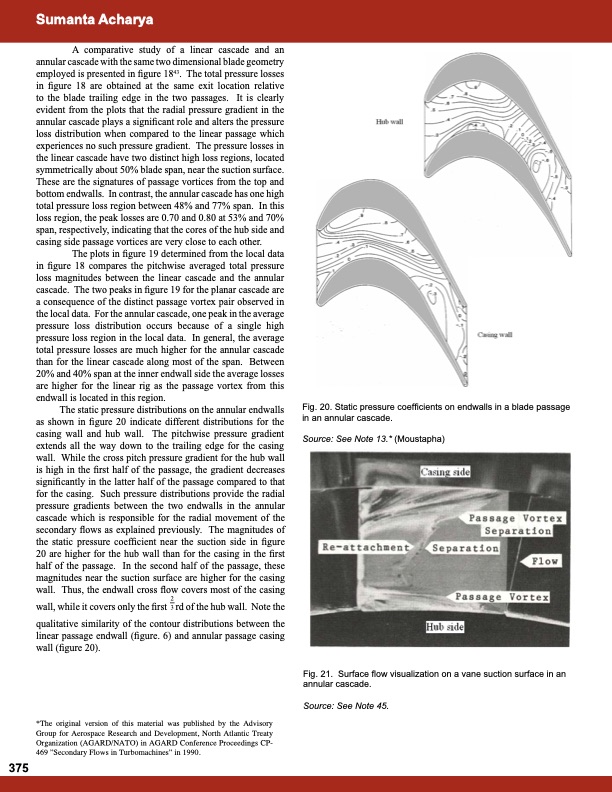

Sumanta Acharya A comparative study of a linear cascade and an annular cascade with the same two dimensional blade geometry employed is presented in figure 1843. The total pressure losses in figure 18 are obtained at the same exit location relative to the blade trailing edge in the two passages. It is clearly evident from the plots that the radial pressure gradient in the annular cascade plays a significant role and alters the pressure loss distribution when compared to the linear passage which experiences no such pressure gradient. The pressure losses in the linear cascade have two distinct high loss regions, located symmetrically about 50% blade span, near the suction surface. These are the signatures of passage vortices from the top and bottom endwalls. In contrast, the annular cascade has one high total pressure loss region between 48% and 77% span. In this loss region, the peak losses are 0.70 and 0.80 at 53% and 70% span, respectively, indicating that the cores of the hub side and casing side passage vortices are very close to each other. The plots in figure 19 determined from the local data in figure 18 compares the pitchwise averaged total pressure loss magnitudes between the linear cascade and the annular cascade. The two peaks in figure 19 for the planar cascade are a consequence of the distinct passage vortex pair observed in the local data. For the annular cascade, one peak in the average pressure loss distribution occurs because of a single high pressure loss region in the local data. In general, the average total pressure losses are much higher for the annular cascade than for the linear cascade along most of the span. Between 20% and 40% span at the inner endwall side the average losses are higher for the linear rig as the passage vortex from this endwall is located in this region. The static pressure distributions on the annular endwalls as shown in figure 20 indicate different distributions for the casing wall and hub wall. The pitchwise pressure gradient extends all the way down to the trailing edge for the casing wall. While the cross pitch pressure gradient for the hub wall is high in the first half of the passage, the gradient decreases significantly in the latter half of the passage compared to that for the casing. Such pressure distributions provide the radial pressure gradients between the two endwalls in the annular cascade which is responsible for the radial movement of the secondary flows as explained previously. The magnitudes of the static pressure coefficient near the suction side in figure 20 are higher for the hub wall than for the casing in the first half of the passage. In the second half of the passage, these magnitudes near the suction surface are higher for the casing wall. Thus, the endwall cross flow covers most of the casing wall, while it covers only the first 23 rd of the hub wall. Note the qualitative similarity of the contour distributions between the linear passage endwall (figure. 6) and annular passage casing wall (figure 20). *The original version of this material was published by the Advisory Group for Aerospace Research and Development, North Atlantic Treaty Organization (AGARD/NATO) in AGARD Conference Proceedings CP- 469 ”Secondary Flows in Turbomachines” in 1990. Fig. 20. Static pressure coefficients on endwalls in a blade passage in an annular cascade. Source: See Note 13.* (Moustapha) 375 Fig. 21. Surface flow visualization on a vane suction surface in an annular cascade. Source: See Note 45.PDF Image | Turbine Blade Aerodynamics

PDF Search Title:

Turbine Blade AerodynamicsOriginal File Name Searched:

turbine-blade-aerodynamics.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |