PDF Publication Title:

Text from PDF Page: 019

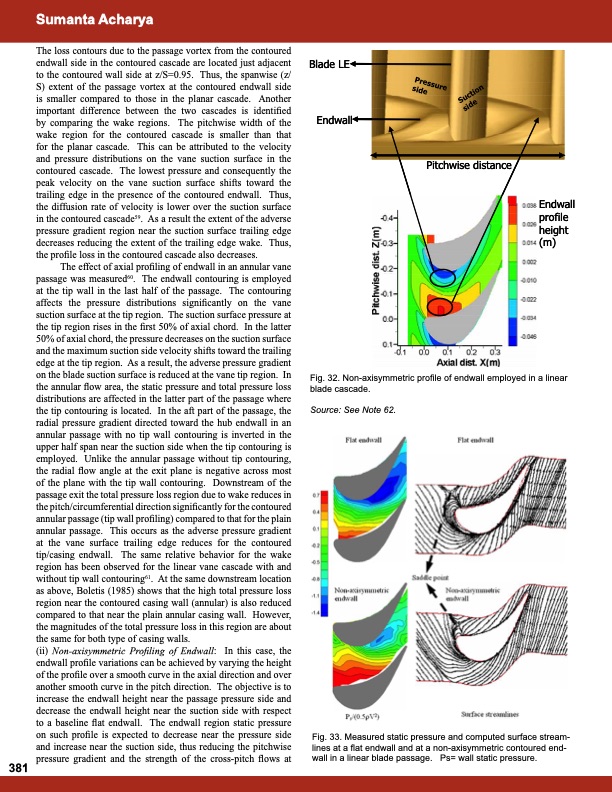

Sumanta Acharya The loss contours due to the passage vortex from the contoured endwall side in the contoured cascade are located just adjacent to the contoured wall side at z/S=0.95. Thus, the spanwise (z/ S) extent of the passage vortex at the contoured endwall side is smaller compared to those in the planar cascade. Another important difference between the two cascades is identified by comparing the wake regions. The pitchwise width of the wake region for the contoured cascade is smaller than that for the planar cascade. This can be attributed to the velocity and pressure distributions on the vane suction surface in the contoured cascade. The lowest pressure and consequently the peak velocity on the vane suction surface shifts toward the trailing edge in the presence of the contoured endwall. Thus, the diffusion rate of velocity is lower over the suction surface in the contoured cascade59. As a result the extent of the adverse pressure gradient region near the suction surface trailing edge decreases reducing the extent of the trailing edge wake. Thus, the profile loss in the contoured cascade also decreases. The effect of axial profiling of endwall in an annular vane passage was measured60. The endwall contouring is employed at the tip wall in the last half of the passage. The contouring affects the pressure distributions significantly on the vane suction surface at the tip region. The suction surface pressure at the tip region rises in the first 50% of axial chord. In the latter 50% of axial chord, the pressure decreases on the suction surface and the maximum suction side velocity shifts toward the trailing edge at the tip region. As a result, the adverse pressure gradient on the blade suction surface is reduced at the vane tip region. In the annular flow area, the static pressure and total pressure loss distributions are affected in the latter part of the passage where the tip contouring is located. In the aft part of the passage, the radial pressure gradient directed toward the hub endwall in an annular passage with no tip wall contouring is inverted in the upper half span near the suction side when the tip contouring is employed. Unlike the annular passage without tip contouring, the radial flow angle at the exit plane is negative across most of the plane with the tip wall contouring. Downstream of the passage exit the total pressure loss region due to wake reduces in the pitch/circumferential direction significantly for the contoured annular passage (tip wall profiling) compared to that for the plain annular passage. This occurs as the adverse pressure gradient at the vane surface trailing edge reduces for the contoured tip/casing endwall. The same relative behavior for the wake region has been observed for the linear vane cascade with and without tip wall contouring61. At the same downstream location as above, Boletis (1985) shows that the high total pressure loss region near the contoured casing wall (annular) is also reduced compared to that near the plain annular casing wall. However, the magnitudes of the total pressure loss in this region are about the same for both type of casing walls. (ii) Non-axisymmetric Profiling of Endwall: In this case, the endwall profile variations can be achieved by varying the height of the profile over a smooth curve in the axial direction and over another smooth curve in the pitch direction. The objective is to increase the endwall height near the passage pressure side and decrease the endwall height near the suction side with respect to a baseline flat endwall. The endwall region static pressure on such profile is expected to decrease near the pressure side and increase near the suction side, thus reducing the pitchwise 381 pressure gradient and the strength of the cross-pitch flows at Blade LE Endwall P e e P e e i t i t c h c h w i s d i s w i s d i s t t a a n n c c Endwall profile height (m) Fig. 32. Non-axisymmetric profile of endwall employed in a linear blade cascade. Source: See Note 62. Fig. 33. Measured static pressure and computed surface stream- lines at a flat endwall and at a non-axisymmetric contoured end- wall in a linear blade passage. Ps= wall static pressure. Pressure side Suction sidePDF Image | Turbine Blade Aerodynamics

PDF Search Title:

Turbine Blade AerodynamicsOriginal File Name Searched:

turbine-blade-aerodynamics.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |