PDF Publication Title:

Text from PDF Page: 015

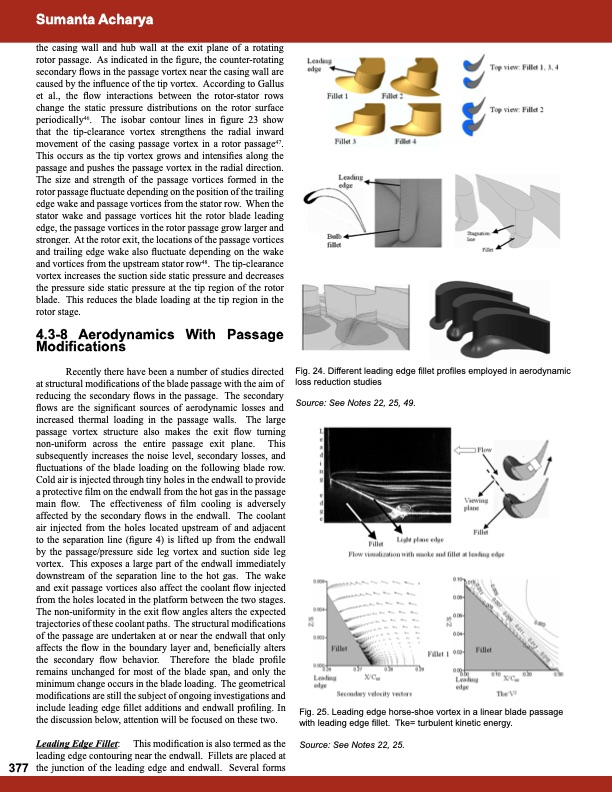

Sumanta Acharya the casing wall and hub wall at the exit plane of a rotating rotor passage. As indicated in the figure, the counter-rotating secondary flows in the passage vortex near the casing wall are caused by the influence of the tip vortex. According to Gallus et al., the flow interactions between the rotor-stator rows change the static pressure distributions on the rotor surface periodically46. The isobar contour lines in figure 23 show that the tip-clearance vortex strengthens the radial inward movement of the casing passage vortex in a rotor passage47. This occurs as the tip vortex grows and intensifies along the passage and pushes the passage vortex in the radial direction. The size and strength of the passage vortices formed in the rotor passage fluctuate depending on the position of the trailing edge wake and passage vortices from the stator row. When the stator wake and passage vortices hit the rotor blade leading edge, the passage vortices in the rotor passage grow larger and stronger. At the rotor exit, the locations of the passage vortices and trailing edge wake also fluctuate depending on the wake and vortices from the upstream stator row48. The tip-clearance vortex increases the suction side static pressure and decreases the pressure side static pressure at the tip region of the rotor blade. This reduces the blade loading at the tip region in the rotor stage. 4.3-8 Aerodynamics With Passage Modifications Recently there have been a number of studies directed at structural modifications of the blade passage with the aim of reducing the secondary flows in the passage. The secondary flows are the significant sources of aerodynamic losses and increased thermal loading in the passage walls. The large passage vortex structure also makes the exit flow turning non-uniform across the entire passage exit plane. This subsequently increases the noise level, secondary losses, and fluctuations of the blade loading on the following blade row. Cold air is injected through tiny holes in the endwall to provide a protective film on the endwall from the hot gas in the passage main flow. The effectiveness of film cooling is adversely affected by the secondary flows in the endwall. The coolant air injected from the holes located upstream of and adjacent to the separation line (figure 4) is lifted up from the endwall by the passage/pressure side leg vortex and suction side leg vortex. This exposes a large part of the endwall immediately downstream of the separation line to the hot gas. The wake and exit passage vortices also affect the coolant flow injected from the holes located in the platform between the two stages. The non-uniformity in the exit flow angles alters the expected trajectories of these coolant paths. The structural modifications of the passage are undertaken at or near the endwall that only affects the flow in the boundary layer and, beneficially alters the secondary flow behavior. Therefore the blade profile remains unchanged for most of the blade span, and only the minimum change occurs in the blade loading. The geometrical modifications are still the subject of ongoing investigations and include leading edge fillet additions and endwall profiling. In the discussion below, attention will be focused on these two. Fig. 24. Different leading edge fillet profiles employed in aerodynamic loss reduction studies Source: See Notes 22, 25, 49. Fig. 25. Leading edge horse-shoe vortex in a linear blade passage with leading edge fillet. Tke= turbulent kinetic energy. Leading Edge Fillet: This modification is also termed as the Source: See Notes 22, 25. leading edge contouring near the endwall. Fillets are placed at 377 the junction of the leading edge and endwall. Several formsPDF Image | Turbine Blade Aerodynamics

PDF Search Title:

Turbine Blade AerodynamicsOriginal File Name Searched:

turbine-blade-aerodynamics.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |