PDF Publication Title:

Text from PDF Page: 108

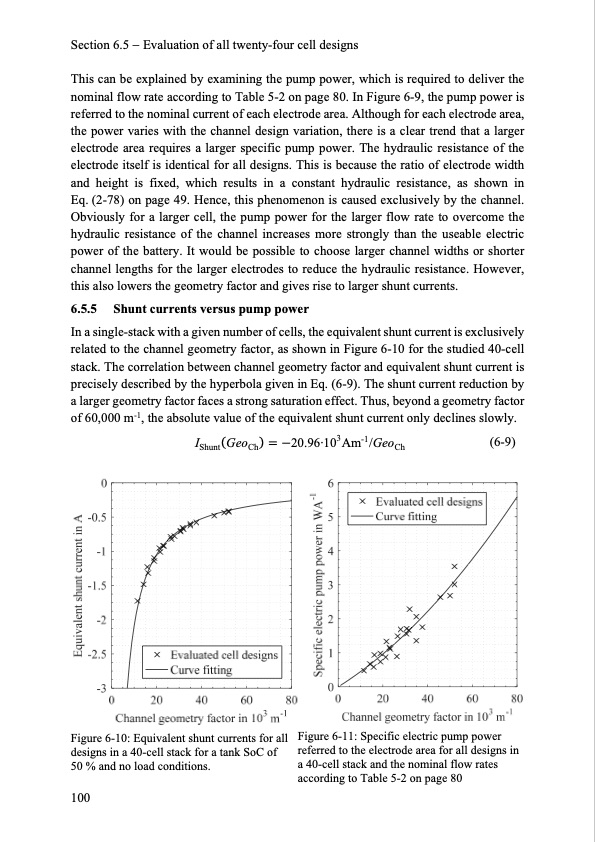

Section 6.5 Evaluation of all twenty-four cell designs This can be explained by examining the pump power, which is required to deliver the nominal flow rate according to Table 5-2 on page 80. In Figure 6-9, the pump power is referred to the nominal current of each electrode area. Although for each electrode area, the power varies with the channel design variation, there is a clear trend that a larger electrode area requires a larger specific pump power. The hydraulic resistance of the electrode itself is identical for all designs. This is because the ratio of electrode width and height is fixed, which results in a constant hydraulic resistance, as shown in Eq. (2-78) on page 49. Hence, this phenomenon is caused exclusively by the channel. Obviously for a larger cell, the pump power for the larger flow rate to overcome the hydraulic resistance of the channel increases more strongly than the useable electric power of the battery. It would be possible to choose larger channel widths or shorter channel lengths for the larger electrodes to reduce the hydraulic resistance. However, this also lowers the geometry factor and gives rise to larger shunt currents. 6.5.5 Shunt currents versus pump power In a single-stack with a given number of cells, the equivalent shunt current is exclusively related to the channel geometry factor, as shown in Figure 6-10 for the studied 40-cell stack. The correlation between channel geometry factor and equivalent shunt current is precisely described by the hyperbola given in Eq. (6-9). The shunt current reduction by a larger geometry factor faces a strong saturation effect. Thus, beyond a geometry factor of 60,000 m-1, the absolute value of the equivalent shunt current only declines slowly. IShuntGeoCh 20.96·103Am-1/GeoCh (6-9) Figure 6-10: Equivalent shunt currents for all designs in a 40-cell stack for a tank SoC of 50 % and no load conditions. Figure 6-11: Specific electric pump power referred to the electrode area for all designs in a 40-cell stack and the nominal flow rates according to Table 5-2 on page 80 100PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |