PDF Publication Title:

Text from PDF Page: 007

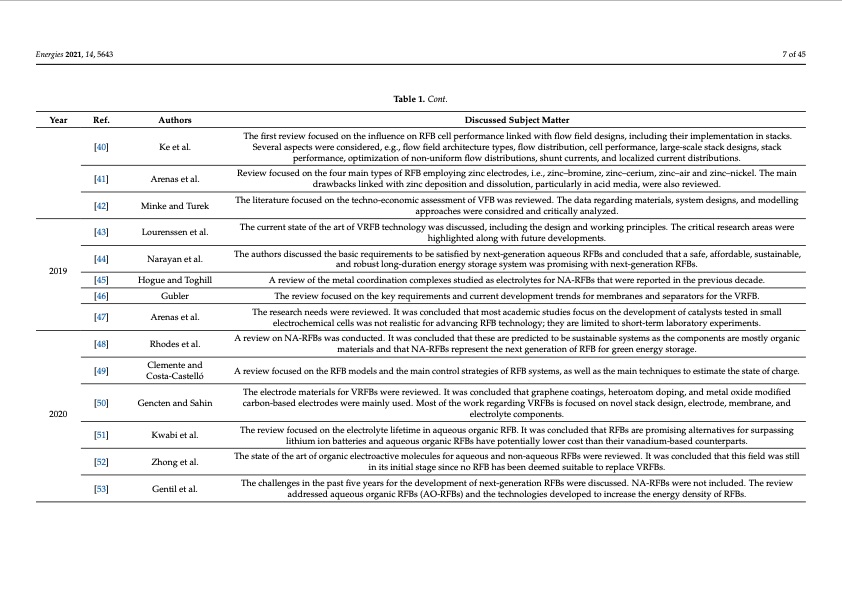

Energies 2021, 14, 5643 7 of 45 Table 1. Cont. Year Ref. [40] [41] [42] [43] [44] [45] [46] [47] [48] [49] [50] [51] [52] [53] Authors Ke et al. Arenas et al. Minke and Turek Lourenssen et al. Narayan et al. Hogue and Toghill Gubler Arenas et al. Rhodes et al. Clemente and Costa-Castelló Gencten and Sahin Kwabi et al. Zhong et al. Gentil et al. Discussed Subject Matter 2019 The first review focused on the influence on RFB cell performance linked with flow field designs, including their implementation in stacks. Several aspects were considered, e.g., flow field architecture types, flow distribution, cell performance, large-scale stack designs, stack performance, optimization of non-uniform flow distributions, shunt currents, and localized current distributions. Review focused on the four main types of RFB employing zinc electrodes, i.e., zinc–bromine, zinc–cerium, zinc–air and zinc–nickel. The main drawbacks linked with zinc deposition and dissolution, particularly in acid media, were also reviewed. The literature focused on the techno-economic assessment of VFB was reviewed. The data regarding materials, system designs, and modelling approaches were considred and critically analyzed. The current state of the art of VRFB technology was discussed, including the design and working principles. The critical research areas were highlighted along with future developments. The authors discussed the basic requirements to be satisfied by next-generation aqueous RFBs and concluded that a safe, affordable, sustainable, and robust long-duration energy storage system was promising with next-generation RFBs. A review of the metal coordination complexes studied as electrolytes for NA-RFBs that were reported in the previous decade. The review focused on the key requirements and current development trends for membranes and separators for the VRFB. The research needs were reviewed. It was concluded that most academic studies focus on the development of catalysts tested in small electrochemical cells was not realistic for advancing RFB technology; they are limited to short-term laboratory experiments. A review on NA-RFBs was conducted. It was concluded that these are predicted to be sustainable systems as the components are mostly organic materials and that NA-RFBs represent the next generation of RFB for green energy storage. A review focused on the RFB models and the main control strategies of RFB systems, as well as the main techniques to estimate the state of charge. The electrode materials for VRFBs were reviewed. It was concluded that graphene coatings, heteroatom doping, and metal oxide modified carbon-based electrodes were mainly used. Most of the work regarding VRFBs is focused on novel stack design, electrode, membrane, and electrolyte components. The review focused on the electrolyte lifetime in aqueous organic RFB. It was concluded that RFBs are promising alternatives for surpassing lithium ion batteries and aqueous organic RFBs have potentially lower cost than their vanadium-based counterparts. The state of the art of organic electroactive molecules for aqueous and non-aqueous RFBs were reviewed. It was concluded that this field was still in its initial stage since no RFB has been deemed suitable to replace VRFBs. The challenges in the past five years for the development of next-generation RFBs were discussed. NA-RFBs were not included. The review addressed aqueous organic RFBs (AO-RFBs) and the technologies developed to increase the energy density of RFBs. 2020PDF Image | PNNL Vanadium Redox Flow Battery Stack

PDF Search Title:

PNNL Vanadium Redox Flow Battery StackOriginal File Name Searched:

energies-14-05643-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Salgenx Redox Flow Battery Technology: Salt water flow battery technology with low cost and great energy density that can be used for power storage and thermal storage. Let us de-risk your production using our license. Our aqueous flow battery is less cost than Tesla Megapack and available faster. Redox flow battery. No membrane needed like with Vanadium, or Bromine. Salgenx flow battery

| CONTACT TEL: 608-238-6001 Email: greg@salgenx.com | RSS | AMP |