PDF Publication Title:

Text from PDF Page: 077

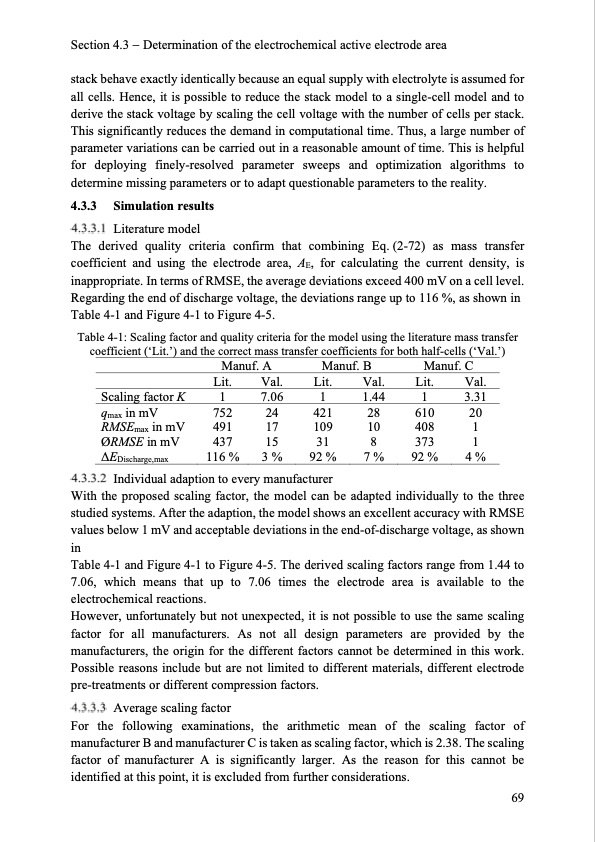

Section 4.3 Determination of the electrochemical active electrode area stack behave exactly identically because an equal supply with electrolyte is assumed for all cells. Hence, it is possible to reduce the stack model to a single-cell model and to derive the stack voltage by scaling the cell voltage with the number of cells per stack. This significantly reduces the demand in computational time. Thus, a large number of parameter variations can be carried out in a reasonable amount of time. This is helpful for deploying finely-resolved parameter sweeps and optimization algorithms to determine missing parameters or to adapt questionable parameters to the reality. 4.3.3 Simulation results Literature model The derived quality criteria confirm that combining Eq. (2-72) as mass transfer coefficient and using the electrode area, AE, for calculating the current density, is inappropriate. In terms of RMSE, the average deviations exceed 400 mV on a cell level. Regarding the end of discharge voltage, the deviations range up to 116 %, as shown in Table 4-1 and Figure 4-1 to Figure 4-5. Table 4-1: Scaling factor and quality criteria for the model using the literature mass transfer coefficient (‘Lit.’) and the correct mass transfer coefficients for both half-cells (‘Val.’) Manuf. A Manuf. B Manuf. C Scaling factor K qmax in mV RMSEmax in mV ØRMSE in mV ΔEDischarge,max Lit. 1 752 491 437 116 % V al. 7.06 24 17 15 3 % Lit. 1 421 109 31 92 % V al. 1.44 28 10 8 7 % Lit. 1 610 408 373 92 % V al. 3.31 20 1 1 4 % Individual adaption to every manufacturer With the proposed scaling factor, the model can be adapted individually to the three studied systems. After the adaption, the model shows an excellent accuracy with RMSE values below 1 mV and acceptable deviations in the end-of-discharge voltage, as shown in Table 4-1 and Figure 4-1 to Figure 4-5. The derived scaling factors range from 1.44 to 7.06, which means that up to 7.06 times the electrode area is available to the electrochemical reactions. However, unfortunately but not unexpected, it is not possible to use the same scaling factor for all manufacturers. As not all design parameters are provided by the manufacturers, the origin for the different factors cannot be determined in this work. Possible reasons include but are not limited to different materials, different electrode pre-treatments or different compression factors. Average scaling factor For the following examinations, the arithmetic mean of the scaling factor of manufacturer B and manufacturer C is taken as scaling factor, which is 2.38. The scaling factor of manufacturer A is significantly larger. As the reason for this cannot be identified at this point, it is excluded from further considerations. 69PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |