PDF Publication Title:

Text from PDF Page: 128

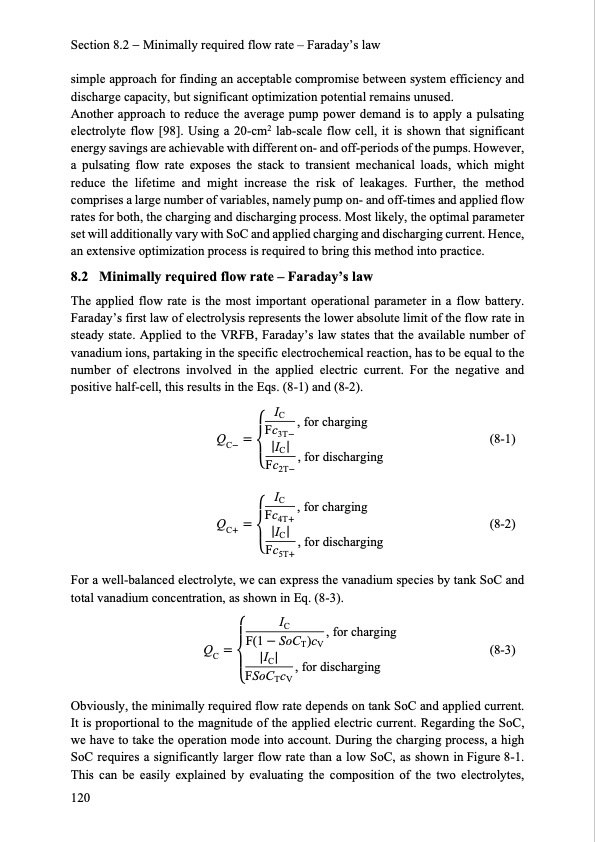

Section 8.2 Minimally required flow rate – Faraday’s law simple approach for finding an acceptable compromise between system efficiency and discharge capacity, but significant optimization potential remains unused. Another approach to reduce the average pump power demand is to apply a pulsating electrolyte flow [98]. Using a 20-cm2 lab-scale flow cell, it is shown that significant energy savings are achievable with different on- and off-periods of the pumps. However, a pulsating flow rate exposes the stack to transient mechanical loads, which might reduce the lifetime and might increase the risk of leakages. Further, the method comprises a large number of variables, namely pump on- and off-times and applied flow rates for both, the charging and discharging process. Most likely, the optimal parameter set will additionally vary with SoC and applied charging and discharging current. Hence, an extensive optimization process is required to bring this method into practice. 8.2 Minimally required flow rate – Faraday’s law The applied flow rate is the most important operational parameter in a flow battery. Faraday’s first law of electrolysis represents the lower absolute limit of the flow rate in steady state. Applied to the VRFB, Faraday’s law states that the available number of vanadium ions, partaking in the specific electrochemical reaction, has to be equal to the number of electrons involved in the applied electric current. For the negative and positive half-cell, this results in the Eqs. (8-1) and (8-2). IC , for charging Q Fc3T C |IC| , for discharging Fc2T IC , for charging Q Fc4T C |IC| , for discharging Fc5T (8-1) (8-2) For a well-balanced electrolyte, we can express the vanadium species by tank SoC and total vanadium concentration, as shown in Eq. (8-3). IC , for charging Q F(1 SoCT)cV C |IC| , for discharging FSoCT cV (8-3) Obviously, the minimally required flow rate depends on tank SoC and applied current. It is proportional to the magnitude of the applied electric current. Regarding the SoC, we have to take the operation mode into account. During the charging process, a high SoC requires a significantly larger flow rate than a low SoC, as shown in Figure 8-1. This can be easily explained by evaluating the composition of the two electrolytes, 120PDF Image | Model-based Design Vanadium Redox Flow Batteries

PDF Search Title:

Model-based Design Vanadium Redox Flow BatteriesOriginal File Name Searched:

10-5445IR1000070670.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |