PDF Publication Title:

Text from PDF Page: 121

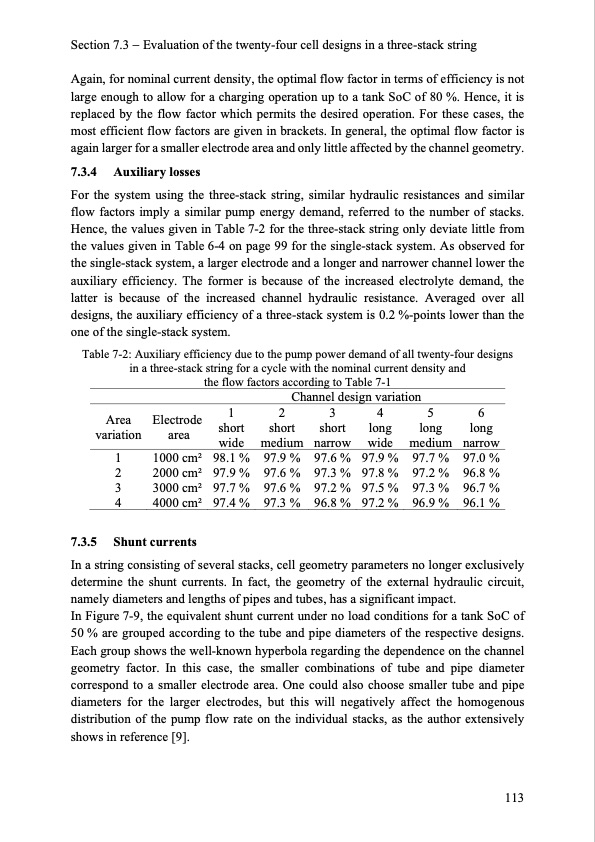

Section 7.3 Evaluation of the twenty-four cell designs in a three-stack string Again, for nominal current density, the optimal flow factor in terms of efficiency is not large enough to allow for a charging operation up to a tank SoC of 80 %. Hence, it is replaced by the flow factor which permits the desired operation. For these cases, the most efficient flow factors are given in brackets. In general, the optimal flow factor is again larger for a smaller electrode area and only little affected by the channel geometry. 7.3.4 Auxiliary losses For the system using the three-stack string, similar hydraulic resistances and similar flow factors imply a similar pump energy demand, referred to the number of stacks. Hence, the values given in Table 7-2 for the three-stack string only deviate little from the values given in Table 6-4 on page 99 for the single-stack system. As observed for the single-stack system, a larger electrode and a longer and narrower channel lower the auxiliary efficiency. The former is because of the increased electrolyte demand, the latter is because of the increased channel hydraulic resistance. Averaged over all designs, the auxiliary efficiency of a three-stack system is 0.2 %-points lower than the one of the single-stack system. Table 7-2: Auxiliary efficiency due to the pump power demand of all twenty-four designs in a three-stack string for a cycle with the nominal current density and the flow factors according to Table 7-1 Area Electrode Channel design variation 123456 short short short long long long wide medium narrow wide medium narrow variation area 98.1% 97.9% 97.6% 97.9% 97.7% 97.0% 97.9% 97.6% 97.3% 97.8% 97.2% 96.8% 97.7% 97.6% 97.2% 97.5% 97.3% 96.7% 97.4% 97.3% 96.8% 97.2% 96.9% 96.1% 1 1000 cm2 2 2000 cm2 3 3000 cm2 4 4000 cm2 7.3.5 Shunt currents In a string consisting of several stacks, cell geometry parameters no longer exclusively determine the shunt currents. In fact, the geometry of the external hydraulic circuit, namely diameters and lengths of pipes and tubes, has a significant impact. In Figure 7-9, the equivalent shunt current under no load conditions for a tank SoC of 50 % are grouped according to the tube and pipe diameters of the respective designs. Each group shows the well-known hyperbola regarding the dependence on the channel geometry factor. In this case, the smaller combinations of tube and pipe diameter correspond to a smaller electrode area. One could also choose smaller tube and pipe diameters for the larger electrodes, but this will negatively affect the homogenous distribution of the pump flow rate on the individual stacks, as the author extensively shows in reference [9]. 113PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |